Technical Data

| Diamond Wheel Components (Dressed Wheel Components) | |

| Diamond seconds wheel spindle interface | Optional according to customer requirements |

| diamond grinding wheel diameter | φ420 mm |

| Small diameter diamond grinding wheel | φ20mm |

| Maximum thickness of diamond seconds wheel | 20 mm |

| Dressing wheel aperture | φ31.75mm |

| Spindle speed of diamond grinding wheel | 50-1000rpm (Step-less speed regulation) |

| Diamond grinding wheel spindle cross slide X working stroke | 135 mm |

| Diamond end wheel spindle cross slide X additional manual stroke | 150 mm |

| Diamond grinding wheel spindle cross slide Y working stroke | 135 mm |

| Diamond grinding wheel spindle cross slide Y additional manual stroke | 150 mm |

| X, Y cross slide magnetic scale resolution | 0.001mm |

| Diamond grinding wheel can trim arc radius | R0.1-30mm |

| Silicon Carbide Wheel Components (Dressing Wheel Components) | |

| Dressing wheel (SIC) size | φ180×10×φ31.75 mm |

| Dressing wheel speed | 250-2500 rpm(Stepless speed regulation) |

| Dressing wheel swing times | 0-50/per minute (adjustable speed) |

| Dressing wheel left and right swing distance | 0-45/mm(adjustable) |

| total power | 2.0KW |

| Silicon carbide grinding wheel motor | 0.75KW |

| Dressed diamond wheel motor | 0.75KW |

| Reciprocating swing motor power | 25W |

Product Introduction

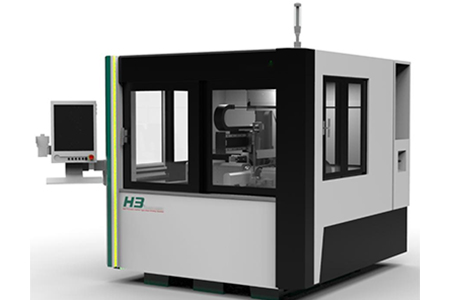

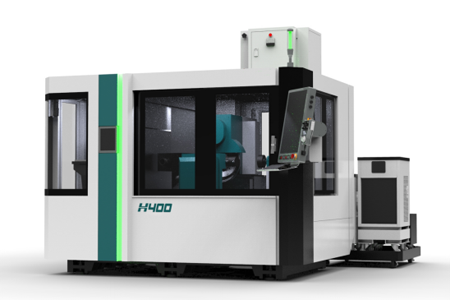

M5 is a fully-sealed grinding wheel dresser introduced in response to the national environmental protection policy to meet the requirements of customers’ workshop environment. lt is a new product based on X3.

The machine itself can provide simple and efficient dressing of diamond wheels, CBN wheels and multiple wheels, it can dress planes, angles, arcs and shaped wheels, The machine is easy to operate and has high accuracy. At the same time, it can achieve water mist cooling and natural cooling without causing environmental pollution.

Advantages:

Continuous Innovation

High-tech enterprises, with a number of mature technical teams, annual research and development funds of 2 million, annual research and development of more than 12 new products, 20 national patent technology, continuous innovation.

6S Workshop Standard

36000 ㎡ workshop, 6S workshop standard, workshop through the ISO9001 quality system certification, with complete production equipment, products leave the factory after raw material inspection, process inspection, finished product inspection, products in line with GB and CE standard certification.

Self-built the Factory

Self-built the factory, through the whole industry chain, perfect casting factory, sheet metal factory, CNC machining center, cutting center, processing plant, accessories, the whole process of independent design and development, further reduce the cost, guarantee quality and improve the cost performance.

Our Parnter