Technical Data

| 项目Description | 单位 Unit | SG2050NC2 | SG2550NC2 | SG3063NC2 | SG30100NC2 | SG4080NC2 | SG40100NC2 | |

| SG2050NC3 | SG2550NC3 | SG3063NC3 | SG30100NC3 | SG4080NC3 | SG40100NC3 | |||

| 工作台面积(宽×长) Table size(W×L) | mm | 200×460 | 254×508 | 305×635 | 305×1020 | 406×813 | 406×1020 | |

| 左右最大移动量 Max.longitudinal travel | mm | 510 | 570 | 765 | 1130 | 910 | 1130 | |

| 工作台前后最大移动量Cross tranal | mm | 238 | 275 | 340 | 340 | 450 | 450 | |

| 主轴轴线至工作台面最大距离 Max.distance from spindle center to table | mm | 450 | 450 | 580 | 580 | 580 | 580 | |

| 电磁吸盘尺寸Magnetic chuck size | mm | 200×460 | 250×500 | 300×600 | 300×1000 | 400×800 | 400×1000 | |

| 工作台纵向移动 Table vertical movement | 速度Speed | m/min | 5~25(NC2 model);0.02-15(NC3 model) | |||||

| 电子手轮微量进给量Feed of handwheel | mm/div. | 0.005(NC3 model) | ||||||

| 工作台横向移动 Table transverse movement | 自动进给量 Auto feed | mm/stroke | 0.005~12 | |||||

| 机动速度 Rapid speed | m/min | 0~1 | ||||||

| 电子手轮微量进给量Feed of handwheel | mm/div. | 0.005 | ||||||

| 磨头垂直移动 Wheelhead vertical movement | 自动进给量 Auto feed | mm/stroke | 0.001~0.05 | |||||

| 快速进给 Rapid speed | m/min | 0~1 | ||||||

| 电子手轮微量进给Feed of handwheel | mm/div. | 0.001 | ||||||

| 砂轮 Grinding wheel | 转速Speed | rpm | 50Hz 2850 | 50Hz 1450 | ||||

| 60Hz 3450 | 60Hz 1750 | |||||||

| 尺寸(OD×W×ID)Size | mm | 200×20×31.75 | 350×40×127 | |||||

| 主轴马达Spindle motor | KW | 1.5 | 2.2 | 5.5 | ||||

| 液压站马达Hydranlic motor | KW | 0.75(NC2 model) | 2.2(NC2 model) | |||||

| 冷却泵马达Cooling pump motor | KW | 0.04 | 0.125 | |||||

| 工件加工面对基面的平行度 Paraleism of machined surface to datum plane | mm | 300:0.005 | ||||||

| 工件表面粗糙度 Machined surface roughness | μm | Ra≤0.63 | ||||||

| 工作台最大载重量(含吸盘) Max.loading capacity of table(include magnetic chuck) | kg | 120 | 180 | 270 | 400 | 500 | 600 | |

| 机器高度Height of machine | mm | 1675 | 1890 | |||||

| 占地面积(长×宽)Floor space(L×W) | mm | 2050×1400 | 2300×1600 | 2900×2200 | 4400×2200 | 3600×2400 | 4400×2400 | |

| 毛重Gross weight | kg | 1600 | 1800 | 2800 | 3500 | 3800 | 4300 | |

| 包装尺寸(长×宽×高) Package dimensions (L×W×H) | mm | 1780×1500×2155 | 2000×2100×2150 | 2350×2220×2150 | 2950×2220×2150 | 2850×2270×2180 | 2950×2270×2150 | |

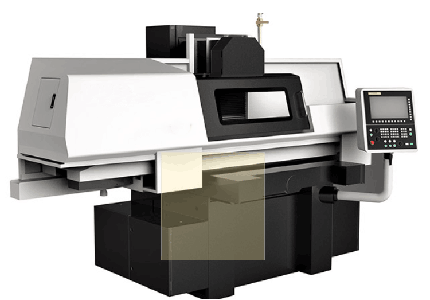

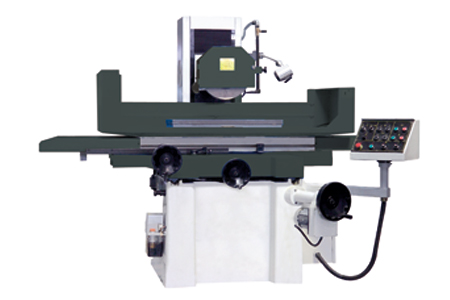

Product Introduction

This series of machine tools are two-axis or three-axis CNC surface grinders. SIMENS, FANUC or other numerical control systems are selected. Widely used in precision mold manufacturing, precision optical parts, precision optical glass, medical devices, mobile phone manufacturing and other precision parts and parts processing; and especially suitable for diamond, ceramic materials, super hard alloy materials processing. This machine tool can also use the end surface of the grinding wheel to grind the vertical plane of the workpiece. During grinding, according to the shape and size of the workpiece, it can be adsorbed on the electromagnetic chuck or directly fixed on the work surface, or it can be held by other fixtures cut.

1. The machine bed, saddle, column, grinding head body, table and other basic parts are all made of high strength cast iron, stable organization and permanent guarantee of quality .

2. The spindle of the grinding head is made of precision angular contact rlling bearing with high rigidity spindle sleeve structure, high rotary precision and easy to use and maintain.

3. NC2 about series of hydraulic drive, feed up and down, front and rear shafts with precision ball screw, AC servo motor and CNC system control, feed high sensitivity, which can realize plane, formed surface (two axes linkage which can realize different grinding wheel dressing, thus realize the formed surface grinding), not equidistant deep range wide groove or ladder automatic grinding, easy to operate with high efficiency.

4. NC3 series feed the left and right, up and down, front and rear three axis are all using precision ball screw, AC servo motor and CNC system control, in addition to the NC2 series function, but also through the left and right, up and down axis linkage to achieve convex concave surface, arc surface and other special shape surface grinding.

Advantages:

Continuous Innovation

High-tech enterprises, with a number of mature technical teams, annual research and development funds of 2 million, annual research and development of more than 12 new products, 20 national patent technology, continuous innovation.

6S Workshop Standard

36000 ㎡ workshop, 6S workshop standard, workshop through the ISO9001 quality system certification, with complete production equipment, products leave the factory after raw material inspection, process inspection, finished product inspection, products in line with GB and CE standard certification.

Self-built the Factory

Self-built the factory, through the whole industry chain, perfect casting factory, sheet metal factory, CNC machining center, cutting center, processing plant, accessories, the whole process of independent design and development, further reduce the cost, guarantee quality and improve the cost performance.

Our Parnter