Technical Data

| Items | Machine Model: M6230 | M6230A | M6230B | M6230C |

| Working area | ||||

| Worktable size (L×W) | 1270x300mm | 1370x300mm | 1270x300mm | 1370x300mm |

| T slot (Width x No. x pitch) | 14x3x80mm | |||

| Max. load of table | 300kg | |||

| Table rotation | optional: ±45˚ | |||

| Distance from spindle nose to table | 100-500mm | |||

| Travels | ||||

| Worktable longitudinal travel (X) | 720mm | 820mm | 900mm | 1000mm |

| Worktable cross travel (Y) | 300mm(If with DRO:280mm) | 380mm(If with DRO:360mm) | ||

| Worktable vertical travel (Z) | 400mm | |||

| Spindle | ||||

| Spindle speed | 11 steps; 45-1660rpm | |||

| Spindle taper | 7:24, ISO40 | |||

| Motor power | 3kW | |||

| Milling head swivel angel | ±360° | |||

| Feed | ||||

| Rapid feed (X/Y/Z) | 1335/1335/1000mm/min | |||

| Feed range (X/Y) | 30-830mm/min | |||

| Feed range (Z) | 23-625mm/min | |||

| Others | ||||

| Machine size (L×W×H) | 1730x1760x1700mm | 1830x1760x1700mm | 1730x1760x1700mm | 1830x1760x1700mm |

| Net weight | 1800kg | 1850kg | 1850kg | 1900kg |

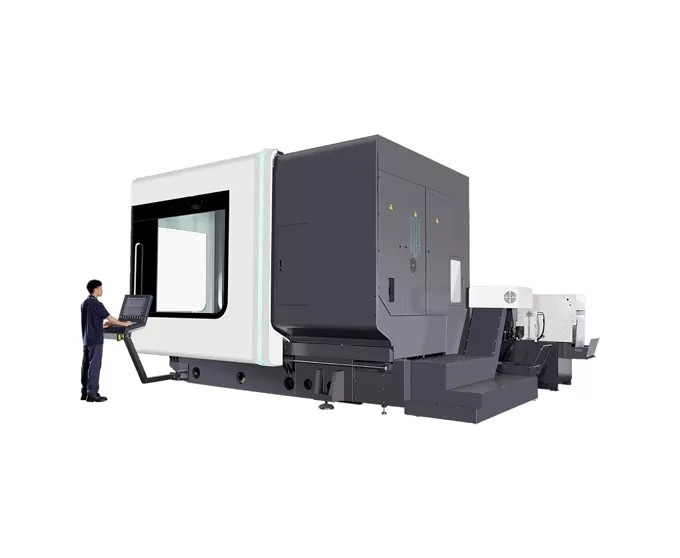

Product introduction

M6230 series Universal Swivel Head Milling machine the whole machine has a compact structure, beautiful and pleasant appearance. Its suitable for drilling , hole-expansion, reaming, bevel edge,and tapping, for surface milling, step plane ,slope ,and milling groove , for cutting and milling curve ,curve surface and cam.Have the function of step-less speed and automatic speed change to gain large torque with low speed, suitable for processing thick cutting depth and larger-diameter hole.The fuselage and main components are high strength cast iron, micro structure stability, ensure the stability of machine tool for long-term use.

Product Features:

- Universal vertical head can swivel 360°, swivel head can change between vertical and horizontal milling mode

- Spindles are driven by gearbox directly, for powerful milling

- Work table feed is driven by servo motor, good accuracy, low noise, and easy to operate. One lever can select table feed directions

- Brief design of control panel, for easy operation (DRO is optional)

Accessories:

- Standard Equipment:

Mill cutter holder ISO40-Ф27

8pcs milling chuck with collects ISO40

Machine vise 5”

Draw bar

Lifting crank

Working lamp

Coolant system

Tool & tool box

Operator manual

- Optional accessories:(need extra cost)

3-axis Digital Read Out

Dividing head 100mm (manual)

Rotary table 200mm

Machine vise 6”

15pcs milling chuck with collects

58pcs Clamping kits

New design aluminum hang arm

Spindle protection cover

Worktable protection cover

LED work lamp

Automatic centralized oil lubrication

Schneider electric components

Advantages:

Continuous Innovation

High-tech enterprises, with a number of mature technical teams, annual research and development funds of 2 million, annual research and development of more than 12 new products, 20 national patent technology, continuous innovation.

6S Workshop Standard

36000 ㎡ workshop, 6S workshop standard, workshop through the ISO9001 quality system certification, with complete production equipment, products leave the factory after raw material inspection, process inspection, finished product inspection, products in line with GB and CE standard certification.

Self-built the Factory

Self-built the factory, through the whole industry chain, perfect casting factory, sheet metal factory, CNC machining center, cutting center, processing plant, accessories, the whole process of independent design and development, further reduce the cost, guarantee quality and improve the cost performance.

Our Parnter