Technical Data

| Item | Unit | Machine Model:H400 |

| C Axis | ||

| Stroke | Deg | ∞ |

| Maximum speed | rpm | 500 |

| Positioning accuracy | Deg | 0.006° |

| Repeatability of positioning accuracy | Deg | 0.001° |

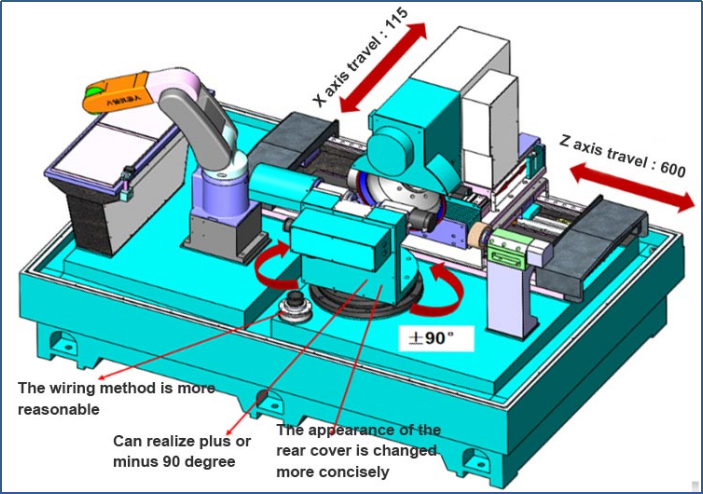

| X Axis | ||

| Stroke | mm | 115 |

| Rapid feed rate | mm/min | 10000mm/min |

| Cutting feed rate | mm/min | 0~3600mm |

| Positioning accuracy | mm | 0.005 |

| Repeatability of positioning accuracy | mm | 0.002 |

| Z Axis | ||

| Stroke | mm | 600 |

| Rapid feed rate | mm/min | 10000mm |

| Cutting feed rate | mm/min | 0~3000 |

| positioning accuracy | mm | 0.01 |

| Repeatability of positioning accuracy | mm | 0.005 |

| B Axis | ||

| Stroke | Deg | -90°~+90° |

| Rapid feed rate | °/s | 200 |

| Cutting feed rate | °/s | 0~90° |

| Repeatability of positioning accuracy | Deg | 0.002° |

| Grinding wheel shaft parameters | ||

| Wheel diameter | mm | 400 |

| Rotating speed | rpm | 0~4000 |

| power | Kw | 7.5 |

| Offline trimmer | ||

| Wheel diameter | mm | 150 |

| Maximum speed | rpm | 8000 |

| Power | KW | 0.8 |

| Online dresser (optional) | ||

| Wheel diameter | mm | 150 |

| Maximum speed | rpm | 8000 |

| Stroke | mm | 0~63 |

| Dressing feed rate | mm/min | 0~720 |

| Shaft power | Kw | 0.8 |

| Processing parameters ( different specifications need to replace tooling) | ||

| Maximum thickness | mm | 35 |

| Maximum diameter | mm | φ50 |

| C-axis tooling clamping (depending on the product can be enlarged) | ||

| Clamp force | N | 200~2500 |

| Installed Capacity | ||

| Total power | KW | 25 |

| Size (length*width*height) | mm | 3400*3600*1900 |

| Oil cooling filter device size (optional) | mm | 1800*1200*1500 |

| Machine weight | kg | 7500 |

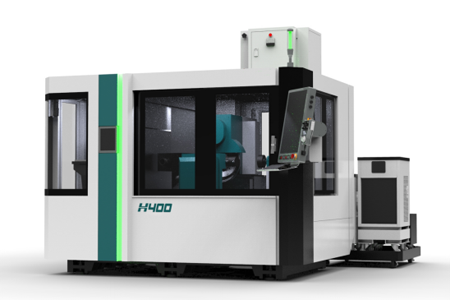

Product Introduction

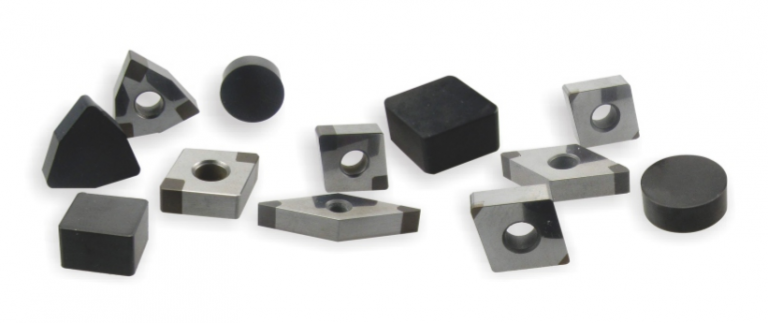

H400 peripheral grinder machine is a four-axis CNC grinding machine center, which is mainly suitable for the grinding of grooving and cutting tools of materials such as cemented carbide, ceramic and CBN. It adopts advanced numerical control system, and can realize loading and unloading by six-axis robot, which can realize various angle rotation, reducing blade turning process, further improving efficiency and shortening grinding time. The grinding of various standard and non-standard tools can also be realized by changing the tooling.

Advantages:

Continuous Innovation

High-tech enterprises, with a number of mature technical teams, annual research and development funds of 2 million, annual research and development of more than 12 new products, 20 national patent technology, continuous innovation.

6S Workshop Standard

36000 ㎡ workshop, 6S workshop standard, workshop through the ISO9001 quality system certification, with complete production equipment, products leave the factory after raw material inspection, process inspection, finished product inspection, products in line with GB and CE standard certification.

Self-built the Factory

Self-built the factory, through the whole industry chain, perfect casting factory, sheet metal factory, CNC machining center, cutting center, processing plant, accessories, the whole process of independent design and development, further reduce the cost, guarantee quality and improve the cost performance.

Our Parnter