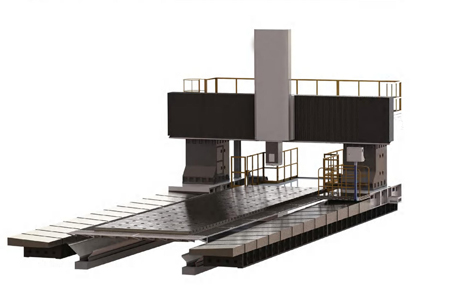

Technical Data

| Items | GMC2642x100 | GMC2642x120 | GMC2642x140 | GMC2642x160 | GMC2642x180 | GMC2642x200 |

| Processing Range | ||||||

| Gantry effective width (mm) | 4200(5000) | |||||

| X travel (mm) | 10800 | 12800 | 14800 | 16800 | 18800 | 20800 |

| Y travel (mm) | 4600(5000) | |||||

| Z travel (mm) | 1250/1500 | |||||

| Spindle nose to table face (mm) | 250~1500/1750 | |||||

| Table | ||||||

| Table size (WxL) (mm) | 3000×10000 | 3000×12000 | 3000×14000 | 3000×16000 | 3000×18000 | 3000×20000 |

| (4000×10000) | (4000×12000) | (4000×14000) | (4000×16000) | (4000×18000) | (4000×20000) | |

| Max loading (t) | 10 | |||||

| Table T-slot(no -Size x Distance) | 36×250 | |||||

| Spindle | ||||||

| Ram Form and dimension (mm) | Square Ram | |||||

| 450×450 | ||||||

| Maximum spindle speed (rpm) | 3500 | |||||

| Spindle power (kw) | 22/26(30/37) | |||||

| Spindle Drive Form | Direct Connect +ZF double Speed Gear Box | |||||

| Spindle taper | BT5O | |||||

| ATC(options) | ||||||

| Tool capacity (T) | 24/32/40/60 | |||||

| Maximum tool diameter (mm) | Φ125/230 | |||||

| Maximum tool length (mm) | 300 | |||||

| Maximum tool weight (mm) | 15 | |||||

| Others | ||||||

| Total power supply capaty(KVA) | 100 | |||||

| Machine weight(T) | 125 (140) | 140 (160) | 155 (180) | 170 (200) | 185 (220) | 200 (240) |

| Machine size(mm) | 17000x8000x6800 | 19000x8000x6800 | 21000x8000x6800 | 23000x8000x6800 | 25000x8000x6800 | 27000x8000x6800 |

| (17000x9000x6800) | (19000x9000x6800) | (21000x9000x6800) | (23000x9000x6800) | (25000x9000x6800) | (27000x9000x6800) | |

| CNC Control System | SIEMENS 828D | SIEMENS 828D | SIEMENS 828D | FANUC Oi-MF | SIEMENS 828D | SIEMENS 828D |

| FANUC Oi-MF | FANUC Oi-MF | FANUC Oi-MF | FANUC Oi-MF | FANUC Oi-MF | FANUC Oi-MF | |

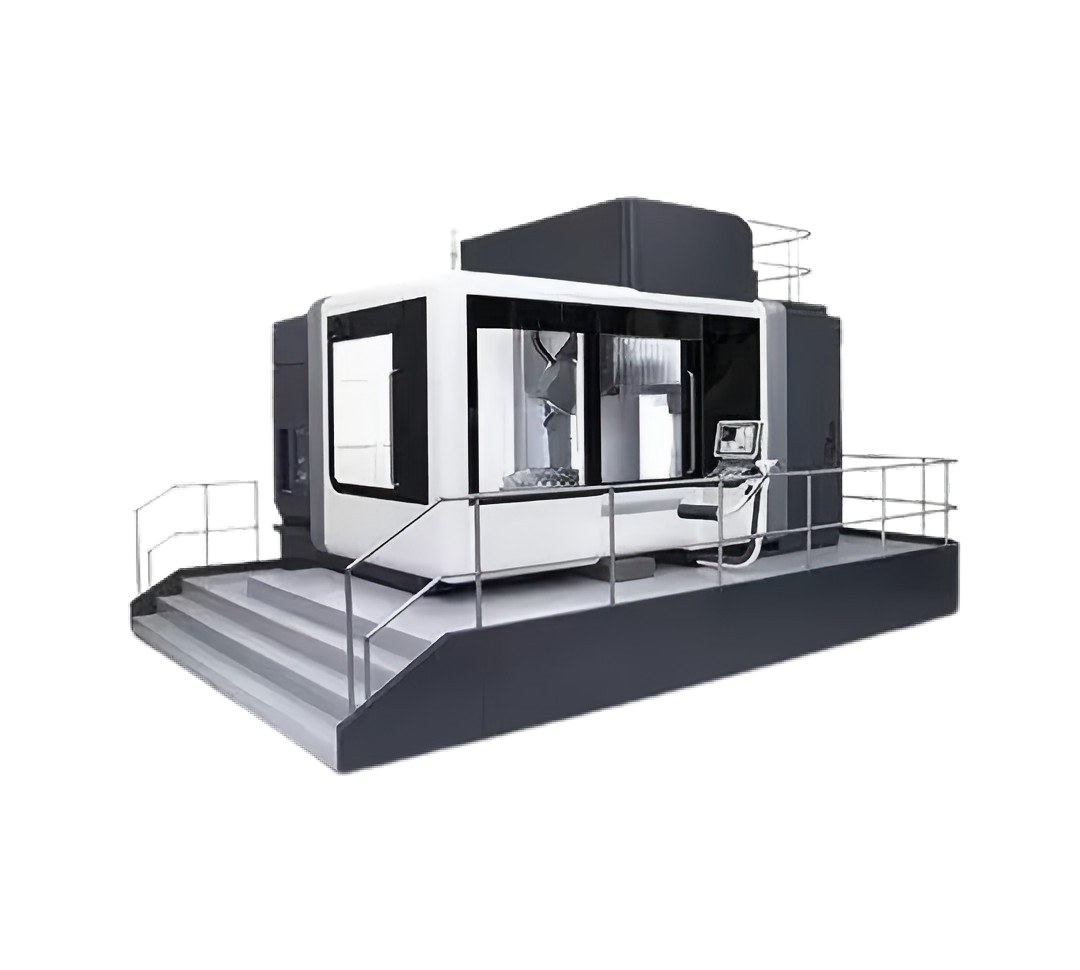

Product Features:

- Single side double pinion and rack electronic backlash elimination, gantry moving synchronization accuracy is high.

- Spindle speed change adopts ZF gearbox and self-made gearbox combination, improve the output torque of machine tool spindle, suitable for heavy cutting.

- Square pillow section 450mm x 450mm/500mm x 500mm, adopts double servo drive, stroke 1500mm/2000mm, good rigidity, with heavy load spindle unit, can be heavy cutting.

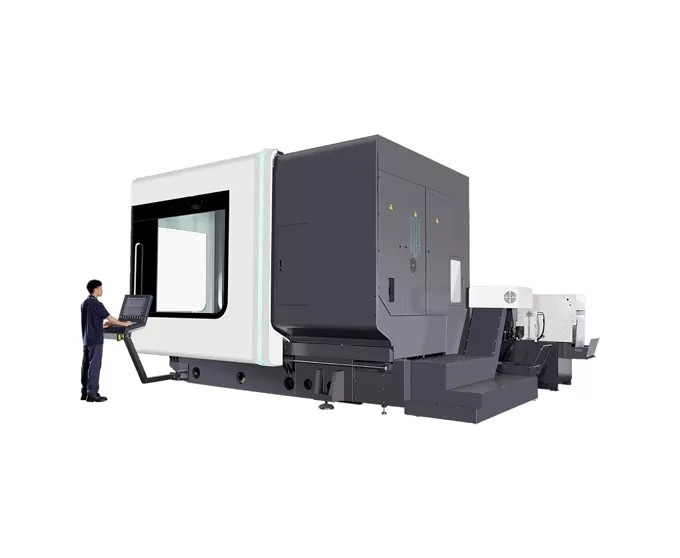

Advantages:

Continuous Innovation

High-tech enterprises, with a number of mature technical teams, annual research and development funds of 2 million, annual research and development of more than 12 new products, 20 national patent technology, continuous innovation.

6S Workshop Standard

36000 ㎡ workshop, 6S workshop standard, workshop through the ISO9001 quality system certification, with complete production equipment, products leave the factory after raw material inspection, process inspection, finished product inspection, products in line with GB and CE standard certification.

Self-built the Factory

Self-built the factory, through the whole industry chain, perfect casting factory, sheet metal factory, CNC machining center, cutting center, processing plant, accessories, the whole process of independent design and development, further reduce the cost, guarantee quality and improve the cost performance.

Our Parnter