Technical Data

| Technical Specification | CL-300NC |

| Round bar ● | 150 ~ 300 mm |

| Square bar ▓ | 150 ~ 220 mm |

| Round tube ○ | 150 ~ 300mm Wall thickness ≥ pipe outer diameter * 10% (∅150*10%=15) |

| Square tube □ | 150 ~ 220mm |

| Machine head spindle | |

| Applicable to TCT tungsten carbide circular saw blade | Ø960 x 4.2 mm |

| Saw blade rotation number | 20 ~ 50 rpm / Variable speed |

| Saw blade debris remover | Round wire brush |

| motor | |

| Spindle drive motor | 55kw |

| AC servo motor_feed mechanism | 7.0kw |

| AC servo motor_delivery mechanism | 5.0kw |

| Hydraulic drive motor | 10HP / 4p |

| Hydraulic device | |

| Hydraulic drive pressure | 85 kg/cm2(8.5 MP a) |

| Hydraulic tank capacity | 150 liters |

| Air pressure device | |

| Working air pressure | 4 ~ 6 kg/cm2(55 ~ 85 psi) |

| Fixed-size feeding (GFC) mechanism | |

| End cutting length | 10~99mm |

| Residual length | 130+a (α is the length of a workpiece) |

| Feeding length | 800mm (single) |

| other | |

| Weight / main machine + rack | 15500KGS |

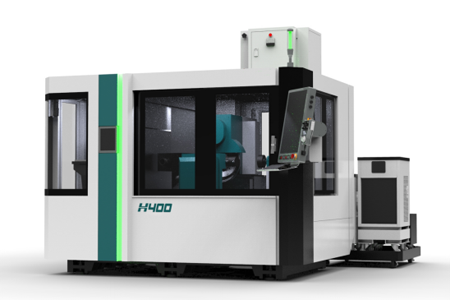

Product Introduction

This equipment is mainly composed of machine tool bed, power head, feeding system, feeding device, clamping device, material dividing device, hydraulic system, electrical system, tool lubrication system, automatic lubrication system, automatic chip removal system, automatic loading system, etc.

1.Machine tool body

The bed is a key component of machine tool equipment. It is made of high-strength HT350 and is integrally cast. It has the characteristics of high strength, good rigidity, impact resistance, small deformation, and outstanding shock absorption performance. A well-structured bed can significantly improve the overall rigidity of the machine tool as well as the sawing stability and reliability.

2.Feed system

The servo motor + high-precision ball screw drives the power head to feed horizontally and forcefully, and the clamped workpiece can be cut off quickly and with high precision. This method is the current internationally advanced machine tool feeding sawing method, which can more effectively ensure the stability, reliability and continuity of the sawing process.

3.Power head

The power head is mainly composed of gearbox, pulley, spindle motor, magnetic powder brake, etc. The gearbox is cast with high-strength ductile iron QT450-10, and the high-precision ground forming gear adopts hardened bevel gear multi-stage transmission design, with high precision and smooth transmission. The magnetic powder brake is combined with the uniquely designed gear backlash elimination mechanism to achieve one-way zero-gap transmission, which greatly improves the service life of the tool. The gearbox bearings are all high-precision bearings of brands such as NSK, IKO, and SKF. The gearbox runs smoothly, has high transmission efficiency, high rigidity and high precision.

Using the spindle servo motor to drive the gearbox can achieve stepless speed change of the spindle, and the heat loss of large-scale speed regulation is small, and it can reach the ability of 30 minutes of continuous overload without damaging the motor.

The power head is guided by high-rigidity and high-precision roller-type linear guides, which can ensure feed accuracy and rigidity, and is a strong guarantee for cutting accuracy and life.

4.Clamping device (main clamp)

The main clamp is fixed on the bed and consists of a set of horizontal clamps and a set of vertical clamps installed on the clamp seat. It can provide horizontal and vertical clamping force to the workpiece during the cutting process. The clamping power is provided by the hydraulic cylinder, and the two sets of clamps can act independently.

5.Feeding mechanism

The feeding mechanism adopts a large-diameter, high-load double guide rod structure, and uses a high-power AC servo motor to directly drive the grinding-grade ball screw to perform linear reciprocating motion, with good rigidity and high precision. The clamping mechanism is powered by a hydraulic cylinder, with sufficient clamping force and high clamping precision. The clamp of the feeding mechanism can swing up and down during the forward and backward feeding process, which can prevent the material from scratching and interfering with the clamping device, extend the service life of the clamp, and improve the cutting accuracy.

6.Hydraulic system

The hydraulic system adopts an external independent structure for easy maintenance. It adopts integrated installation of superimposed valves, which is compact, safe and reliable.

Continuous Innovation

High-tech enterprises, with a number of mature technical teams, annual research and development funds of 2 million, annual research and development of more than 12 new products, 20 national patent technology, continuous innovation.

6S Workshop Standard

36000 ㎡ workshop, 6S workshop standard, workshop through the ISO9001 quality system certification, with complete production equipment, products leave the factory after raw material inspection, process inspection, finished product inspection, products in line with GB and CE standard certification.

Self-built the Factory

Self-built the factory, through the whole industry chain, perfect casting factory, sheet metal factory, CNC machining center, cutting center, processing plant, accessories, the whole process of independent design and development, further reduce the cost, guarantee quality and improve the cost performance.

Our Parnter