Technical Data

| Items | Unit | GC150 | GC150-I |

| Grinding inner dia. range | mm | Φ6-150 | Φ6-200 |

| Grinding hole for the longest depth | mm | 150(Integrated spinde max. | 200 |

| grinding depth: 300mm) | |||

| Bench rotation dia. | mm | 520 | 520 |

| Rotation dia. inside the | mm | 320 | 320 |

| waterproof cover | |||

| Max. stroke of the | mm | 540 | 540 |

| workbench | |||

| Workpiece spindle | r.p.m. | 0~3000 | 0~3000 |

| rotation speed | |||

| Spindle table slide | m/min | 8 | 8 |

| feed speed | |||

| X-axis feed rate | m/min | 8 | 8 |

| X-axis min. moving unit | mm | 0.001 | 0.001 |

| Z-axis min. moving unit | mm | 0.001 | 0.001 |

| Spindle table rotation | Forward 15° backward2″ | Forward 15° backward2″ | |

| adjustment angle | |||

| Feeding method | |||

| Feeding method | Servo motor | Servo motor | |

| Wheel motor | 2HP | 2 (Three-phase motor) | 2 (Three-phase motor) |

| X-axis servo motor | KW | 1.5(1 axis) | 1.5(1 axis) |

| Z-axis servo motor | KW | 2 | 2 |

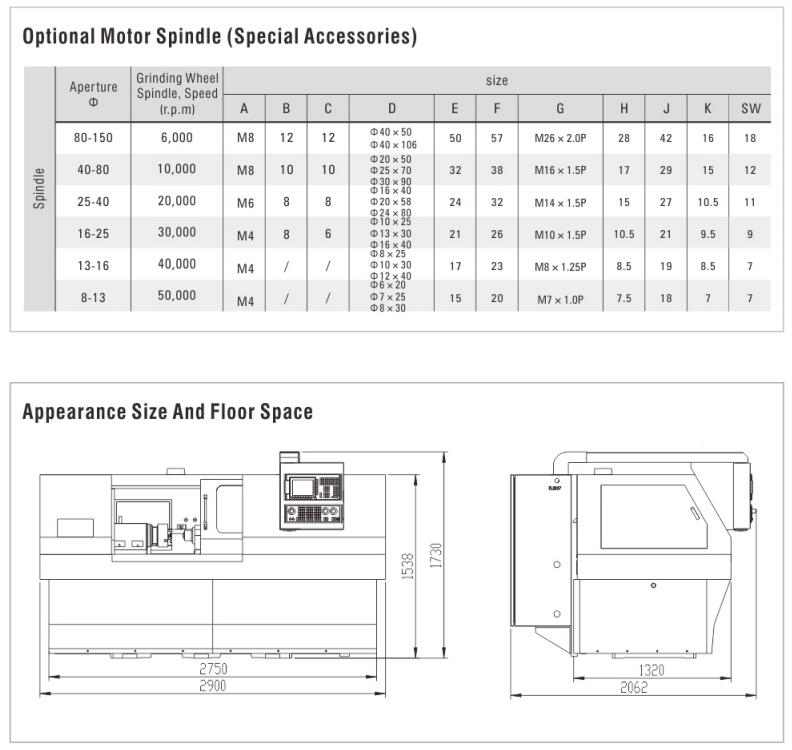

| Floor area | mm | 2500LX2100W | 2500LX2100W |

| weight (about) | KG | 3000 | 3200 |

Product Introduction

The body design is ergonomically designed for easy operation

- Compact internal grinding machine with small installation space and suitable for any workshop

- The sliding surface adopts static pressure automatic lubrication system, which has smooth movement and good wear resistance.

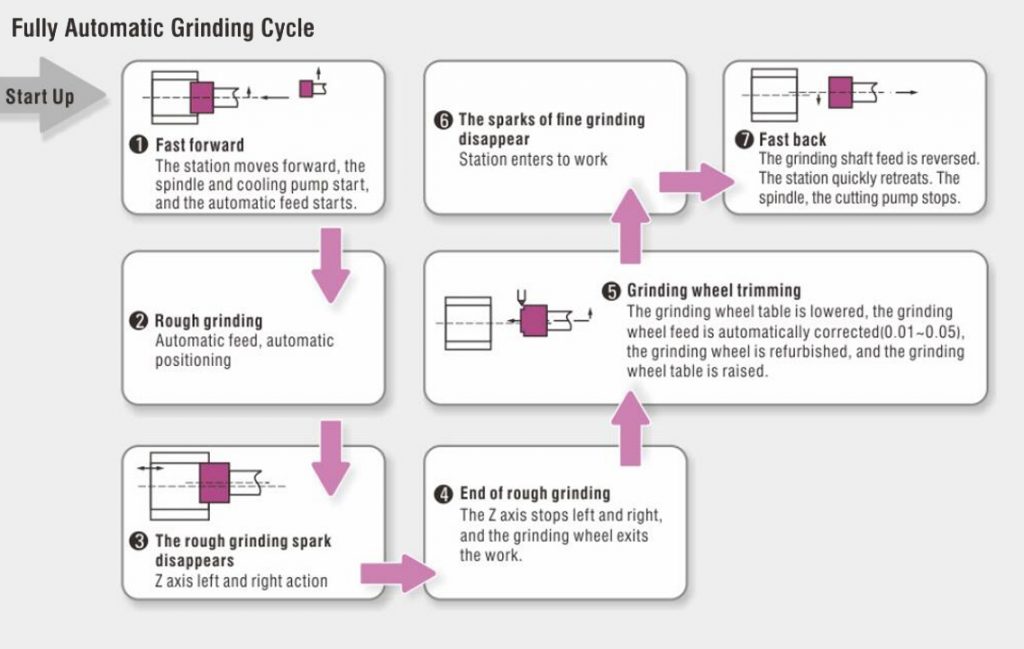

- Fully automatic grinding: rough grinding, dressing, fine grinding, non-sparking grinding cycle action. High precision, easy operation and greatly increased production capacity. Suitable for mass production and grinding of a small amount of different form workpieces.

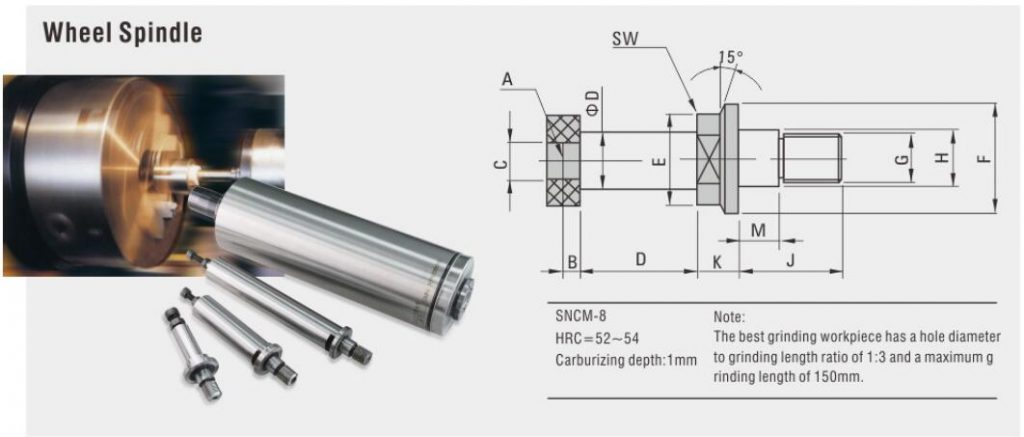

- The head frame rotates with P4 high-precision spindle bearings, featuring high precision, high rigidity and quiet operation.

- The feed shaft is equipped with a precision ball screw, which is driven by a servo motor and can be fed without a section.

- Dressing mode is CNC automatic correction and dressing

- (1) If you use diamond or CBN grinding wheel, you can choose not to correct the dressing mode.

- (2) For workpieces that are difficult to grind, multiple correction modes can be selected to ensure the best processing quality.

- In mass production, automatic production equipment such as automatic feeding and automatic unloading can be installed.

Accessories:

Standard Equipment

1. Grinding cooling device (water tank/ water

pump/ water pipe)(1 set)

2. Diamond trimming pen (1 pcs)

3. Angle adjustment table (1 pcs)

4. Toolbox (hex wrench set/ Open end wrench/

screwdriver) (1 pcs)

5. Spindle grinding wheel post (3 pcs)

6. High-speed grinding spindle (RMP optional) (1 pcs)

7. Basic adjustment block (6 pcs)

Optional Equipment

1. Hydraulic three-jaw chuck

2. Chuck flange

3. Mechanical spindle: 10,000/20,000/30,000rpm

Electric spindle: 40,000/100,000rpm

4. End face detecting device

5. Magnet filter

6. Paper tape filter

7. Closed full cover and automatic door

8. Inner diameter automatic measuring device

Advantages:

Continuous Innovation

High-tech enterprises, with a number of mature technical teams, annual research and development funds of 2 million, annual research and development of more than 12 new products, 20 national patent technology, continuous innovation.

6S Workshop Standard

36000 ㎡ workshop, 6S workshop standard, workshop through the ISO9001 quality system certification, with complete production equipment, products leave the factory after raw material inspection, process inspection, finished product inspection, products in line with GB and CE standard certification.

Self-built the Factory

Self-built the factory, through the whole industry chain, perfect casting factory, sheet metal factory, CNC machining center, cutting center, processing plant, accessories, the whole process of independent design and development, further reduce the cost, guarantee quality and improve the cost performance.

Our Parnter