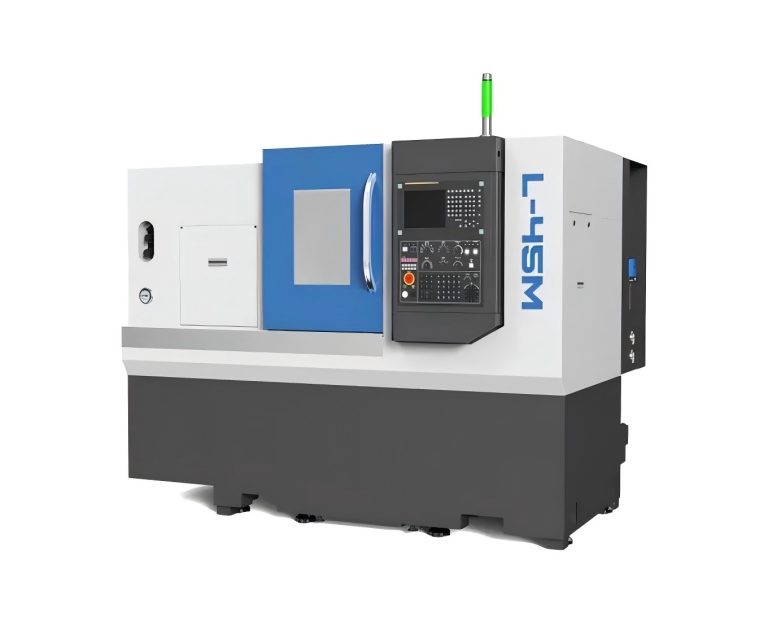

Technical Data

| Items | Unit | Model | Remarks | |

| L-45M | ||||

| Processing range | Max. rotation diameter | mm | φ600 | |

| Max. processing diameter (axis/plate) | mm | φ380/φ450 | ||

| Max. processing length | mm | 400 | ||

| Max. bar diameter | mm | Φ52 | ||

| Travel | X –axis travel | mm | 240 | |

| X –axis motor power/stall torque | kW/Nm | 2.2/12 | ||

| Z –axis travel | mm | 430 | ||

| Z –axis motor power/stall torque | kW/Nm | 2.2/12 | ||

| Spindle | Output power(S1/S6) | kW | 11/15 | |

| Spindle end form | A2-6 | |||

| Spindle rotary speed | r/min | 0-4000 | ||

| Hole diameter | mm | Φ67 | ||

| Chuck | Hydraulic 3-jaw chuck | inch | 8 | Hollow |

| Tailstock | Tailstock sleeve diameter/travel | mm | Φ70/100 | Optional |

| Tailstock sleeve taper hole | Morse | Morse 4# | Live center | |

| Speed | X-axis rapid traverse speed | m/min | 30 | |

| Z-axis rapid traverse speed | m/min | 30 | ||

| Cutting Feed Rate | mm/min | 1~8000 | ||

| Tool holder | Tool capacity | T | 12 | |

| Milling head motor power/stall torque | kW | 2.2/12 | ||

| Milling tool max. speed | r/min | 4000 | ||

| Milling tool handle specification | mm | BMT55 | ||

| Turning tool holder specification | mm | 25×25 | ||

| Max. boring tool diameter | mm | Φ40 | ||

| Accuracy | X axis positioning accuracy | mm | 0.008 | |

| Z axis positioning accuracy | mm | 0.01 | ||

| C axis positioning accuracy | arc sec | 51 | ||

| X axis repeatabilitys | mm | 0.004 | ||

| Z axis repeatability | mm | 0.004 | ||

| C axis repeatability | arc sec | 20” | ||

| Others | Power Supply Capacity | kVA | 30 | |

| Coolant volume | L | 150 | ||

| Dimension | mm | 2300*1880*1800 | ||

| Total weight | kg | 3800 | ||

Description

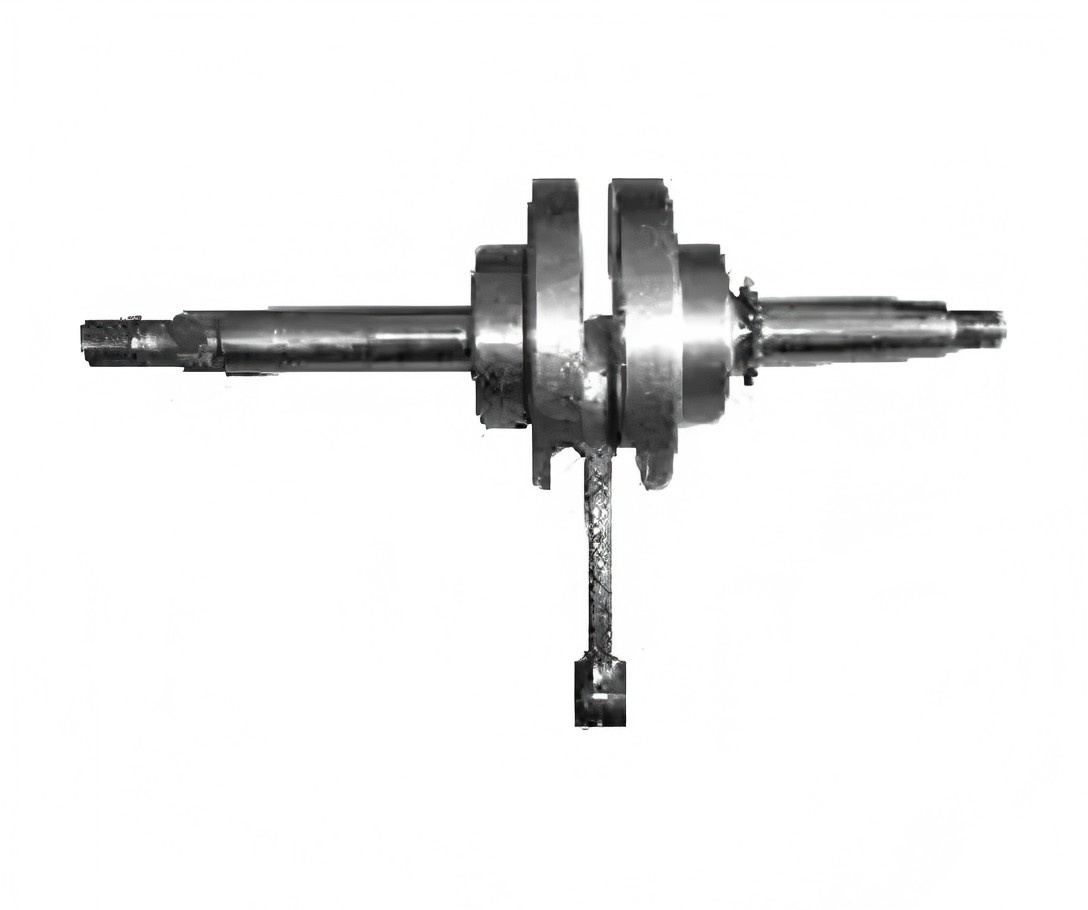

This lathe meets the needs of complex parts processing and is widely used in valves, ships, engineering machinery and other fields, especially favored by automotive parts manufacturers.

Characters

Overall

The machine adopts an integrated machine, electrical, and hydraulic design with a 30°slant bed structure. It is compact, highly rigid, allows for smooth chip removal, and is easy to operate.

Guide rail

The guide rails are of the rolling type, and the drive components use high-speed, quiet ball screws, offering fast speeds, low heat generation, and high positioning accuracy.

Spindle

The main drive system of this machine tool adopts high-performance, high-torque mechanical spindle drive with C-axis indexing function and hydraulic brake auxiliary system, and the spindle speed range is 0-4000r/min.

Tool Turret

This machine tool adopts BMT55 power turret, which has fast tool change speed and high reliability.

Applications

Advantages

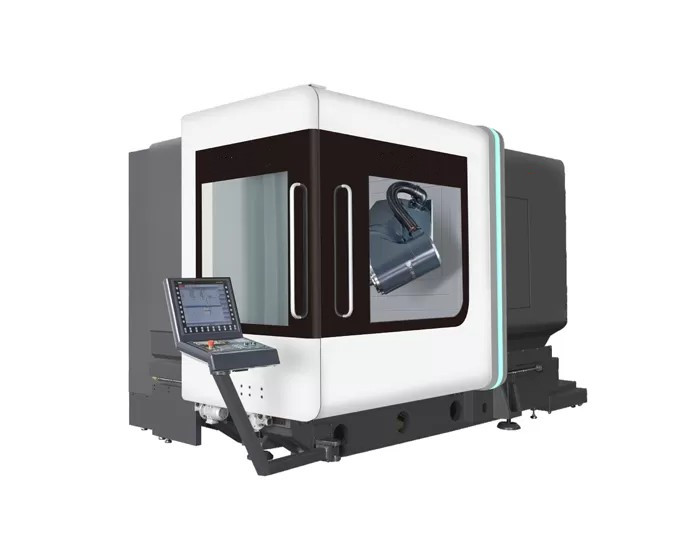

Continuous Innovation

High-tech enterprises, with a number of mature technical teams, annual research and development funds of 2 million, annual research and development of more than 12 new products, 20 national patent technology, continuous innovation.

6S Workshop Standard

36000 ㎡ workshop, 6S workshop standard, workshop through the ISO9001 quality system certification, with complete production equipment, products leave the factory after raw material inspection, process inspection, finished product inspection, products in line with GB and CE standard certification.

Self-built the Factory

Self-built the factory, through the whole industry chain, perfect casting factory, sheet metal factory, CNC machining center, cutting center, processing plant, accessories, the whole process of independent design and development, further reduce the cost, guarantee quality and improve the cost performance.

Our partners