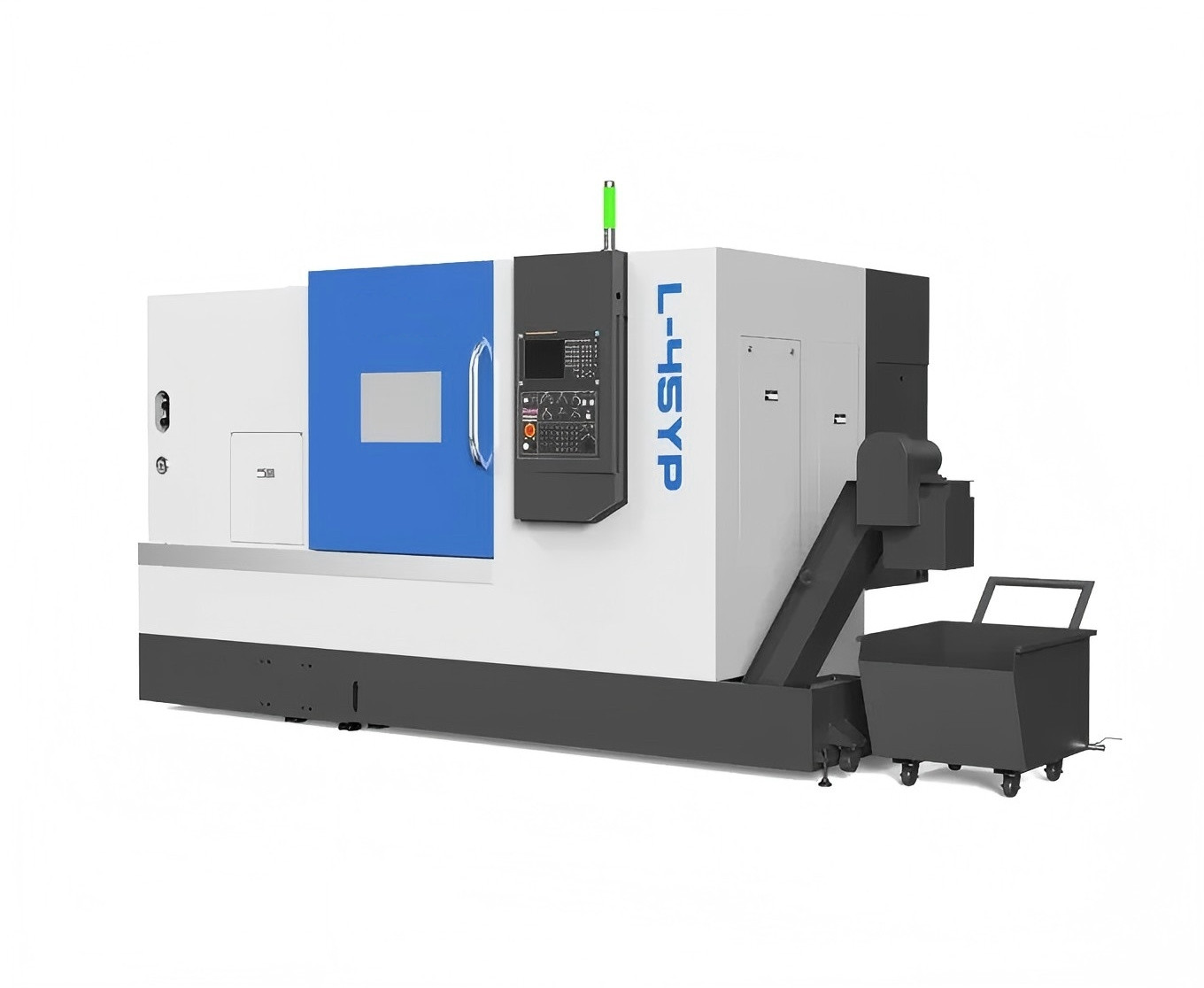

Technical Data

| Items | Unit | Model | |

| L-P46Y | |||

| Machining range | Max. swing diameter on the bed | mm | φ500 |

| Machining diameter (disc type) | mm | Φ300 | |

| Machining diameter on cutter | mm | Φ160 | |

| Machining length | mm | 350 | |

| Travel | X-axis travel | mm | 550 |

| X-axis motor power/stall torque | kW/Nm | 1.8/11 | |

| Z-axis travel | mm | 450 | |

| Z-axis motor power/stall torque | kW/Nm | 1.8/11 | |

| Y-axis travel | mm | 210 | |

| Y-axis motor power/stall torque | kW/Nm | 1.2/7 | |

| Mechanical spindle | Output power (S1/S6) | kW | 7.5/11 |

| Spindle end form | A2-5 | ||

| Spindle speed | r/min | 0-6000 | |

| Spindle through hole diameter | mm | φ56 | |

| Diameter of tie rod through hole | mm | φ46 | |

| Collet | Hollow collet | inch | 6 |

| Motor power | Spindle motor rated/continuous half hour | kw | 7.5/11 |

| X-axis motor | kw | 1.8 | |

| Y-axis motor | kw | 1.2 | |

| Z-axis motor | kw | 1.8 | |

| Tool change motor | kw | 0.75 | |

| Hydraulic motor | kw | 0.75 | |

| Coolant pump motor | kw | 0.45 | |

| Speed | Rapid traverse speed (X-axis) | m/min | 30 |

| Rapid traverse speed (Z-axis) | m/min | 30 | |

| Rapid traverse speed (Y-axis) | m/min | 20 | |

| Cutting feed rate | mm/min | 1~8000 | |

| Tool holder | Tool holder form | Servo tool holder | |

| Tool capacity | T | 8 | |

| External circular tool size | mm | 20×20 | |

| Max. boring tool diameter | mm | Φ25 | |

| Turret center height | mm | 63 | |

| 4+4 power head | Chuck specifications | ER25 | |

| A/B axis (4+4 dual motor) | kw | 1.2/1.2 | |

| A/B axis (4+4 dual motor) | rpm | 0-3000 | |

| Number of A-axis power tools | – | 4×ER25 | |

| Number of B-axis power tools | – | 4×ER25 | |

| Machine tool accuracy | Positioning accuracy (X-axis) | mm | 0.006 |

| Positioning accuracy (Z-axis) | mm | 0.006 | |

| Positioning accuracy (Y-axis) | mm | 0.006 | |

| Repeated positioning accuracy (X-axis) | mm | 0.006 | |

| Repeated positioning accuracy (Z-axis) | mm | 0.006 | |

| Repeated positioning accuracy (Y-axis) | mm | 0.006 | |

| C Axis positioning accuracy | Arc seconds/degree | 10/0.003 | |

| Others | Oil tank | L | 60 |

| Water tank | L | 100 | |

| Machine size (length × width × height) | mm | 2200×2200×2300 | |

| Machine weight (approximate weight) | kg | 3100 | |

Characters

Overall

L-P46Y is a main type of compound machining machine tool. In addition to the functions of CNC lathes, it can also complete plane milling, drilling, tapping, straight groove, spiral groove and gear milling, etc.

Guide rail

The two axes are directly connected by the servo motor and the precision ball screw through the elastic coupling, with good force and high positioning accuracy.

·The X-axis and Z-axis use high-rigidity linear guides. The span between the rails is calculated to obtain the best span, low resistance, high rigidity, high precision, and the displacement speed can reach 30m/min, which improves work efficiency and shortens processing time.

Spindle

The machine adopts an integral sleeve spindle, imported precision spindle bearings, and spindle servo motor drive to achieve high precision, high rigidity, and speed stability. The heat sink-type spindle box design is equipped with symmetrical reinforcement ribs to effectively reduce the spindle temperature rise, increase spindle stability, and increase bearing life.

Tool Turret

Adopt eight-station hydraulic rotary turret, with high positioning accuracy, low failure rate, fast tool change, and local tool change.

Applications

Advantages

Continuous Innovation

High-tech enterprises, with a number of mature technical teams, annual research and development funds of 2 million, annual research and development of more than 12 new products, 20 national patent technology, continuous innovation.

6S Workshop Standard

36000 ㎡ workshop, 6S workshop standard, workshop through the ISO9001 quality system certification, with complete production equipment, products leave the factory after raw material inspection, process inspection, finished product inspection, products in line with GB and CE standard certification.

Self-built the Factory

Self-built the factory, through the whole industry chain, perfect casting factory, sheet metal factory, CNC machining center, cutting center, processing plant, accessories, the whole process of independent design and development, further reduce the cost, guarantee quality and improve the cost performance.

Our partners