Technical Data

| Items | Unit | Machine Model:SF27-60 | |

| Processing Capability | Maximum rotating diameter of worktable | mm | 270 |

| The longest distance between two thimble | mm | 600 | |

| Maximum grinding diameter | mm | 270 | |

| Maximum load between two top centers | Kg(b) | 60(Centers work) | |

| 20(Work head work) | |||

| Grinding wheel size (diameter × width × aperture) | mm | 405×38(32-50)×127 | |

| Wheel speed | rpm | 1650 | |

| Maximum linear speed of grinding wheel | m/s | 35(65 with High speed grinding wheel) | |

| Wheel dressing | mm | Automatic | |

| Wheel head | Feed angle | Deg | 90 |

| Feed stroke | mm | 220 | |

| X axis feed speed | m/min | 6 | |

| X axis minimum feed | mm | 0.001 | |

| Head stock | Spindle speed | rpm | 50-500 |

| Spindle form | Simultaneous movement or centering | ||

| Thimble specifications | MT-5 | ||

| Tailstock | Automatic telescopic distance | mm | 40 |

| Center specifications | MT-4 | ||

| Workbench | Z axis fast moving speed | m/min | 8 |

| Z axis minimum feed | mm | 0.001 | |

| Maximum travel stroke | mm | 640 | |

| Rotation angle | Deg | 7 / -3 | |

| Motor | Wheel spindle motor | KW | 3.75 |

| X axis feed motor (servo) | KW | 1.5 | |

| Z axis feed motor (servo) | KW | 1.5 | |

| Headstock spindle motor | KW | 0.75 | |

| Cooling water pump motor | KW | 0.75 | |

| Lubricating oil motor | KW | 0.25*2 | |

| Tailstock oil pump motor | KW | 0.75 | |

| Others | Machine net weight | Kg | 3300 |

| Gross weight | Kg | 3500 | |

| Packing size (length * width * height) | mm | 2700*2000*2000 | |

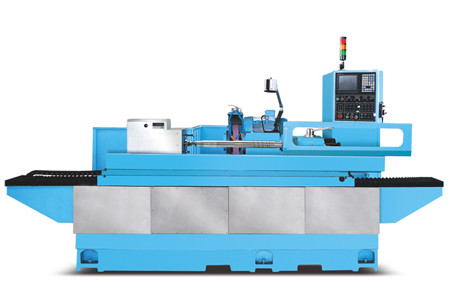

Product Introduction

SF27-60 CNC high precision straight feed cylindrical grinding machine is full cover type, with the truss manipulator. It reclaims and unloads the material automatically.

The grinding machine equipped with active measuring device to realize full closed-loop control of grinding process.

Features :

- This equipment is a fully automatic CNC machining form integrating external cylindrical grinding machine and a robot. It can automatically load and unload in the grinding process, realize one-person multi-machine management mode, minimize labor cost and realize the establishment of industrial production line.

- The Siemens system controls the whole machine operation, including online measurement, and abnormal warning. The robot system can adapt to the processing of work-pieces of different shapes, it can effectively control the precision and consistency of the work-piece.

- The 90-degree rotary robot minimizes the cumbersome loading and unloading, redundant movements, and full monitoring of the work-piece to prevent the product from colliding with the machine and ensuring the safety of the operator.

- The overall structure of the grinding system is compact, maximizing the use of workshop space and excellent overall cost performance.

Advantages:

Continuous Innovation

High-tech enterprises, with a number of mature technical teams, annual research and development funds of 2 million, annual research and development of more than 12 new products, 20 national patent technology, continuous innovation.

6S Workshop Standard

36000 ㎡ workshop, 6S workshop standard, workshop through the ISO9001 quality system certification, with complete production equipment, products leave the factory after raw material inspection, process inspection, finished product inspection, products in line with GB and CE standard certification.

Self-built the Factory

Self-built the factory, through the whole industry chain, perfect casting factory, sheet metal factory, CNC machining center, cutting center, processing plant, accessories, the whole process of independent design and development, further reduce the cost, guarantee quality and improve the cost performance.

Our Parnter