Technical Data

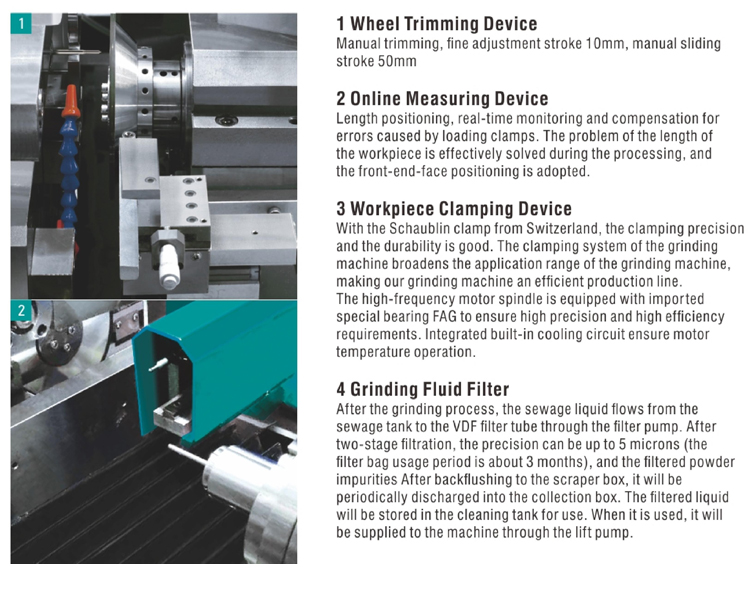

| Item | Unit | Model: H3 | |

| Clamping work-piece diameter rang | mm | 0.5-20 | |

| Grinding work-piece diameter range | mm | 0.05-20 | |

| Clamping / grinding work-piece Maximum length | mm | 300/200 | |

| Control system (CNC-4 axis) | ANCA-X/Y/Z/Z′ | ||

| Feeding and receiving station system (CNC-3 axis) | ANCA-U/V/W | ||

| Rough grinding | Grinding wheel size (diameter) × width × Aperture) | mm | 250×20×31.75 |

| Grinding wheel speed | rpm | 0~8500(Motorized spindle) | |

| Maximum linear speed of grinding wheel | m/s | 90 | |

| Grinding wheel spindle motor | KW | 8.5/20 | |

| Fine grinding | Grinding wheel size (diameter) × width × Aperture) | mm | 150×20×31.75 |

| Grinding wheel speed (motorized spindle) | rpm | 0~12000(Motorized spindle) | |

| Grinding wheel maximum linear speed | m/s | 90 | |

| Grinding wheel spindle motor | KW | 5 | |

| X/Y/Z/Z′axis Minimum feed rate | mm | 0.001 | |

| X-axis stroke (rough grinding axle) | mm | 100 | |

| Y-axis stroke (fine grinding wheel axle) | mm | 29 | |

| Z-axis stroke (working head) | mm | 380 | |

| Z ‘axis stroke (fourth axis) | mm | 55 | |

| X/Y/Z/ Z′axis servo motor | KW | 2 | |

| Head spindle table motor | KW | 1 | |

| Working head Spindle speed | rpm | 0-2000 | |

| High pressure oil pump | KW | 0.25 | |

| Working head spindle rotation mode | fixed | ||

| Support length positioning mode | Front positioning | ||

| Manipulator U / V / W axis servo motor | KW | 1 | |

| Grinding fluid tank | mm | 300*300*1000 | |

| Gross weight (approx.) | Kg | 5000 | |

| Overall dimension (length) × wide × High) | mm | 2450*1980*2000 | |

Product Introduction

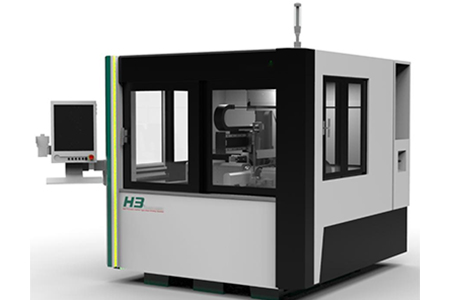

H3 High precision CNC step grinding machine fully automatic peripheral grinder Product Introduction :

Product introduction :

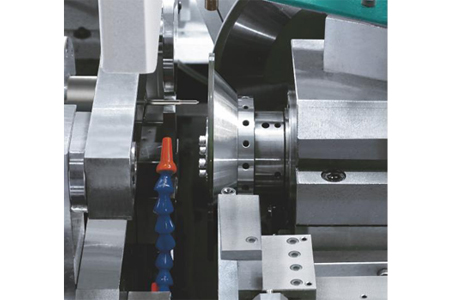

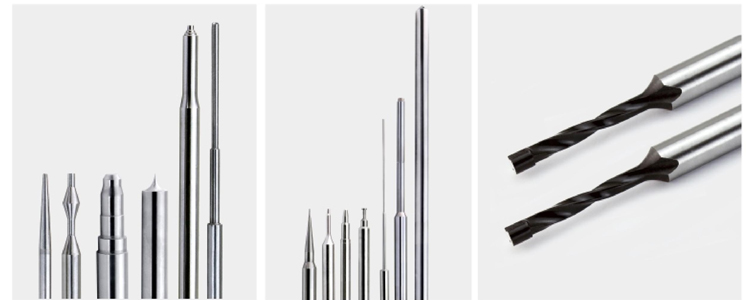

The walking center level difference grinder adopts a special walking center structure, which can grind multiple stages of work-pieces within 0.05-20 mm. It adopts the Chinese secondary development highly automated grinding system developed by Australian ANCA company, which can freely move and rearrange buttons and icons. The creation interface of multi-step and complex interrupted work-pieces can be realized without programming, and the interactive touch screen technology with high performance can easily realize more advanced gesture commands.

Advantages:

Continuous Innovation

High-tech enterprises, with a number of mature technical teams, annual research and development funds of 2 million, annual research and development of more than 12 new products, 20 national patent technology, continuous innovation.

6S Workshop Standard

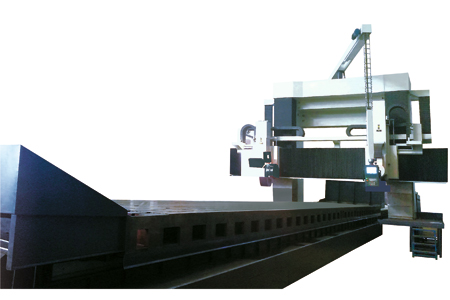

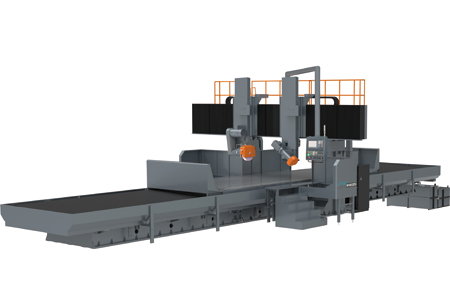

36000 ㎡ workshop, 6S workshop standard, workshop through the ISO9001 quality system certification, with complete production equipment, products leave the factory after raw material inspection, process inspection, finished product inspection, products in line with GB and CE standard certification.

Self-built the Factory

Self-built the factory, through the whole industry chain, perfect casting factory, sheet metal factory, CNC machining center, cutting center, processing plant, accessories, the whole process of independent design and development, further reduce the cost, guarantee quality and improve the cost performance.

Our Parnter