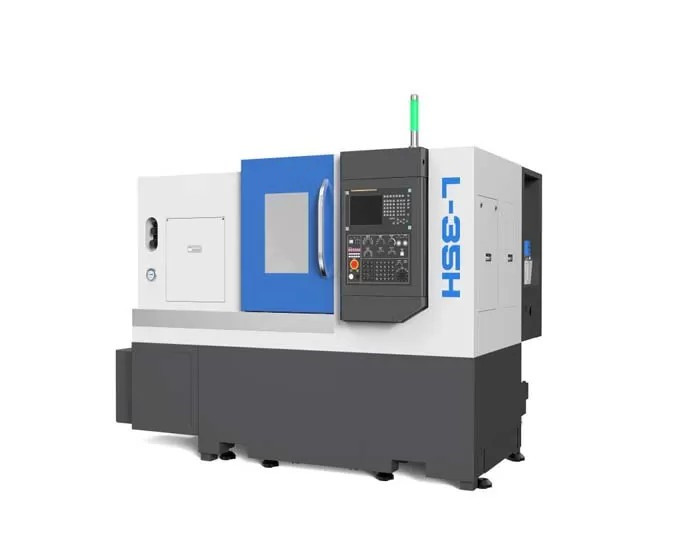

Technical Data

| Items | Unit | Model | Remarks | |

| L-35H | ||||

| Machining range | Max. swing diameter on the bed | mm | φ520 | |

| Max. machining diameter (shaft/disc) | mm | φ300/φ350 | ||

| Max. machining length | mm | 450 | ||

| Max. bar diameter | mm | φ52 | ||

| Travel | X-axis travel | mm | 190 | |

| X-axis motor power/stall torque | kw/Nm | 1.8/11 | ||

| Z-axis travel | mm | 500 | ||

| Z-axis motor power/stall torque | kw/Nm | 1.8/11 | ||

| Spindle | Output power (S1/S6) | kw | 11/15 | |

| Spindle end form | A2-6 | |||

| Spindle speed | r/min | 0-4000 | ||

| Spindle through hole diameter | mm | φ63 | ||

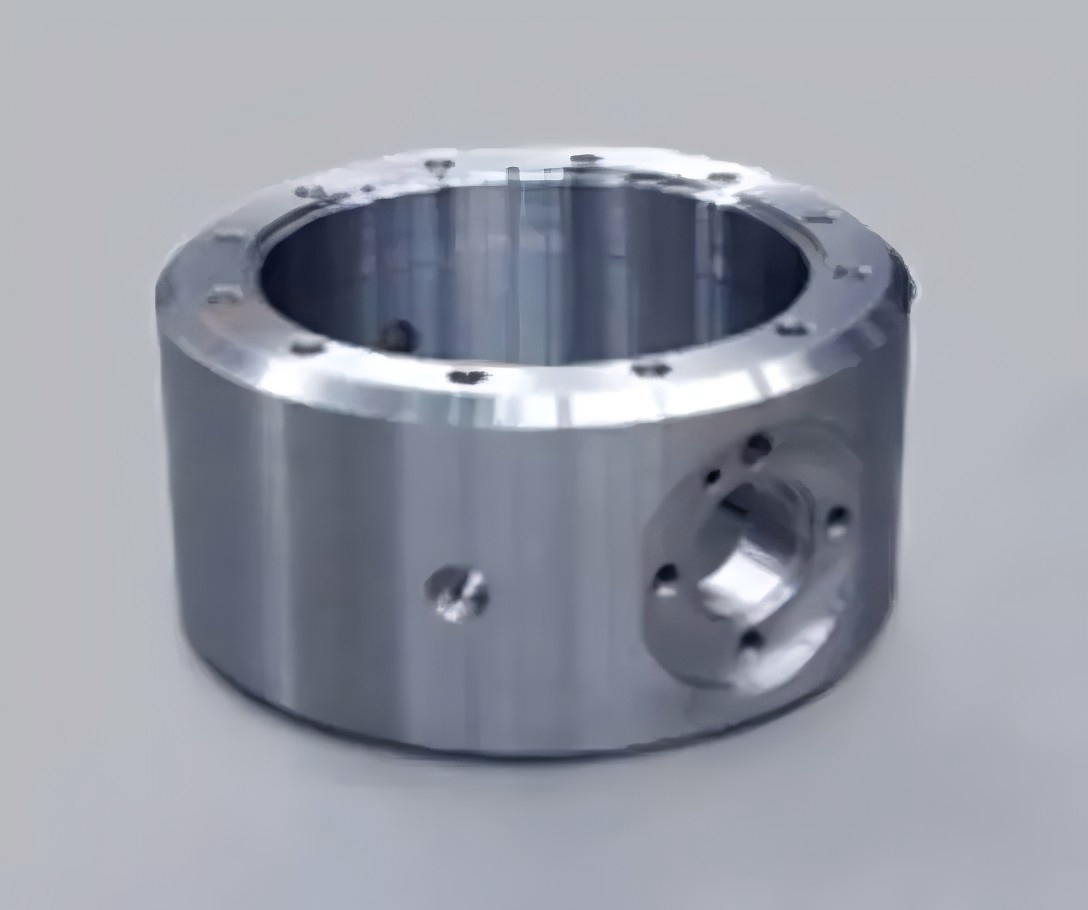

| Chuck | Hydraulic three-jaw chuck | inch | 8 | Hollow |

| Tailstock | Tailstock sleeve diameter/travel | mm | φ70/100 | Optional |

| Tailstock sleeve hole taper | Morse | Morse 4# | Live top | |

| Speed | Rapid traverse speed (X axis) | m/min | 30 | |

| Rapid traverse speed (Z axis) | m/min | 30 | ||

| Cutting feed speed | mm/min | 1~8000 | ||

| Tool holder | Tool capacity | T | 12 | |

| Tool indexing time | Seconds/bit | 0.5 | ||

| Tool body size | mm | 25×25 | ||

| Max. boring tool diameter | mm | 40 | ||

| Accuracy | Positioning accuracy (X axis) | mm | 0.006 | |

| Positioning accuracy (Z axis) | mm | 0.008 | ||

| Repeatability ((X axis) | mm | 0.004 | ||

| Repeatability ( (Z axis) | mm | 0.004 | ||

| Others | Equipment capacity | kVA | 12 | |

| Coolant tank capacity | L | 150 | ||

| Machine size | mm | 2500*1700*1680 | Manual chip removal coolant tank | |

| Weight (approx.) | kg | 3400 | ||

Description

Powerful technology, multiple functions one clamping can complete various processing to meet personalized market manufacturing needs.

Characters

Overall

- Dual-coordinate two-axis linkage, semi-closed loop CNC machine tool. Integrated mechanical, electrical and hydraulic layout.

- ·Each servo feed axis uses a high-speed silent ball screw, directly connected by an elastic coupling, with fast moving speed, low noise, high positioning accuracy and repeatability;

Guide rail

Adopt rolling guide design and high-speed silent ball screw, which has the advantages of high speed, low heat generation and high positioning accuracy.

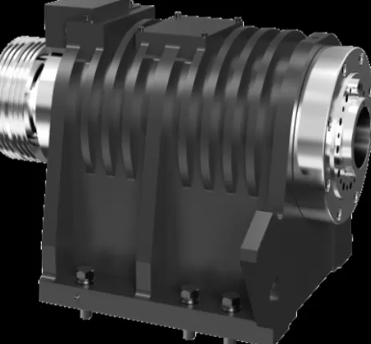

Spindle

- Driven by a high-performance servo motor, the spindle is driven by a belt, and the spindle speed range is 0-4000r/min.

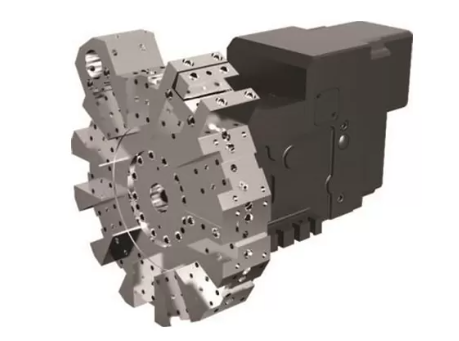

Tool

This machine tool adopts servo tool turret, which has fast tool changing speed and high reliability.

Applications

Advantages

Continuous Innovation

High-tech enterprises, with a number of mature technical teams, annual research and development funds of 2 million, annual research and development of more than 12 new products, 20 national patent technology, continuous innovation.

6S Workshop Standard

36000 ㎡ workshop, 6S workshop standard, workshop through the ISO9001 quality system certification, with complete production equipment, products leave the factory after raw material inspection, process inspection, finished product inspection, products in line with GB and CE standard certification.

Self-built the Factory

Self-built the factory, through the whole industry chain, perfect casting factory, sheet metal factory, CNC machining center, cutting center, processing plant, accessories, the whole process of independent design and development, further reduce the cost, guarantee quality and improve the cost performance.

Our partners