Technical Data

| Items | Unit | GMC2132×40 | GMC2132×60 | GMC2132×80 | GMC2137×60 | GMC2137×80 |

| X axis stroke | mm | 4200 | 6200 | 8200 | 6500 | 8500 |

| Y axis stroke | mm | 3800 | 3800 | 3800 | 4300 | 4300 |

| Z axis stroke | mm | 1250 | 1250 | 1250 | 1250 | 1250 |

| W-axis travel (5×250 multi-point positioning/continuous) | mm | 1250 | 1250 | 1250 | 1250/1600 | 1250/1600 |

| Effective width of gantry | mm | 3200 | 3200 | 3200 | 3700 | 3700 |

| Maximum distance from table to spindle endface | mm | 2450 | 2450 | 2450 | 2450/2750 | 2450/2750 |

| Table size | mm | 2500×4000 | 2500×6000 | 2500×8000 | 3000×6000 | 3000×8000 |

| Max. loading weight | t | 18 | 24 | 30 | 28 | 35 |

| T-slot (W x spacing x No.) | 28×200×12 | 28×200×12 | 28×200×12 | 28×200×14 | 28×200×14 | |

| Max. cutting speed X/Y/Z | m/min | 6/6/6 | 6/6/6 | 6/6/6 | 6/6/6 | 6/6/6 |

| Rapid movement speed X/Y/Z | m/min | 10/10/10 | 10/10/10 | 10/10/10 | 10/10/10 | 10/10/10 |

| Max. spindle speed | rpm | 4000 | 4000 | 4000 | 4000 | 4000 |

| Spindle power (continuous/30min) | kW | 22/26 | 22/26 | 22/26 | 30/37 | 30/37 |

| Spindle torque | N.m | 770/910 | 770/910 | 770/910 | 1050/1260 | 1050/1260 |

| Spindle taper | mm | BT50 | BT50 | BT50 | BT50 | BT50 |

| Ram section | mm | 450×450 | 450×450 | 450×450 | 450×450 | 450×450 |

| ATC capacity | 24/32/40/60 | 24/32/40/60 | 24/32/40/60 | 24/32/40/60 | 24/32/40/60 | |

| Max. tool diameter (full/empty) | mm | Φ125/Φ250 | Φ125/Φ250 | Φ125/Φ250 | Φ125/Φ250 | Φ125/Φ250 |

| Max. tool length | mm | 400 | 400 | 400 | 400 | 400 |

| Max. tool weight | kg | 25 | 25 | 25 | 25 | 25 |

| Accuracy (implementation standard GB/T19362.1-2003) | ||||||

| Positioning accuracy X/Y/Z | mm | 0.025/0.030/0.020 | 0.028/0.030/0.020 | 0.03/0.030/0.020 | 0.028/0.035/0.020 | 0.03/0.035/0.020 |

| Repeat positioning accuracy X/Y/Z | mm | 0.018/0.020/0.015 | 0.018/0.020/0.015 | 0.018/0.020/0.015 | 0.018/0.020/0.015 | 0.018/0.020/0.015 |

| others | ||||||

| Total power capacity | KVA | 90 | 90 | 90 | 100 | 100 |

| Machine weight | t | 72 | 80 | 90 | 100 | 112 |

| Machine dimensions (L×W×H) | cm | 1300×880×800 | 1700×880×800 | 2100×880×800 | 1700×950×820 | 2100×950×820 |

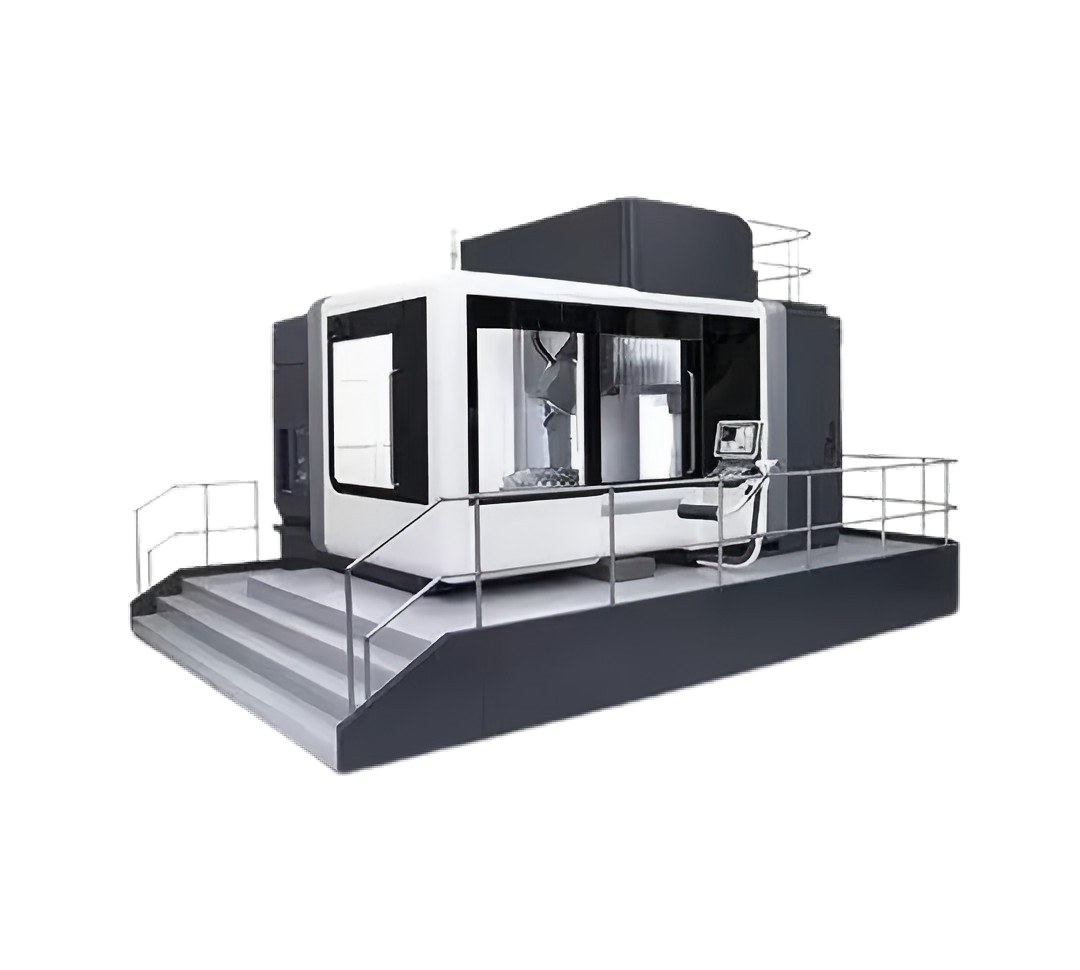

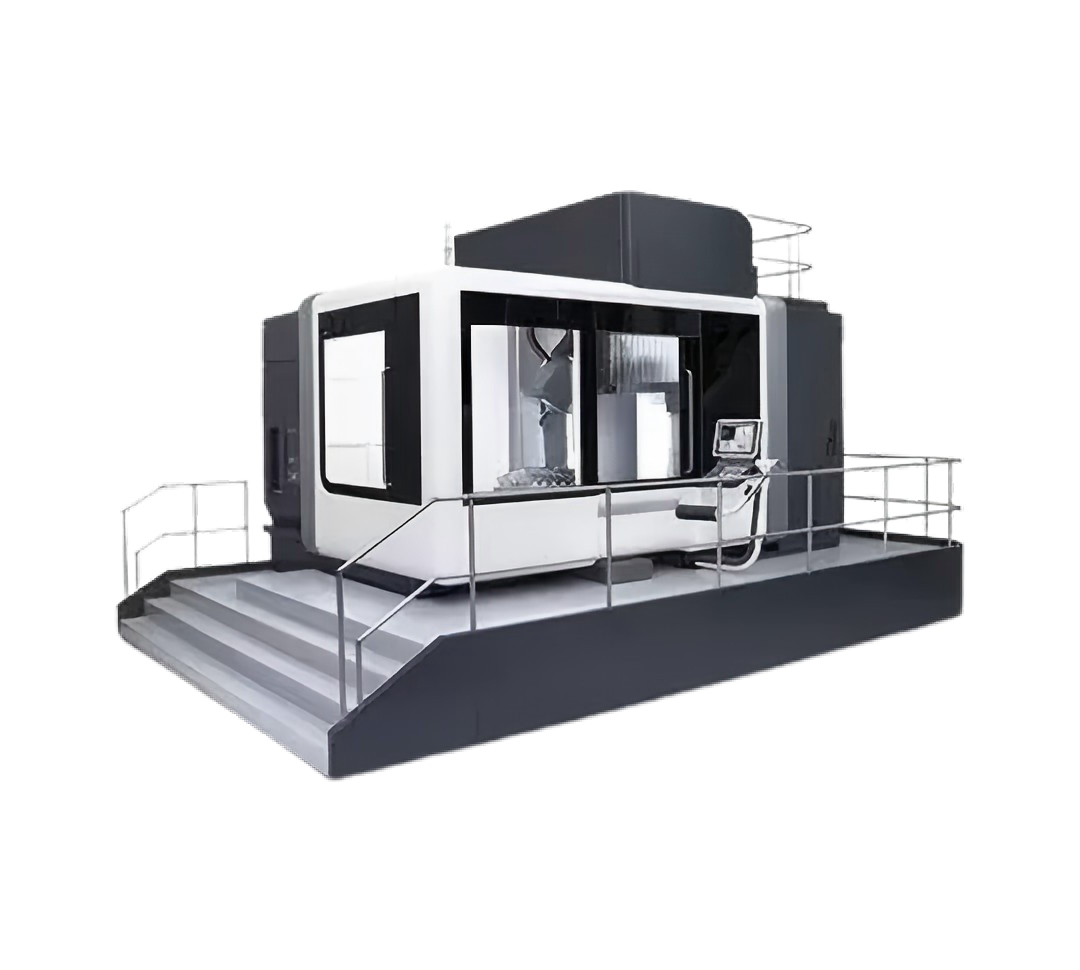

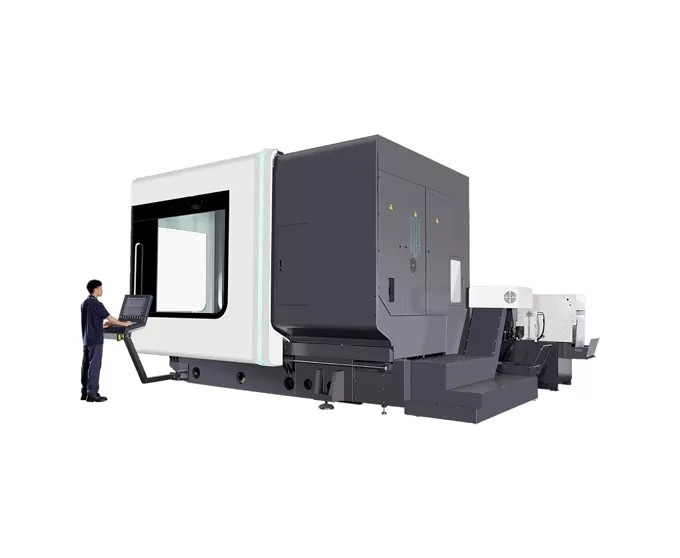

Product introduction

GMC2132 Series machine tool is a mechanical processing equipment integrating advanced technology of machine, electricity and liquid, mainly used for the processing of plane, surface and hole. Widely used in machinery manufacturing industry, a variety of plates, boxes, racks and other complex parts of the rough and finish machining, the machine tool can achieve vertical boring and milling head transverse (Y axis), vertical movement (Z axis) and table longitudinal movement (X axis) of the three-axis linkage. Multi-process machining such as milling, boring, drilling, rigid tapping, reaming and countersinking can be performed.

Product Features:

- The 450*450mm large cross-section fully contained square ram has strong rigidity and large output torque.

- The beam and the horizontal sliding plate are equipped with rolling-sliding composite guide rails as standard, which is not only suitable for powerful cutting, but also has high precision.

- The beam lifting adopts a multi-point lifting positioning mechanism, which has high and stable beam precision and is suitable for processing parts of different heights; the double servo synchronous control of the beam lifting is optional, with high beam positioning accuracy.

- The Z-axis movement adopts the transmission form of double motors and double ball screws, and is controlled by the synchronous axis function of the numerical control system, which makes the movement more stable and the dynamic performance better.

- The optimally designed bed adopts heavy-duty roller linear guide rail, which has strong rigidity and good dynamic performance.

Advantages:

Continuous Innovation

High-tech enterprises, with a number of mature technical teams, annual research and development funds of 2 million, annual research and development of more than 12 new products, 20 national patent technology, continuous innovation.

6S Workshop Standard

36000 ㎡ workshop, 6S workshop standard, workshop through the ISO9001 quality system certification, with complete production equipment, products leave the factory after raw material inspection, process inspection, finished product inspection, products in line with GB and CE standard certification.

Self-built the Factory

Self-built the factory, through the whole industry chain, perfect casting factory, sheet metal factory, CNC machining center, cutting center, processing plant, accessories, the whole process of independent design and development, further reduce the cost, guarantee quality and improve the cost performance.

Our Parnter