Technical Data

| Items | Unit | SGT60160 | SGT60220 | SGT80160 | SGT80220 | SGT80300 | |

| Table size(L*W) | mm | 1600*610 | 2200*610 | 1600*810 | 2200*810 | 3000*810 | |

| Max.grinding size of Work-piece(L*W*H) | mm | 1600*610*600 | 2200*610*600 | 1600*810*600 | 2200*810*600 | 3000*810*600 | |

| Magnetic chuck size | mm | 600*800*2 | 600*1000*2 | 800*800*2 | 800*1000*2 | 800*1000*3 | |

| Table longitudinal speed | mm | 7~23 | 7~23 | 7~23 | 7~23 | 7~23 | |

| Max. loading of table(including magnetic chuck) | kg | 1230 | 1690 | 1630 | 2240 | 3060 | |

| Wheelhead | Auto intermittent feed rate | m/t | 1~30 | 1~30 | 1~30 | 1~30 | 1~30 |

| Transverse | Rapid speed feed | m/min | 0.05-2 | 0.05-2 | 0.05-2 | 0.05-2 | 0.05-2 |

| Moving | Hand-wheel feed per gra. | mm/gra. | 0.005/0.05 | 0.005/0.05 | 0.005/0.05 | 0.005/0.05 | 0.005/0.05 |

| Vertical | Wheel head rotation | mm/t | ±30°, ±5° | ±30°, ±5° | ±30°, ±5° | ±30°, ±5° | ±30°, ±5° |

| Wheel | Rapid speed feed | m/min. | 0.05-2 | 0.05-2 | 0.05-2 | 0.05-2 | 0.05-2 |

| Moving | Hand-wheel feed per gra. | mm/gra. | 0.005/0.05 | 0.005/0.05 | 0.005/0.05 | 0.005/0.05 | 0.005/0.05 |

| Wheel size(OD*Width*ID) | mm | According to process | According to process | According to process | According to process | According to process | |

| Total rated power | KW | 17 | 17 | 17 | 17 | 19 | |

| Gross weight | kg | 8500 | 9500 | 8500 | 9500 | 14000 | |

| Package dimension(L*W*H) | cm | 480*220*172 | 600*220*172 | 480*220*172 | 600*220*172 | 830*220*172 | |

| 260*227*255 | 260*227*255 | 280*227*255 | 280*227*255 | 280*227*255 | |||

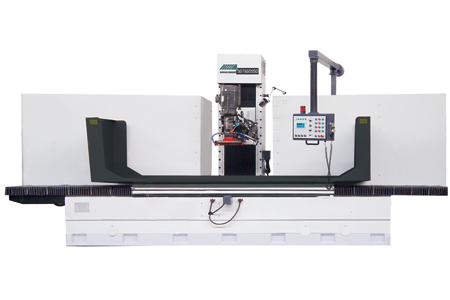

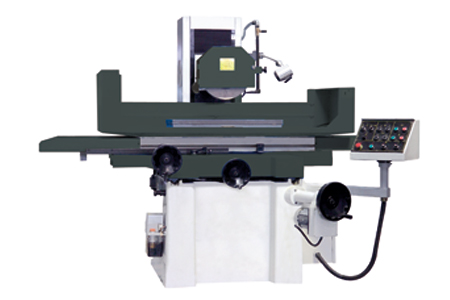

Product Introduction

High strength cast iron foundation

Longitudinal moves hydraulically with variable speed

The transverse and Vertical moves by servo motor and PLC controller realizing auto feed

The spindle equipped with imported high-precision rolling bearings is directly connected with the motor through an elastic coupling.

Table guide adopt flat- V guide and affixed with Teflon wear belt

The grinding head is equipped with an Angle dresser to dress the upper plane of the Angle grinding wheel.

Application

The machine is PLC controlled column moving guide grinder, specialized in grinding machine parts rectangular or dovetail guide, the work-piece can be directly fixed on the workbench or adsorbed on the electromagnetic chuck..

Advantages:

Continuous Innovation

High-tech enterprises, with a number of mature technical teams, annual research and development funds of 2 million, annual research and development of more than 12 new products, 20 national patent technology, continuous innovation.

6S Workshop Standard

36000 ㎡ workshop, 6S workshop standard, workshop through the ISO9001 quality system certification, with complete production equipment, products leave the factory after raw material inspection, process inspection, finished product inspection, products in line with GB and CE standard certification.

Self-built the Factory

Self-built the factory, through the whole industry chain, perfect casting factory, sheet metal factory, CNC machining center, cutting center, processing plant, accessories, the whole process of independent design and development, further reduce the cost, guarantee quality and improve the cost performance.

Our Parnter