Technical Data

| Items | Unit | Machine model:H250 | |

| Maximum Swing Diameter | mm | 250 | |

| Maximum distance between two thimbles | mm(in) | 500 | |

| Maximum lapping diameter | mm(in) | 250 | |

| Processing capability | Maximum load between the centers | Kg(b) | 40(centre works)/ |

| 20(only work head) | |||

| Grinding wheel size (diameter × width × aperture) | mm(in) | 405×32~50×127 | |

| Grinding wheel speed | rpm | 1570 | |

| Maximum linear velocity of grinding wheel | m/s | 35 | |

| Wheelhead | Grinding wheel dressing | mm(in) | Automatic |

| X axis minimum feed | mm(in) | 0.001 | |

| Feed Angle | Deg | 90 | |

| Feed travel | mm | 270 | |

| The X-axis fast moving speed | mm/min | 0-10000 | |

| Headstock | Spindle speed | rpm | 10-650 |

| Spindle form | Synchrony or centering | ||

| Thimble specifications | MT-4 | ||

| Tailstock | Automatic telescopic distance (hydraulic type) | mm | 40 |

| Thimble specifications | MT-4 | ||

| Operation mode | Manual | ||

| Workbench | Z axis fast moving speed | mm/min | 0-20000 |

| Z axis minimum feed | mm | 0.001 | |

| Maximum travel stroke | mm | 550 | |

| Rotation angle | Deg | +6/-9 | |

| Motor | Wheel spindle motor | KW | 3.75 |

| X axis feed motor (servo) | KW | 2.2 | |

| Z axis feed motor (servo) | KW | 2.2 | |

| Headstock spindle motor | KW | 0.37 | |

| Cooling water pump motor | KW | 0.75 | |

| Lubricating oil motor | KW | 1/4*2 | |

| Tail seat oil pump motor (special) | KW | 0.75 | |

| Others | X/Z axis guide/screw lubrication oil | MOBIL#1409 or ISO VG68 class oil | |

| Machine net weight | Kg | About 3500 | |

| Machine gross weight | Kg | About 3800 | |

| Package size(L*W*H) | mm | 2900*2600*1750 | |

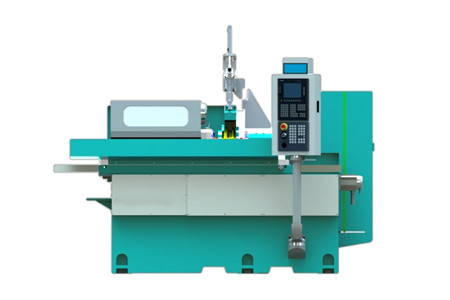

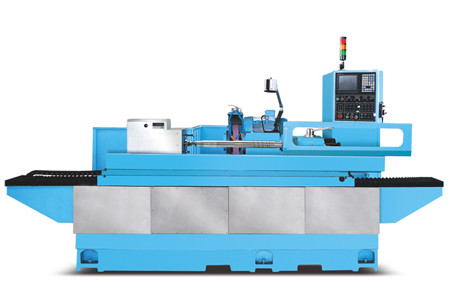

Product Introduction

1) Take use of Siemens 808D CNC CNC system, grinding special friendly man-machine interface, no programming, processing program automatically generated.

2) Equipped with high-precision bearing-type grinding wheel spindle and precision-ground ball screw.

3) Two-axis servo drive automatic feed, automatic dressing of the grinding wheel, can meet the shaping and dressing of various steps, arcs, and curved surfaces, and the system automatically compensates.

4) All sliding surfaces, contact surfaces and guide rail surfaces adopt manual grind and shovel technology to ensure the high precision and long-term stability of the machine.

5) All sliding surfaces, contact surfaces and guide rail surfaces adopt manual grind and shovel technology to ensure the high precision and long-term stability of the machine.

6)The machine castings are strictly selected FC25 high-grade cast iron, and the aging treatment ensures that the basic components of the machine tool are not deformed.

Product features:

1. The machine tool control system is the German Siemens 808DCNC CNC system, which is a special man-machine interface for grinding developed by Siemens. The operation is simple and easy to learn, and the processing program is automatically generated without manual programming.

2. The grinding wheel spindle is the bearing spindle of the Taiwanese brand, and the whole is imported from Taiwan, with strong grinding force, high rotation accuracy and excellent stability.

3. The taper of the work-piece head-stock spindle is (MT#4), and the head stock motor can be continuously variable. This spindle can be a movable and fixed dual-purpose structure.

4. The taper of the tail stock spindle is (MT#4), manual operation.

5. Both X-axis and Z-axis servo motors use Siemens high-inertia servo motors.

6. Electrical accessories: relays, contactors, switch buttons are all Japanese “Fuji” brand.

7. Both the X-axis and Z-axis feed screws use Japanese THK grinding grade ball screws.

8. Both the grinding wheel motor and the head stock motor use Taiwan TECO Motor.

9. The coupling uses the Japanese NBK brand.

10. The standard grinding wheel flange (5″) of the machine tool is a set of Taiwan’s Miqi brand.

11. The standard grinding wheel of the machine tool is a piece of Norton brand (405.40.127).

12. The standard configuration of the machine tool is a half-shielded waterproof sheet metal (front-mounted sliding glass door splash cover).

13. The machine tool electrical control box is equipped with industrial refrigeration and air-conditioning, and three-color intelligent warning lights.

14. The machine tool body and important castings are processed with advanced machining equipment such as YASDA, ELB, SIP, etc. to ensure the high precision of the basic components of the machine tool.

15. All sliding surfaces, contact surfaces and track surfaces adopt manual shoveling technology to ensure the high precision and long-term stability of the machine.

16. The machine tool castings are strictly selected FC-25 high-grade cast iron.

Advantages:

Continuous Innovation

High-tech enterprises, with a number of mature technical teams, annual research and development funds of 2 million, annual research and development of more than 12 new products, 20 national patent technology, continuous innovation.

6S Workshop Standard

36000 ㎡ workshop, 6S workshop standard, workshop through the ISO9001 quality system certification, with complete production equipment, products leave the factory after raw material inspection, process inspection, finished product inspection, products in line with GB and CE standard certification.

Self-built the Factory

Self-built the factory, through the whole industry chain, perfect casting factory, sheet metal factory, CNC machining center, cutting center, processing plant, accessories, the whole process of independent design and development, further reduce the cost, guarantee quality and improve the cost performance.

Our Parnter