Technical Data

| Items | Machine Model:U6025A | |

| Maximum swivel diameter of the work-piece on the center | 250mm | |

| Maximum distance from centers | 700mm | |

| Work surface size (LxW) | 940x135mm | |

| The maximum vertical movement of the table | 480mm | |

| The maximum rotation angle of the worktable | 120°(60°) | |

| The maximum movement of the grinding head (or slide) in the horizontal direction | 225mm | |

| The minimum distance between the center line of the grinding wheel and the center line of the center | 50mm | |

| The maximum distance between the center line of the grinding wheel and the center line of the center | 265mm | |

| Maximum vertical movement of grinding head | 270mm | |

| The center line of the grinding wheel rises to the center line of the center | 200mm | |

| The center line of the grinding wheel is lowered to the center line of the center | 65mm | |

| The rotation angle of the grinding head is in the horizontal plane | 360° | |

| The rotation angle of the grinding head is in the vertical plane | 30°(±15°) | |

| Spindle end taper | Mors 3# Taper MT 3# | |

| Grinding head motor (50HZ) | Power | 0.85/1.1KW |

| Rotating speed | 1400/2800rpm | |

| Grinding head spindle speed | 3010/6010rpm | |

| Grinding cylindrical attachment motor (50HZ) | Power | 0.25KW |

| Rotating speed | 1400rpm | |

| Machine tool minimum outline size (LxWxH) | 165X115X150(cm) | |

| Machine weight | 940kg | |

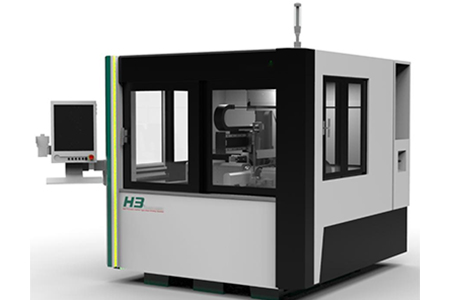

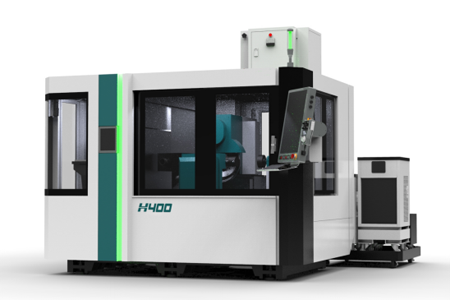

Product Introduction

This machine tool is suitable for sharpening high-speed steel, carbide or other material tools, and is also convenient for grinding outer circles, plane grooves and forming surfaces. If equipped with special accessories, it can also grind various gears, worm gear hobs, forming knives, ball end milling cutters, twist drills, taper reamers, etc.

The grinding wheel frame of the machine tool is flexible and can be adjusted in two degrees. The working head frame can be rotated in both directions. It has an international standard NT50 at one end and a Morse 5# taper hole at the other end, which is convenient for installing various tools and fixtures. The table is supported on preloaded ball guide rails for smooth and precise operation.

Advantages:

Continuous Innovation

High-tech enterprises, with a number of mature technical teams, annual research and development funds of 2 million, annual research and development of more than 12 new products, 20 national patent technology, continuous innovation.

6S Workshop Standard

36000 ㎡ workshop, 6S workshop standard, workshop through the ISO9001 quality system certification, with complete production equipment, products leave the factory after raw material inspection, process inspection, finished product inspection, products in line with GB and CE standard certification.

Self-built the Factory

Self-built the factory, through the whole industry chain, perfect casting factory, sheet metal factory, CNC machining center, cutting center, processing plant, accessories, the whole process of independent design and development, further reduce the cost, guarantee quality and improve the cost performance.

Our Parnter