Technical Data

| Items | Unit | Machine Model: FH3235 | |

| Processing Capability | Worktable maximum rotating diameter | mm | 320 |

| The longest distance between two top centers | mm | 500 | |

| Effective grinding length | mm | 350 | |

| Maximum grinding diameter | mm | 320 | |

| Maximum load between two top centers | Kg | 150 | |

| Grinding wheel size: diameter × width × aperture | mm | 510×50×203.2 | |

| Wheel speed | rpm | 1670 | |

| Maximum line speed | m/s | 45 | |

| Control System | CNC Controller (secondary development) | SIEMENS | |

| Wheel head | Feed angle | Deg | 60 |

| X axis feed speed | mm/min | 6000 | |

| X axis feed stroke | mm | 300 | |

| X axis minimum setting unit | mm | 0.001 | |

| Head-stock | Spindle speed | rpm | 0-500 |

| Spindle form | Synchrony/Centering | ||

| Centre | MT 5 | ||

| Tail-stock | Automatic telescopic distance | mm | 40 |

| Centre | MT 4 | ||

| Workbench | Z axis fast moving speed | mm/min | 8000 |

| Z axis minimum setting unit | mm | 0.001 | |

| Maximum travel stroke | mm | 550 | |

| Rotation angle | Deg | 7 / -3 | |

| Motor | Wheel spindle motor | Kw | 7.5 |

| X axis feed motor | Kw | 3.5 | |

| Z axis feed motor | Kw | 3.5 | |

| Headstock spindle motor | Kw | 1.5 | |

| Cooling water motor | Kw | 0.18 | |

| Tail-stock oil pump motor | Kw | 0.75 | |

| Lubricant pump | Kw | 0.1 | |

| Standard accuracy | Roundness | mm | 0.0015 |

| Cylindricity | mm | 0.003 | |

| Straightness | mm | 0.003 | |

| X axis positioning accuracy | mm | 0.003 | |

| Z axis positioning accuracy | mm | 0.003 | |

| X axis repeat positioning accuracy | mm | 0.002 | |

| Z axis repeat positioning accuracy | mm | 0.002 | |

| Roughness | mm | ≤ Ra 0.25 | |

| Others | Machine net weight (full cover type) | Kg | 5000 |

| Gross weight | Kg | 5300 | |

| Packing size (length×width×height) | mm | 4000×3500×2500 | |

Product Introduction

- The grinding wheel spindle has high rigidity, high precision, high service life and low vibration,and low friction.

- The self-aligning function, the wheel spindle is not affected by the belt tension and is biased.

- The spindle has a centering and simultaneous compound function, and the user can perform rapid conversion in the core machining and the chuck clamping process.

- The Z-axis consists of an AC servo motor, a high-precision bead screw, and an automatic forced lubrication system.

- High repeatability, long track service life, high rigidity and smooth reciprocating motion

- Configurable surface measurement, outer diameter thickness measurement, grinding wheel anti-collision device

- The grinding wheel spindle has high rigidity, high precision, high service life and low vibration,and low friction.

- The self-aligning function, the wheel spindle is not affected by the belt tension and is biased.

- The spindle has a centering and simultaneous compound function, and the user can perform rapid conversion in the core machining and the chuck clamping process.

- The Z-axis consists of an AC servo motor, a high-precision bead screw, and an automatic forced lubrication system.

- High repeatability, long track service life, high rigidity and smooth reciprocating motion

- Configurable surface measurement, outer diameter thickness measurement, grinding wheel anti-collision device

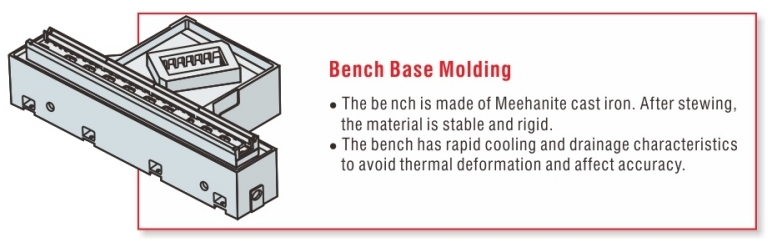

- The be nch is made of Meehanite cast iron. After stewing, the material is stable and rigid.

- The bench has rapid cooling and drainage characteristics to avoid thermal deformation and affect accuracy.

Advantage

Continuous Innovation

High-tech enterprises, with a number of mature technical teams, annual research and development funds of 2 million, annual research and development of more than 12 new products, 20 national patent technology, continuous innovation.

6S Workshop Standard

36000 ㎡ workshop, 6S workshop standard, workshop through the ISO9001 quality system certification, with complete production equipment, products leave the factory after raw material inspection, process inspection, finished product inspection, products in line with GB and CE standard certification.

Self-built the Factory

Self-built the factory, through the whole industry chain, perfect casting factory, sheet metal factory, CNC machining center, cutting center, processing plant, accessories, the whole process of independent design and development, further reduce the cost, guarantee quality and improve the cost performance.

Our parnters