Technical Data

| Items | Unit | Machine Model:MK7136 | Machine Model:MH7136 |

| Table size | mm | 1250×360 | 1250×360 |

| X axis travel | mm | 900 | 900 |

| Y axis travel | mm | 400 | 400 |

| Z axis travel | mm | 500 | 500 |

| Max. worktable load | kg | 460 | 460 |

| T slot(number-width-pitch) | 3-18×80 | 3-18×80 | |

| Max. spindle speed | rpm | 8000 | 8000 |

| Spindle taper | mm | BT40 | BT40 |

| Main motor power | kw | 5.5 | 5.5 |

| X/Y/Z rapid traverse speed | m/min | 10/10/10 | 10/10/10 |

| Cutting feed speed | mm/min | 1-6000 | 1-6000 |

| Guide rail type | Hard rail | Hard rail | |

| Distance from spindle axis to column surface | mm | 460 | 460 |

| Distance between spindle nose and worktable surface | mm | 100-600 | 100-600 |

| Positioning accuracy | mm | ±0.04 | ±0.04 |

| Repeat positioning accuracy | mm | ±0.02 | ±0.02 |

| Tool magazine | – | 16 Arm-less/(Optional: Arm 16 ) | |

| Max. tool diameter | mm | – | Ø90 |

| Max.tool weight | kg | – | 8 |

| Machine weight | kg | 2600 | 2800 |

| Overall dimension | mm | 2380x1900x2350 | 3000x2400x2500 |

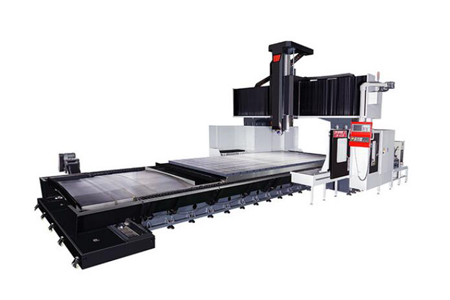

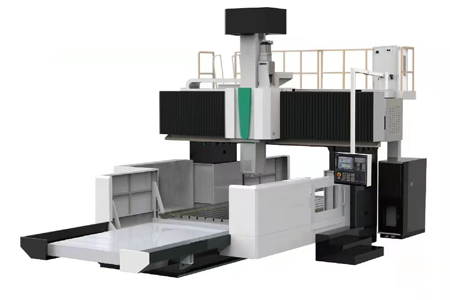

Product introduction

MK7136 MH7136 CNC Milling Machine suitable for drilling , hole-expansion, reaming, bevel edge,and tapping, for surface milling, step plane ,slope ,and milling groove , for cutting and milling curve ,curve surface and cam.

Have the function of step-less speed and automatic speed change to gain large torque with low speed, suitable for processing thick cutting depth and larger-diameter hole.

The fuselage and main components are high strength cast iron, micro structure stability, ensure the stability of machine tool for long-term use.

Product Features:

- The fuselage and main components are high strength cast iron, microstructure stability, ensure the stability of machine tool for long-term use.

- The column at the bottom of A type bridge type structure, combined with the big box base, greatly reduce the vibration of machine on heavy cutting

- The pre tension precision ball screw drive

- The high speed, high precision, high rigidity spindle unit

- The design of oil-water separation

- The intermittent automatic lubrication

- Automatic scraping knife system

Applications:

The vertical machining center can be applied to many fields such as mechanical processing and mould manufacturing, canadapt from roughing to finishing processing requirements, has the characteristics of high precision, high efficiency, is widely used in aerospace, military industry, mould, automobile, internal combustion engines, textile machinery, chemical machinery processing, oil, electronics and other industries.

Advantages:

Continuous Innovation

High-tech enterprises, with a number of mature technical teams, annual research and development funds of 2 million, annual research and development of more than 12 new products, 20 national patent technology, continuous innovation.

6S Workshop Standard

36000 ㎡ workshop, 6S workshop standard, workshop through the ISO9001 quality system certification, with complete production equipment, products leave the factory after raw material inspection, process inspection, finished product inspection, products in line with GB and CE standard certification.

Self-built the Factory

Self-built the factory, through the whole industry chain, perfect casting factory, sheet metal factory, CNC machining center, cutting center, processing plant, accessories, the whole process of independent design and development, further reduce the cost, guarantee quality and improve the cost performance.

Our Parnter