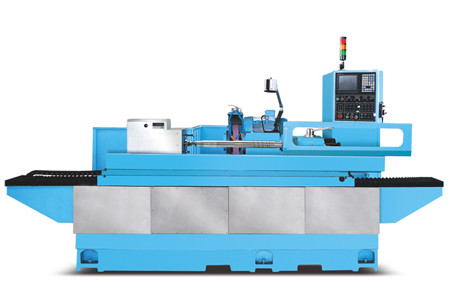

Technical Data

| Item | Unit | Machine Model: TH2760P | |

| processing Capability | Maximum rotating diameter of worktable | mm | 270 |

| The longest distance between two thimble | mm | 600 | |

| Maximum grinding diameter | mm | 270 | |

| Maximum load between two top centers | Kg(b) | 60(Centers work) | |

| 20(Work head work) | |||

| Grinding wheel size (diameter × width × aperture) | mm | 405×38(32-50)×127 | |

| Wheel speed | rpm | 1650 | |

| Maximum linear speed of grinding wheel | m/s | 35(65 with High speed grinding wheel) | |

| Wheel dressing | mm | Automatic | |

| Wheel head | Feed angle | Deg | 90 |

| Feed stroke | mm | 220 | |

| X axis feed speed | m/min | 6 | |

| X axis minimum feed | mm | 0.001 | |

| Head stock | Spindle speed | rpm | 50-500 |

| Spindle form | Simultaneous movement or centering | ||

| Thimble specifications | MT-5 | ||

| Tailstock | Automatic telescopic distance | mm | 40 |

| Center specifications | MT-4 | ||

| Workbench | Z axis fast moving speed | m/min | 8 |

| Z axis minimum feed | mm | 0.001 | |

| Maximum travel stroke | mm | 640 | |

| Rotation angle | Deg | 7 / -3 | |

| Motor | Wheel spindle motor | KW | 3.75 |

| X axis feed motor (servo) | KW | 1.5 | |

| Z axis feed motor (servo) | KW | 1.5 | |

| Headstock spindle motor | KW | 0.75 | |

| Cooling water pump motor | KW | 0.75 | |

| Lubricating oil motor | KW | 0.25*2 | |

| Tailstock oil pump motor | KW | 0.75 | |

| Others | Machine net weight | Kg | 3300 |

| Gross weight | Kg | 3500 | |

| Packing size (length * width * height) | mm | 2700*2000*2000 | |

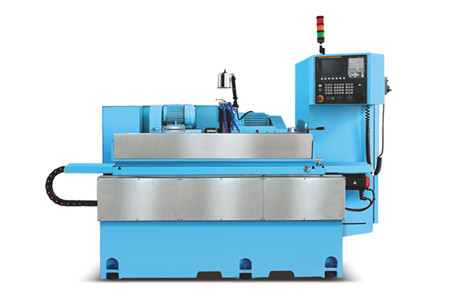

Product Introduction

The grinding wheel dressing device can be selected to achieve precise CNC dressing, adapting to the ordinary outer circular surface, tapered surface, forming outer circular surface, R surface and groove grinding.

The imported or domestic online measuring device is configured to realize the full closed-loop control of the grinding process.

Comprehensive control capabilities such as fault self-diagnosis and abnormal alarm

A robotic automation system can be added to achieve fully automated flow.

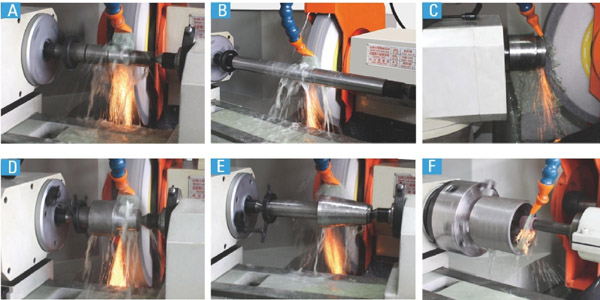

A、Straight Grinding

In small production, the automatic feed is combined with the non-sparking timer for good grinding quality. In the case of mass production, the automatic outer diameter measuring device (special accessory) is installed to provide the best output and grinding effect (CNC model)

B、Cross-grinding

The automatic intermittent feed and hydraulically driven table allow the workpiece to be effectively ground.

C、Face Grinding

Remove the rotating cover of the working spindle head and replace it with a three-jaw or four-jaw chuck. Change the position of the positioning tip to rotate the chuck and fix it at 90 degrees for end grinding.

D、Shoulder Grinding

When the outer diameter of the workpiece and its shoulder need to be finished once, the workpiece is supported by two centerings and the grinding wheel is modified to the right of the grinding wheel head and rotated at an angle to grind.

E、Slope Grinding

The work object can be supported by the chuck or the two centerings, and the work bench and the grinding wheel head can be rotated and adjusted easily

F、Inner Diameter Grinding

Grinding the inner diameter of the inner diameter grinding attachment (special accessory), as long as the inner diameter grinding spindle is pulled down and fxed in the grinding position, it can be ground.

Advantages:

Continuous Innovation

High-tech enterprises, with a number of mature technical teams, annual research and development funds of 2 million, annual research and development of more than 12 new products, 20 national patent technology, continuous innovation.

6S Workshop Standard

36000 ㎡ workshop, 6S workshop standard, workshop through the ISO9001 quality system certification, with complete production equipment, products leave the factory after raw material inspection, process inspection, finished product inspection, products in line with GB and CE standard certification.

Self-built the Factory

Self-built the factory, through the whole industry chain, perfect casting factory, sheet metal factory, CNC machining center, cutting center, processing plant, accessories, the whole process of independent design and development, further reduce the cost, guarantee quality and improve the cost performance.

Our Parnter