Technical Data

| Items | Units | M6132 | M6132B | M6132BH | M6140 |

| Table size | mm(“) | 1325×320 (52×13) | 1600×320 (63×13) | 1600×320 (63×13) | 1700×400 2000×400(option) 2200×400(option) |

| Table load | kg | 500 | 500 | 500 | 800 |

| Table travel | mm | 700/680 255/240 320/300 | 900/880 255/240 320/300 | 900/880 255/240 410/390 | 900/880 315/300 350/330 |

| T slot (number-width*pitch) | mm | 3-18*70 | 3-18*70 | 3-18*70 | 3-18*90 |

| Table feed range | mm /min | XY:23.5-1180 Z:8-394 | XY:23.5-1180 Z:8-394 | XY:23.5-1180 Z:8-394 | XY:23.5-1180 Z:8-394 |

| Table rapid traverse | mm /min | XY:2300 Z:770 | XY:2300 Z:770 | XY:2300 Z:770 | XY:2300 Z:770 |

| Spindle taper | _ _ | ISO50 7:24 | ISO50 7:24 | ISO50 7:24 | ISO50 7:24 |

| Spindle speed range | RPM(Steps) | 30-1500 (18 steps) | 30-1500 (18 steps) | 30-1500 (18 steps) | 30-1500 (18 steps) |

| Swivel angle of table | ° | ±45 | ±45 | ±45 | ±45 |

| Distance between spindle axis and table surface | mm | 30-350 | 30-350 | 30-440 | 30-380 |

| Main motor power | kw | 7.5 | 7.5 | 7.5 | 11 |

| Feed motor power | kw | 2.2 | 3 | 3 | 3 |

| Machine weight | kg | 2700/3000 | 2800/3100 | 2900/3200 | 3950/4200 |

| overall dimension | mm | 2300*1770*1700 | 2600*1770*1700 | 2600*1770*1900 | 2600*1770*1900 |

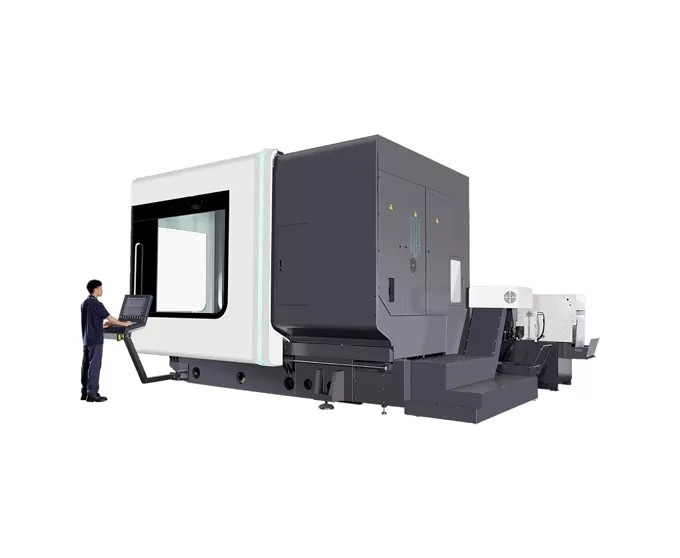

Product introduction

This series of universal lift table milling machine is easy to operate and has reliable performance. It is widely used in various machining departments to process various planes, grooves, gears, etc. Equipped with milling machine accessories such as universal milling head, circular table, indexing head, etc., it can further expand the use range of the machine tool.

Product Features:

- Robust construction and heavy duty design.

- The main driving parts are made of alloy steel.

- Relatively moving parts between machine body and guide rail is PVC laminating treated.

- Sufficient power and large speed range which make full use of the efficiency of tools.

- Can be equipped with hard alloy tools to mill with fast speed.

- The spindle is equipped with impulse device for easier speed adjustment.

- Universal milling head,round working table,dividing head and DRO are for option.

Accessories:

- Standard Equipment

End mill mandrel

Mandrel wrench

Morse taper intermediate sleeve

Milling machine tie rod

Various wrenches

Oil gun

Anchor screw

Block gasket

Tool holder assembly

Advantages:

Continuous Innovation

High-tech enterprises, with a number of mature technical teams, annual research and development funds of 2 million, annual research and development of more than 12 new products, 20 national patent technology, continuous innovation.

6S Workshop Standard

36000 ㎡ workshop, 6S workshop standard, workshop through the ISO9001 quality system certification, with complete production equipment, products leave the factory after raw material inspection, process inspection, finished product inspection, products in line with GB and CE standard certification.

Self-built the Factory

Self-built the factory, through the whole industry chain, perfect casting factory, sheet metal factory, CNC machining center, cutting center, processing plant, accessories, the whole process of independent design and development, further reduce the cost, guarantee quality and improve the cost performance.

Our Parnter