Technical Data

| Items | Unit | Machine Model: HMC500APC | HMC630APC | HMC630SAPC | HMC800APC | |

| Processingcapacity | Column travel ( X axis ) | mm | 800 | 1050 | 1050 | 1400 |

| Spindle travel (Y axis ) | mm | 750 | 900 | 750 | 950 | |

| Table travel ( Z axis ) | mm | 850 | 1000 | 900 | 1370 | |

| Distance from pallet surface to spindle center | mm | 100-850 | 100-1000 | 130-1030 | 100-1050 | |

| Distance from pallet center to spindle gauge plane | mm | 100-950 | 140-1160 | 0-750 | 150-1420 | |

| Processingcapacity | X axis rapid speed | mm/min | 48000 | 36000 | 20000 | 36000 |

| Y axis rapid speed | mm/min | 48000 | 36000 | 20000 | 36000 | |

| Z axis rapid speed | mm/min | 48000 | 36000 | 20000 | 36000 | |

| X/Y/Z axis cutting speed | mm/min | 20000 | 20000 | 10000 | 20000 | |

| Pallet | Table size | mm | 500*500 | 630×630 | 630x 700 | 800x 800 |

| Table no. | 2 | 2 | 2 | 2 | ||

| Table dividing type | 。 | 1( 0.001 ) | 1( 0.001 ) | 1( 0.001 ) | 1( 0.001 ) | |

| Table max loading weight | kg | 500 | 1200 | 950 | 2000 | |

| Tale T slot sie(N0,Width Distance) | mm | 14x5x 100 | 18x5x125 | 5x18x125 | 22x5x 160 | |

| Change time | sec | 15 | 16 | 20 | 18 | |

| Pallet | Spindle taper | ISO50 | ISO50 | ISO50 | ISO50 | |

| Spindle motor | kW | 11/15 | 15/18.5 | 15/18.5 | 18.5/22 | |

| Spindle speed | rpm | 20-6000 | 20-6000 | 20-6000 | 20-6000 | |

| Spindle max torquel(continuous/30min) | Nm | 140/191 | 249/307 | 249/307 | 520/619 | |

| Pull-stud | MAS403 P50T-1 | MAS403 P50T-1 | MAS403 P50T-1 | MAS403 P50T-1 | ||

| Accuracy | X/ Y/Z positioning accuracy | mm | 0.01 | 0.01 | 0.018 | 0.01 |

| X/Y/ Z repeated accuracy | mm | 0.006 | 0.008 | 0.01 | 0.008 | |

| B positioning accuracy | “ | ±4(±15) | ±4(+15) | ±15 | ±4(±15) | |

| B repeated accuracy | “ | ±1(±6) | ±1(±6) | ±4 | ±1(±6) | |

| ATC | Capacity | T | 40/60 | 40/60 | 32/40 | 40/60 |

| Max tool diameter | mm | Φ125/250 | Φ125/250 | Φ125/250 | Φ125/250 | |

| Max tool length | mm | 400 | 400 | 300 | 400 | |

| Max tool weight | kg | 25 | 25 | 18 | 25 | |

| Change time | sec | 3.5 | 3.5 | 4.5 | 3.5 | |

| Others | Total power | kw | 40 | 50 | 45 | 50 |

| Machine overall size(L*W*H) | mm | 6700x4200x3350 | 7600x4200x3650 | 6500x4100x3450 | 8400x 5000×3850 | |

| Machine weight | kg | 16000 | 22000 | 16000 | 26000 | |

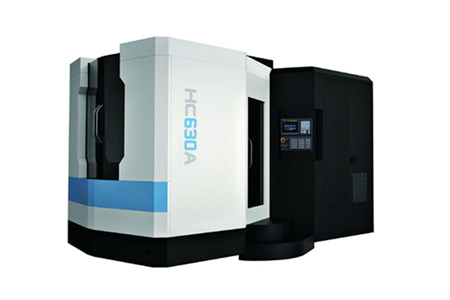

Product introduction

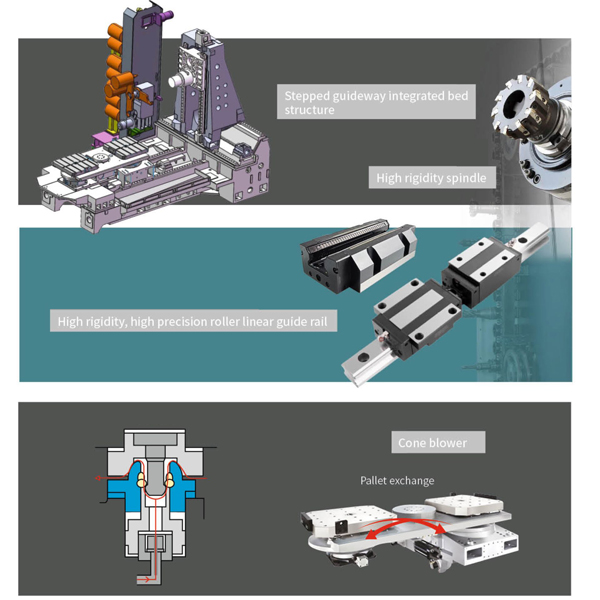

HMC series is a horizontal machining center designed and developed by the company on the basis of absorbing advanced machine tool design concepts at home and abroad.

This machine adopts T type bed structure design, adopts high rigid roller linear guideway, the guide way span is large, the machine overall rigidity is good, the bearing capacity is strong; Equipped with a rotary double exchange table, the exchange time is short, the table exchange positioning accuracy is high; Machine in processing parts at the same time can carry out the next spare parts of the damping, saving the damping time, improve the work efficiency;

The machine is especially suitable for batch processing of large and medium-sized box polyhedron parts. It can complete milling, boring, drilling, tapping and other processes in one time,greatly improving the processing eficiency.

Accessories:

| Standard Equipment | Optional Equipment |

| 24 tool ATC | 32 Arm chian type ATC |

| Spindle air curtain dust control system | 40 Arm chian type ATC |

| Workpiece cooling system | Central outlet of spindle (equipped with high pressure cooling device) |

| Equal division CNC rotary table | ZF gearbox drive |

| Automatic lubrication system | Spindle oil cooling device |

| Spiral chip removal device | Arbitrary indexing CNC rotary table |

| Chain-plate type chip lifter | Scraper lift chip remover |

| Integral shield | 3 axis linear scale |

| The toolkit | Tool detection device |

| Anchor bolt and pad iron | Workpiece detection device |

| Door opening protection (door protection) | |

| Portable chip air gun | |

| Machine cleaning water tank | |

| Simple oil and water separator |

Advantages:

Continuous Innovation

High-tech enterprises, with a number of mature technical teams, annual research and development funds of 2 million, annual research and development of more than 12 new products, 20 national patent technology, continuous innovation.

6S Workshop Standard

36000 ㎡ workshop, 6S workshop standard, workshop through the ISO9001 quality system certification, with complete production equipment, products leave the factory after raw material inspection, process inspection, finished product inspection, products in line with GB and CE standard certification.

Self-built the Factory

Self-built the factory, through the whole industry chain, perfect casting factory, sheet metal factory, CNC machining center, cutting center, processing plant, accessories, the whole process of independent design and development, further reduce the cost, guarantee quality and improve the cost performance.

Our Parnter