Technical Data

| Technical Specifications | Unit | Machine Models | |||||||

| CL-75NC | CL-85NC | CL-100NC | CL-120NC | CL-150NC | CL-180NC | ||||

| Cutting Capacity For Round Bar ● | mm | 10-75 | 10-85 | 30-100 | 30-120 | 50-150 | 70-180 | ||

| Cutting Capacity For Square Bar■ | mm | 10~58 | 10~65 | 30~76 | 30~80 | 50~105 | 70~130 | ||

| Cutting Capacity For Round Pipe○ | mm | 10-75 | 10-85 | 30-100 | 30-120 | 50-150 | 70-180 | ||

| Cutting Capacity For Square Pipe□ | mm | 10-58 | 10-65 | 30~76 | 30~80 | 50~105 | 70~130 | ||

| TCT Super Hard Circular Saw Blade | mm | 250/285 X 2.0T | 315 X 2.25T | 360 X 2.6T | 360/380 X 2.6T | 460 X 2.7T | 560 X 3.0T | ||

| Pin Hole And Aperture | mm | 4xφ11 XPCD63X φ32 | 4xφ11 XPCD63X φ32 | 4xφ11 XPCD90X φ40 | 4xφ11 XPCD90X φ40 | 4xφ14 XPCD90X φ50 | 4xφ21 XPCD120X φ50 | ||

| Spindle Motor | kw | 7.5(4P) | 9.5(4P) | 11(4P) | 15(4P) | 18.5(4P) | 30(4P) | ||

| Spindle Speed | rpm | 20-160 | 20-180 | 20-120 | 40-160 | 30-125 | 20-80 | ||

| Saw Head Feeding Moethod | AC servo motor+ball screw(pivot type feeding) | AC servo motor+ball screw(30° tilt feeding) | AC servo motor+ball screw(Pivot type feeding) | AC servo motor+ball screw(30° tilt feeding) | AC servo motor+ball screw(30° tilt feeding) | AC servo motor+ball screw(Horizontal feeding) | |||

| Main Clamping Vises | Hydraulic, one set of vertical and horizontal clamping | Hydraulic, one set of vertical and horizontal clamping | Hydraulic, one set of vertical and horizontal clamping | Hydraulic, one set of vertical and horizontal clamping | Hydraulic, one set of vertical and horizontal clamping | Hydraulic, one set of vertical and horizontal clamping | |||

| Chips Cleaning Device | Passive wire brush/power wire brush(optional) | Passive wire brush/power wire brush(optional) | Passive wire brush/power wire brush(optional) | Passive wire brush/power wire brush(optional) | Passive wire brush/power wire brush(optional) | Passive wire brush/power wire brush(optional) | |||

| Gear Backlash Compensation Device | Through shaft type magnetic powder brake | Through shaft type magnetic powder brake | Through shaft type magnetic powder brake | Through shaft type magnetic powder brake | Through shaft type magnetic powder brake | Through shaft type magnetic powder brake | |||

| Workpiece Feeding Drive Method | AC servo motor+ball screw | AC servo motor+ball screw | AC servo motor+ball screw | AC servo motor+ball screw | AC servo motor+ball screw | AC servo motor+ball screw | |||

| Feeding Vise Clamping Method | Hydraulic, horizontal clamping | Hydraulic, horizontal clamping | Hydraulic, horizontal clamping | Hydraulic, horizontal clamping | Hydraulic, horizontal clamping | Hydraulic, horizontal clamping | |||

| Workpiece Front End Removal Length | mm | 10~99(This function can be closed) | 10~99(This function can be closed) | 10~99(This function can be closed) | 10~99(This function can be closed) | 10~99(This function can be closed) | 10~99(This function can be closed) | ||

| Workpiece Final Remnant Length | mm | 65+α(α is smaller than the setup cutting length) | 70+α(α is smaller than the setup cutting length) | 75+α(α is smaller than the setup cutting length) | 100+α(α is smaller than the setup cutting length) | 100+α(α is smaller than the setup cutting length) | 130+α(α is smaller than the setup cutting length) | ||

| Single Feeding Length Range | mm | 6-780 | 6-800 | 10-680 | 10-800 | 10-800 | 10-650 | ||

| Automatic Workpiece Feeding Length To Be Loaded | mm | 3000-6000 | 3000-6000 | 3000-6000 | 3000-6000 | 3000-6000 | 3000-6000 | ||

| Automatic Workpiece Feeding Method | Pr-arranged type|hydraulic lift | Pr-arranged type|hydraulic lift | Pr-arranged type|hydraulic lift | Pr-arranged type|hydraulic lift | Pr-arranged type|hydraulic lift | Pr-arranged type|hydraulic lift | |||

| Hydraulic Motor | kw | 2.25(4P) | 2.25(4P) | 2.25(4P) | 2.25(4P) | 3.75(4P) | 5.5(4P) | ||

| Rated Pressure Of Hydraulic System | MPa | 4.5~7 | 4.5~7 | 4.5~7 | 4.5~7 | 4.5~7 | 4.5~7 | ||

| Hydraulic Tank Capacity | L | 90 | 120 | 110 | 150 | 150 | 150 | ||

| Cooling Fluid Device Motor | kw | 0.19(2P) | 0.19(2P) | 0.19(2P) | 0.19(2P) | 0.19(2P) | 0.19(2P) | ||

| Weight(Host Machine+Roller Table) | kg | 3000 | 4500 | 3900 | 5400 | 5600 | 12400 | ||

| Machine Size(LXW) | mm | 7100X2200 | 6910X3000 | 6500X2760 | 7234X3339 | 7300X3600 | 7416X3788 | ||

Product Introduction

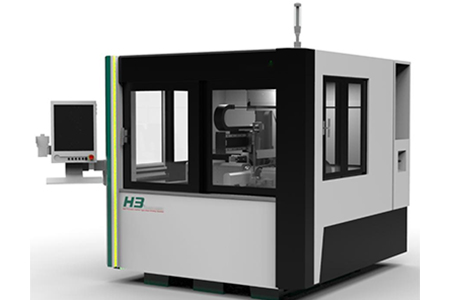

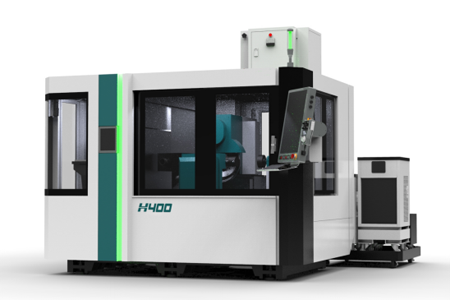

High speed metal circular saw machine series

- Servo feed and feed system cutting accuracy;

- 5 times cutting speed of traditional sawing machine;

- The main clamp adopts the international popular three point type clamping, and the clamping is firm and reliable;

- Active tilting feeding can avoid material surface damage and improve feed accuracy;

- High precision, high precision spindle gear box with backlash elimination mechanism, so that the stability of the feed, greatly improve the tool life;

- One button start, conversational touch input, simple and fast operation.

Accessories

Standard Equipment

1. Saw blade swing anti-vibration device : Aluminum carbide parallel block

2. Out-feeding workpiece separating device : Pneumatic|Reciprocating

3. Automatic centralized lubrication system : Regular and quantitative compulsory grease supply

4. Tool micro lubrication system : Quasi-dry intermittent lubrication

5. Chip conveyor : Chain plate type I continuous or intermittent operation

6: Working light : LED|Waterproof and dustproof

Optional Equipments

Hydrualic loading rack

TCT saw blades

Advantages:

Continuous Innovation

High-tech enterprises, with a number of mature technical teams, annual research and development funds of 2 million, annual research and development of more than 12 new products, 20 national patent technology, continuous innovation.

6S Workshop Standard

36000 ㎡ workshop, 6S workshop standard, workshop through the ISO9001 quality system certification, with complete production equipment, products leave the factory after raw material inspection, process inspection, finished product inspection, products in line with GB and CE standard certification.

Self-built the Factory

Self-built the factory, through the whole industry chain, perfect casting factory, sheet metal factory, CNC machining center, cutting center, processing plant, accessories, the whole process of independent design and development, further reduce the cost, guarantee quality and improve the cost performance.

Our Parnter