Technical Data

| Technical Specifications | Machine Models | |||||

| 330A | 330B | 430A | 430B | 530A | 530B | |

| Cutting Capacity 0° (Flat) (Length X Width) | 330*330mm | 330*330mm | 430*430mm | 430*430mm | 530*530mm | 530*530mm |

| Cutting Capacity 0° (Round) | 330mm | 330mm | 430mm | 430mm | 530mm | 530mm |

| Cutting Capacity 0° (Square) | 330*330mm | 330*330mm | 430*430mm | 430*430mm | 530*530mm | 530*530mm |

| Cutting Speed Infinitely Variable | 25/45/64/80m/min | 20~80m/min | 18~80m/min | 18~80m/min | 25/55/85m/min | 10~95m/min |

| Stop Length(Single Stroke) | 500mm | 500mm | 500mm | 500mm | 500mm | 500mm |

| Accuracy Of The Feeding(Single Feeding) | ±0.2mm | ±0.2mm | ±0.2mm | ±0.2mm | ±0.2mm | ±0.2mm |

| Saw Blade Size | 34*1.1*4115mm | 34*1.1*4115mm | 41*1.3*5080mm | 41*1.3*5080mm | 41*1.3*6240mm | 41*1.3*6240mm |

| Saw Blade Tension Type | Manual | Hydrualic | Manual | Hydrualic | Manual | Hydrualic |

| Workbench Height | 685mm | 685mm | 745mm | 745mm | 785mm | 785mm |

| Motor Rating Main Drive | 4kw | 4kw | 7.5kw | 7.5kw | 7.5kw | 7.5kw |

| Motor Rating Of Hydraulic Feed | 0.75kw | 0.75kw | 1.5kw | 1.5kw | 1.5kw | 1.5kw |

| Overall Dimensions (Length X Width X Height) | 2350*2220*1500mm | 2350*2220*1500mm | 2750*2220*1710mm | 2750*2250*1710mm | 3300*2000*2000mm | 3300*2000*2000mm |

| Weight(NET WEIGHT) | 1992kgs | 2054kgs | 2710kgs | 2778kgs | 3780kgs | 3780kgs |

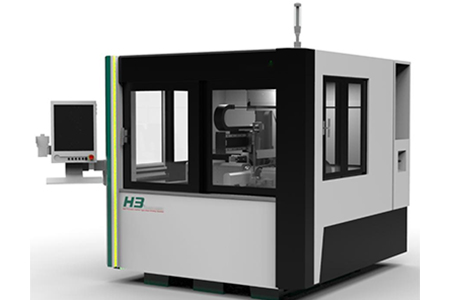

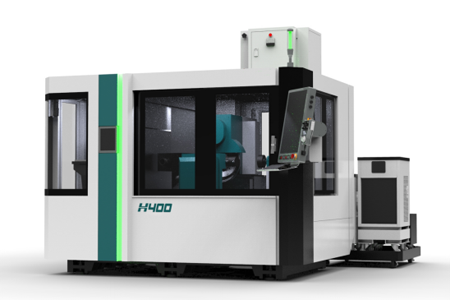

Product Introduction

This machine is an equipment for sawing metal materials with bimetallic saw blades. It has the advantages of compact structure, fast cutting speed, high precision, narrow saw gap, low noise, convenient operation, etc. It is a new energy-saving product that replaces circular saws and bow saws.

It is widely used for sawing various metal materials in various industries such as electromechanical, metallurgy, automobiles, bridges, and ships.

Accessories

- Standard Equipment(330A)

Saw-band

Work-piece counter

Band break control

Coolant system

Hydraulic clamping

Feed roller table 700 m (27 inch)

Linear stop

Operator instructions

- Optional Equipment (330B)

Bi-metallic band saw blade 34*1.1*4115 mm

2 meter roller table for 330 bandsaw

Chip conveyor and trolley for 330 bandsaw

Hydraulic blade tentioning for 330 bandsaw

Clamping force regulation at Hydraulic station

- Standard Equipment(430A)

Saw-band

Work-piece counter

Band break control

Coolant system

Hydraulic clamping

Feed roller table 700 m (27 inch)

Linear stop

Operator instructions

- Optional Equipment (430B)

Bi-metallic band saw blade 41*1.3*5080mm

2 meter roller table for 430 bandsaw

Chip conveyor and trolley for 430 bandsaw

Hydraulic blade tentioning for 430 bandsaw

Clamping force regulation at Hydraulic station

- Standard Equipment(530A)

Saw-band

Work-piece counter

Band break control

Coolant system

Hydraulic clamping

Feed roller table 700 m (27 inch)

Linear stop

Operator instructions

- Optional Equipment (530B)

Bi-metallic band saw blade 41*1.3*6240mm

2 meter roller table for 530 bandsaw

Chip conveyor and trolley for 530 bandsaw

Hydraulic blade tentioning for 530 bandsaw

Clamping force regulation at Hydraulic station

Advantages:

Continuous Innovation

High-tech enterprises, with a number of mature technical teams, annual research and development funds of 2 million, annual research and development of more than 12 new products, 20 national patent technology, continuous innovation.

6S Workshop Standard

36000 ㎡ workshop, 6S workshop standard, workshop through the ISO9001 quality system certification, with complete production equipment, products leave the factory after raw material inspection, process inspection, finished product inspection, products in line with GB and CE standard certification.

Self-built the Factory

Self-built the factory, through the whole industry chain, perfect casting factory, sheet metal factory, CNC machining center, cutting center, processing plant, accessories, the whole process of independent design and development, further reduce the cost, guarantee quality and improve the cost performance.

Our Parnter