Technical Data

| Items | Unit | Machine Model:M-VMC1060 | |

| Worktable | Table size (L*W) | mm | 1200×600 |

| T-slot (quantity x width x spacing) | mm | 5×18×100 | |

| Max. load capacity of the workbench | kg | 800 | |

| Processing range | X/Y/Z axis travel | mm | 1000/600/600 |

| Spindle end face to table distance | mm | 120-720 | |

| Distance from spindle center-line to column guide rail surface | mm | 650 | |

| Spindle | Spindle motor rated power | KW | 11/15 |

| Range of rotation | rpm | 8000 (10000/12000 direct Option) | |

| Taper hole model | BT40 | ||

| Pull stud specification | P40T-1-MAS403(45°) | ||

| Feed | X/Y/Z axis motor torque (stall) | Nm | 20/20/20 |

| X/Y/Z axis rapid movement speed | m/min | 36/36/24 | |

| X/Y/Z axis maximum feed speed | m/min | 10 | |

| Tool magazine | Automatic tool change method | disc manipulator | |

| Magazine capacity | ATC | 24 | |

| tool length | mm | 300 | |

| tool weight | Kg | 8 | |

| Max. tool diameter (full tool/neighbor empty tool) | mm | φ78/φ120 | |

| Tool to tool change time | s | About 1.55 | |

| Precision | Three-axis positioning accuracy | mm | 0.008 |

| Three-axis repeat positioning accuracy | mm | 0.007 | |

| other | Max. torque | Nm | 52.5/95.5 |

| Total power of machine tool | KVA | About 25 | |

| Machine weight | Kg | About 6800 | |

| Dimensions | mm | About 3200×2500×2800 | |

Product introduction

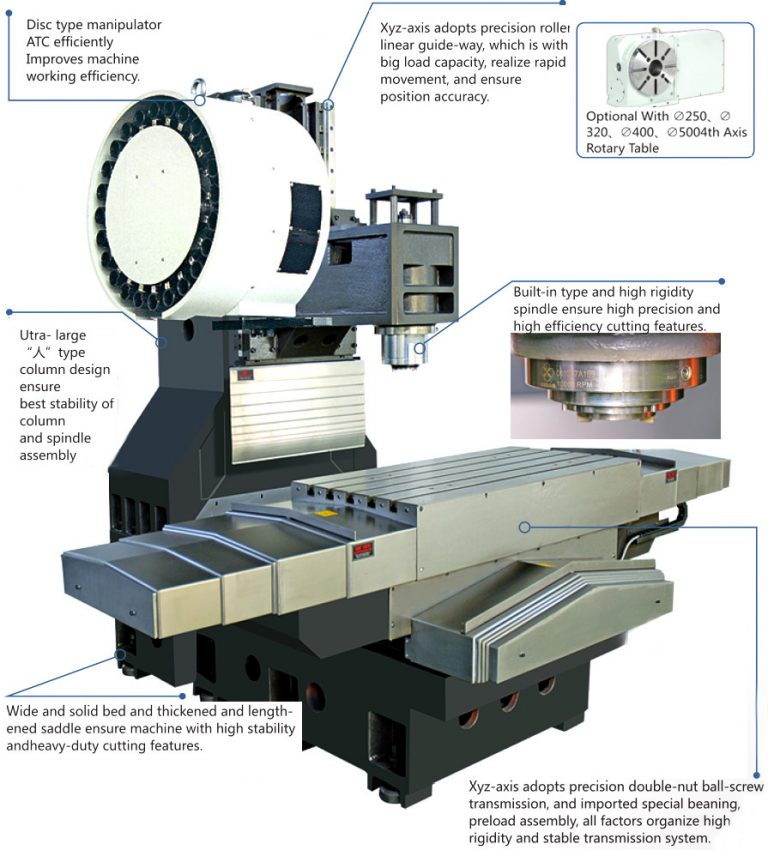

M-VMC1060 CNC milling machine machining take the advantages of traditional vertical linear rail machine tools, such as strong rigidity of the basic frame, symmetrical structure, and strong stability, and introduces the internationally advanced dynamic rigidity design concept and optimizes the design of moving parts. After one clamping, the parts can complete multi-sequence processing such as milling, boring, drilling, and tapping with high precision. The machine tool has high processing efficiency and good rapid response characteristics, and is suitable for the needs of various mechanical processing fields such as molds,automotive industry, and hardware and etc.

Quality Control Points to the VMC Machines

- High rigidity and long-term accuracy retention

The main large parts of the machine tool: the base, the worktable, the column, the saddle, and the head-stock are all made of high-quality resin sand, high-strength and high-quality cast iron, and have a perfect heat treatment process to eliminate residual stress. The machine has sufficient strength, rigidity and high stability.

The three-axis adopts roller linear guide, which has strong rigidity, fast response speed, high precision, and does not crawl at low speed.

The three-axis transmission adopts the grinding double-nut ball screw made in Taiwan, which is compact in structure, stable in motion and high in precision. The screw support adopts the screw support bearing imported from Japan, and the two ends are pr-stretched to eliminate the precision loss caused by thermal elongation. It forms a stable and high-rigidity mechanical transmission system.

The distance from the center of the main shaft to the guide rail surface is short, the turning moment is small, and the structure is rigid;

The high-rigidity Taiwan-made spindle is lubricated with grease, which can ensure constant and reliable lubrication of the spindle bearing, which is economical and environmentally friendly and realizes long-term maintenance-free;

- High precision and high dynamic response characteristics

The spindle adopts three-point support, two high-precision angular contact ball bearings are used at the front and rear ends, and one high-precision angular contact ball bearing is used in the middle, so that the spindle can obtain high rigidity and extremely high spindle rotation accuracy;

Roller linear guides are used for the three axes, with high precision, large load, low friction coefficient, optimized circle accuracy, accurate positioning, and high dynamic response characteristics;

- High efficiency

Spindle Standard speed up to 10000RPM, rapid movement up to 48/48/36 m/min, cutting feed rate up to 10 m/min; Customer can choose higher speed range as per the demand.

Equipped with an automatic tool changing device for manipulators, with the function of selecting the nearest tool, which is convenient for maintenance, and the tool exchange is fast and reliable;

- Protective cover

The protective cover made by a professional sheet metal manufacturer is used, and the base drainage is a large water pan structure, which prevents water leakage;

Equipped with air gun and water gun, the processing iron chips can be quickly collected into the chip box.

Advantages:

Continuous Innovation

High-tech enterprises, with a number of mature technical teams, annual research and development funds of 2 million, annual research and development of more than 12 new products, 20 national patent technology, continuous innovation.

6S Workshop Standard

36000 ㎡ workshop, 6S workshop standard, workshop through the ISO9001 quality system certification, with complete production equipment, products leave the factory after raw material inspection, process inspection, finished product inspection, products in line with GB and CE standard certification.

Self-built the Factory

Self-built the factory, through the whole industry chain, perfect casting factory, sheet metal factory, CNC machining center, cutting center, processing plant, accessories, the whole process of independent design and development, further reduce the cost, guarantee quality and improve the cost performance.

Our Parnter