Technical Data

| Items | Unit | Machine Model: VMC650 | VMC850 | VMC855 | VMC1060 | VMC1160 | VMC1260 | VMC1370 | VMC1380 | VMC1580 | VMC1680 | VMC1890 | |

| Table Size(length*width) | mm | 800×500 | 1000×500 | 1000×550 | 1200*600 | 1200*600 | 1200×600 | 1400X700 | 1400X800 | 1600×800 | 1700×800 | 2000×900 | |

| Max Loading Weight | kg | 400 | 500 | 500 | 800 | 800 | 800 | 1200 | 1300 | 1500 | 1500 | 2000 | |

| Number-width x distance | mm | 5-18×90 | 5-18×90 | 5-18×90 | 5-18×100 | 5-18×100 | 5-18×100 | 5-18×110 | 7-18×110 | 7-22*110 | 7-22*110 | 7-22*125 | |

| X/Y/Z Travel | mm | 650/500/500 | 800/500/500 | 800/550/550 | 1000/600/600 | 1000/600/600 | 1200/600/600 | 1300/700/700 | 1300/800/700 | 1500/800/700 | 1600/800/700 | 1800/900/800 | |

| Max .Distance From spindle nose to Table Surface | mm | 120-620 | 150-650 | 120-670 | 120-720 | 120-720 | 120-720 | 100-800/160-760 | 185-885 | 150-850 | 155-855 | 150-950 | |

| Spindle center to Z axis guide surface | mm | 550 | 570 | 595 | 650 | 650 | 650 | 750 | 850 | 855 | 855 | 950 | |

| Spindle motor power | kW | 7.5/11 | 7.5/11 | 7.5/11 | 11月15日 | 11月15日 | 11月15日 | 11/15/15/18.5 | 15/18.5 | 15/18.5 | 15/18.5 | 15/18.5 | |

| Max. Spindle Speed | rpm | 10000 | 10000 | 8000 | 8000 | 8000 | 8000 | 8000/6000 | 8000/6000 | 6000 | 6000 | 6000 | |

| Spindle Taper | BT40 | BT40 | BT40 | BT40 | BT40 | BT40 | BT40/BT50 | BT50 | BT50 | BT50 | BT50 | ||

| 3 axis rapid speed | m/min | 48/48/48 | 48/48/36 | 48/48/36 | 36/36/36 . | 36/36/36 . | 36/36/36 | 24/24/24 | 20/20/20 | 20/20/20 | 20/20/20 | 18/18/15 | |

| Max cutting speed | m/min | 10 | 10 | 0 | 10 | 10 | 10 | 10 | 10 | 10 | 10 | 10 | |

| Pull stud | MAS403 BT40-45° | MAS403 BT40-45° | MAS403 BT40-45° | MAS403 BT40-45° | MAS403 BT40-45° | MAS403 BT40-45° | MAS403 BT40-45° | MAS403 BT50-45° | MAS403 BT50-45° | MAS403 BT50-45 | MAS403 BT50-45 | ||

| ATC capacity | BT40-24T | BT40-24T | BT40-24T | BT40-24T | BT40-24T | BT40-24T | BT40/50-24T | BT50-24T | BT50-24T | arm type BT50-24T | arm type BT50-24T | ||

| Max. Diameter of tool length | mm | Φ85×350 | Φ85×350 | Φ85×350 | Φ85×350 | Φ85×350 | Φ85×350 | Φ85/125*350 | Φ125×300 | Φ125*300 | 125×300 | 125×300 | |

| Positioning Accuracy | mm | ±0.004 | ±0.004 | 0.004 | +0.004. | 0.004 | 0.006 | 0.006 | 0.006 | 0.006 | 0.006 | 0.006 | |

| Repeatability Accuracy | mm | ±0.003 | ±0.003 | 0.003 | 0.003 | 0.003 | +0,004 | +0,004 | +0,004 | +0,004 | 0.004 | 0.004 | |

| CNC system | FANUC/SIEMENS/MITSUBISHI CNC OPERATION SYSTEM | ||||||||||||

| Machine Size (L*W*H) | mm | 2100x2600x2650 | 2700x2500x2650 | 2700x2500x2650 | 3200x2550x2700 | 3200x2550x2700 | 3200x2550x2700 | 3500x2700x2800 | 4000x2700x2800 | 4100x2700x2800 | 4150×3370×2900 | 4300×3450×2900 | |

| Machine Weight | Kg | 4900 | 5300 | 5800 | 6800 | 7000 | 7500 | 10800 | 13800 | 14300 | 14800 | 15800 | |

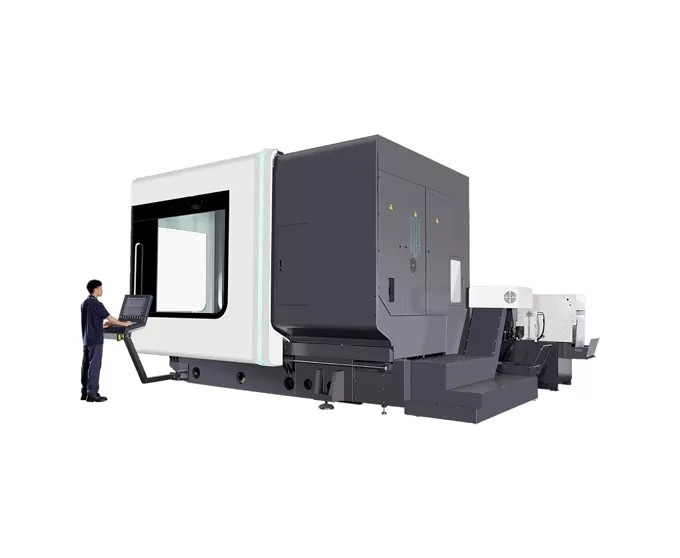

Product introduction

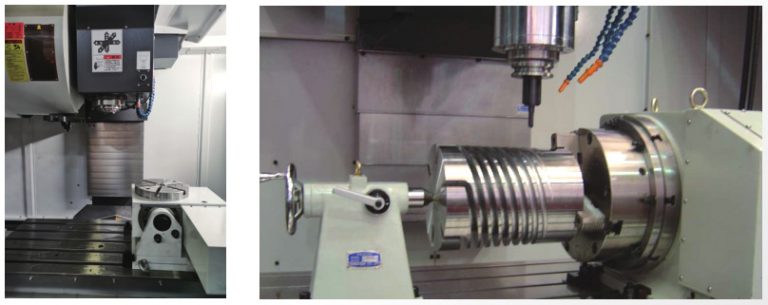

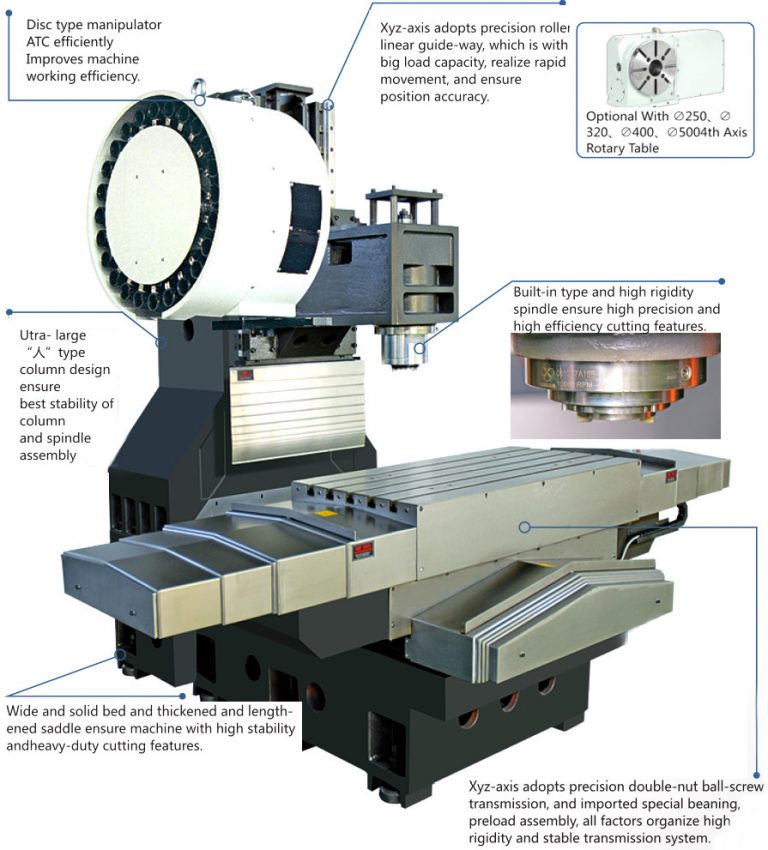

The machine tool adopts a new generation of vertical machining center with high precision, high speed and high rigidity developed by 3D computer-aided design and finite element analysis. The guide rail adopts three-line rail (or two-line one-hard) guide rails, and the maximum rapid speed can reach 48m / min, spindle speed 6000 to 15000 rpm optional positioning accuracy <4μm, repeated positioning <3μm; suitable for various mechanical processing fields such as mold, military industry, hardware, auto parts and so on.

M-VMC Series Vertical Machine Center inherits the advantages of strong rigidity, symmetrical struc-ture and strong stability of the foundation frame of the traditional vertical CNC milling machine,introduces the international advanced dynamic rigidity design concept, and optimizes the design of the moving parts.

Machine torque, quick response characteristics, suitable for automotive, mold, aerospace, military, hardware and other mechanical processing needs.

Machine torque, quick response characteristics, suitable for automotive, mold, aerospace, military, hardware and other mechanical processing needs.High rigidity,High reliability,High degree of mechatronics,The operation is simple,The over-all shape is beautiful and generous,Especially suitable for small batch or single processing.

Accessories:

| Standard Equipment | Optional Equipment |

| The back row chip full cover sheet metal without the chip | Front row chip full cover sheet metal belt chip remover |

| Drawer type water tank and chip box | Central outlet function of spindle |

| Backward impact chip washing device | 3 axis linear scale |

| Full-function operation panel and handwheel | Function of the fourth axis |

| ATC | Spindle oil cooling function |

| Belt drive spindle | Straight connection drive spindle |

| Sprinkler cooling system at the spindle side | Oil-water separation device |

| Air cooling system at spindle side | Workpiece and tool measuring device |

| Heat exchange device of electric cabinet | Door open switch |

| Work area cleaning water gun, air gun | High speed and high precision functions |

| Working light and alarm light | Column elevation (bridge type or height block) |

Advantages:

Continuous Innovation

High-tech enterprises, with a number of mature technical teams, annual research and development funds of 2 million, annual research and development of more than 12 new products, 20 national patent technology, continuous innovation.

6S Workshop Standard

36000 ㎡ workshop, 6S workshop standard, workshop through the ISO9001 quality system certification, with complete production equipment, products leave the factory after raw material inspection, process inspection, finished product inspection, products in line with GB and CE standard certification.

Self-built the Factory

Self-built the factory, through the whole industry chain, perfect casting factory, sheet metal factory, CNC machining center, cutting center, processing plant, accessories, the whole process of independent design and development, further reduce the cost, guarantee quality and improve the cost performance.

Our Parnter