Technical Data

| Technical Specification | Machine Model: CL-260G |

| Cut Circular @90° | 227mm(9”) |

| Cut Rectangular @90° | 260x200mm (10”x7.9”) |

| Cut Circular @60° | 90mm(3.5”) |

| Cut Rectangular @60° | 85x85mm (3.5″x3.5″) |

| Cut Circular @45° | 150mm(6”) |

| Cut Rectangular @45° | 150x125mm (6”x5”) |

| Blade speed @50Hz | 2P,72MPM 236FPM |

| 4P,36MPM 118FPM | |

| Blade speed @60Hz | 2P,86MPM 283FPM |

| 4P,43MPM 141FPM | |

| Blade size | 20X0.9X2445mm |

| Motor power | 0.75/1.1kw |

| 1/1.5HP(3PH) | |

| Drive | Gear |

| Packing size | 145x72x102 cm |

| N.W./G.W. | 220/275kg |

Product Introduction

1. 9″ round and 10″x7.9″ rectangular cutting capacity at 90°

2. Cast iron saw frame max. miter 60°

3. Hydraulic descent

4. Quick action lock/release lever for swivel head

5. Coolant system as standard

6. Control panel mounted for easy access

7. Adjustable length stop for repetition cutting

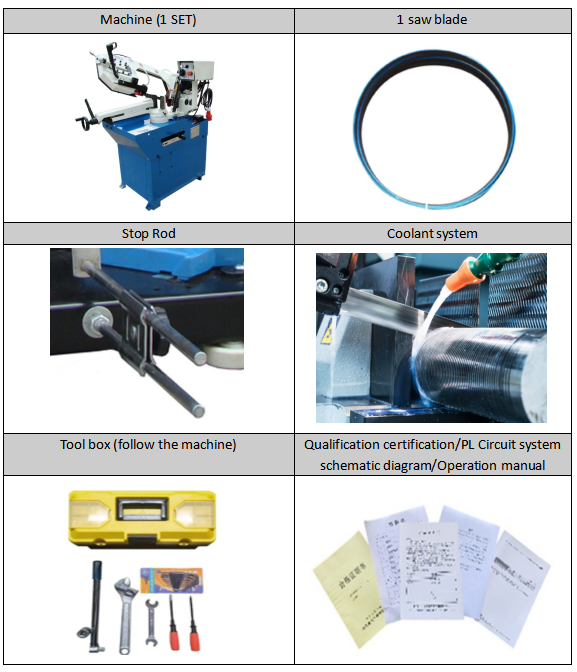

Accessories

Advantages:

Continuous Innovation

High-tech enterprises, with a number of mature technical teams, annual research and development funds of 2 million, annual research and development of more than 12 new products, 20 national patent technology, continuous innovation.

6S Workshop Standard

36000 ㎡ workshop, 6S workshop standard, workshop through the ISO9001 quality system certification, with complete production equipment, products leave the factory after raw material inspection, process inspection, finished product inspection, products in line with GB and CE standard certification.

Self-built the Factory

Self-built the factory, through the whole industry chain, perfect casting factory, sheet metal factory, CNC machining center, cutting center, processing plant, accessories, the whole process of independent design and development, further reduce the cost, guarantee quality and improve the cost performance.

Our Parnter