Technical Data

| Items | M1040B | M1050A | M1080B | M10100 | M1083B |

| Plunge feeding Grinding diameter(mm) | 2~40 | 5 ~ 50 | 5 ~ 80 | 10~100 | 10~150 |

| Plunge feeding Grinding length (mm) | 120 | 120 | 140 | 195 | 190 |

| Through feeding Grinding diameter (mm) | 2~40 | 5 ~ 50 | 5 ~ 80 mm | 10~100 | 10~150 |

| Grinding Wheel Spec. (mm) | 350*125*127 | 400*150*203 | 500*150*305 | 500*200*305 | 600*200*305 |

| Regulating Wheel Spec. (mm) | 250*125*75 | 300*150*127 | 300*150*127 | 350*200*203 | 350*200*203 |

| Grinding Wheel Speed (r/min) | 1870 | 1668 | 1300 | 1338 | 1115 |

| Regulating wheel speed (r/min) | 10~200 | 10 ~ 200 | 10 ~ 200 | 10~200 | 10~200 |

| Vertical (degree) | -2°~4° | -2°~5° | -2°~5° | -2°~5° | -2°~5° |

| Horizontal(degree) | 0° ~ 3° | -1° ~ 3° | 0°~ 3° | 0°~ 3° | 0°~ 3° |

| Micro Feed/Division (mm) | 0.002 | 0.002 | 0.0025 | 0.002 | 0.005 |

| Feed/Division (mm) | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 |

| Dresser Feed Amount/Division (mm) | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 |

| Height from center of GW & RW to worktable (mm) | 190 | 220 | 210 | 255 | 285 |

| Grinding wheel motor (KW) | 7.5 | 11 | 15 | 18.5 | 22 |

| Grinding wheel motor (KW) | 1.1 | 1.5 | 1.5 | 2.2 | 3 |

| Power supply | 3N 380V 50HZ | 3N 50HZ 380V | 3N 380V 50HZ | 3N 50HZ 380V | 3N 50HZ 380V |

| Dimension(L*W*H) (mm) | 1550*1300*1405 | 1920*1681*1479 | 1950*1580*1485 | 2675*1505*1615 | 2650x1500x1800 |

| Machine weight (kg) | ≈ 2000kg | ≈ 2800kg | ≈3500 kg | ≈4500 kg | ≈7000 kg |

| Roundness (mm) | 0.002 | 0.002 | 0.002 | 0.002 | 0.002 |

| Cylindricity (mm) | 0.003 | 0.003 | 0.003 | 0.003 | 0.003 |

| Roughness (μm) | Ra0.32 | Ra0.32 | Ra0.32 | Ra0.32 | Ra0.32 |

Product Introduction

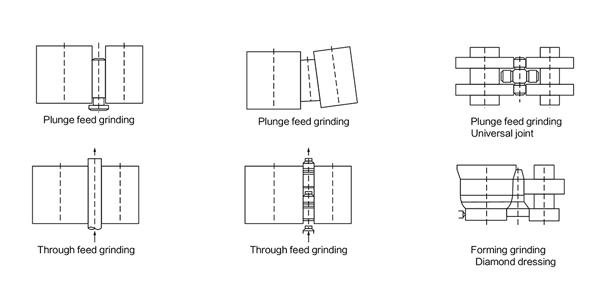

Through grinding : It is mainly used for grinding cylindrical surfaces of various ring and shaft parts.

Plunge-feed : Hand-cut grinding is carried out on all kinds of stepped, tapered and cylindrical rotating surfaces.

Product Application Areas: Bearing, Auto parts, Construction Machinery, Other related field.

CNC System & Software : SIEMENS, FANUC, MITSUBISHI

Machine Tool Main Features

- Bed body

Normalization heat treatment and natural aging treatment of high-quality castings are adopted to stabilize the internal structure and ensure firmness, wear resistance and small deformation during use.

- Grinding wheel and guide wheel device

1. The machine tool adopts the layout of fixed grinding wheel frame and movable guide wheel frame.

2. The grinding wheel is cantilever structure, and the spindle of the grinding wheel adopts multi-piece long bearing hydrodynamic oil film bearing.

3. The guide wheel is cantilever structure, and the main shaft of the guide wheel adopts integral 1:30 cone sliding bearing.

- Feed device

The main feed slide adopts needle roller guide rail, which is sensitive in movement, high in feed accuracy and long in service life.

- Dressing device

The grinding wheel and guide wheel dresser adopt hydraulic transmission and stepless speed regulation.

- Electrical control device

The speed regulation of guide wheel adopts AC variable frequency stepless speed regulation.

Operation Applications

Advantage

Continuous Innovation

High-tech enterprises, with a number of mature technical teams, annual research and development funds of 2 million, annual research and development of more than 12 new products, 20 national patent technology, continuous innovation.

6S Workshop Standard

36000 ㎡ workshop, 6S workshop standard, workshop through the ISO9001 quality system certification, with complete production equipment, products leave the factory after raw material inspection, process inspection, finished product inspection, products in line with GB and CE standard certification.

Self-built the Factory

Self-built the factory, through the whole industry chain, perfect casting factory, sheet metal factory, CNC machining center, cutting center, processing plant, accessories, the whole process of independent design and development, further reduce the cost, guarantee quality and improve the cost performance.

Our parnters