Technical Data

| Items | Unit | Machine model:GA45 | |

| Processing capability | Maximum grinding diameter | mm | Φ400 |

| Grinding outer diameter length | mm | 200 | |

| Outer wheel size | mm | Φ405*32-60*127 | |

| Grinding inner diameter range | mm | Φ6-200 | |

| Depth of grinding inner diameter | mm | 200 | |

| Maximum length of work聽piece | mm | 260 | |

| Spindle speed of inner hole grinding wheel | rpm | 20000/40000 | |

| (Electric Spindle) | |||

| Wheel dressing | mm | Automatic | |

| CNC system | Set | SIEMENS | |

| Height of grinding wheel spindle center to ground | mm | 1150 | |

| Work Head | Spindle speed | rpm | 0-1000 |

| X axis fastest feed speed | mm/min | 10000 | |

| X axis minimum feed unit | mm | 0.001 | |

| Working head rotation angle | Deg | +15~-5(manual) | |

| Workbench | Z axis fast moving speed | mm/min | 18000 |

| Z axis minimum feed | mm | 0.001 | |

| Maximum travel stroke | mm | 250 | |

| Motor | External wheel spindle motor | KW | 3.75 |

| Internal spindle motor | KW | 3 | |

| X axis feed motor (servo) | KW | 1.5 | |

| Z axis feed motor (servo) | KW | 1.5 | |

| Headstock spindle motor | KW | 1.2 | |

| Cooling water pump motor | KW | 0.37 | |

| Lubricating oil motor | KW | 0.25*2 | |

| Others | Coolant tank capacity | L | 200 |

| Machine weight | Kg | 6500 | |

| Equipment size (length * width * height) | mm | 2300*2200*2000 | |

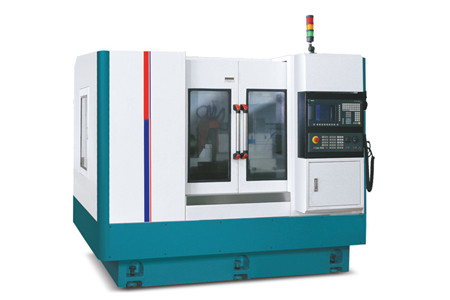

Product Introduction

The GA45 CNC grinding machine is a complex solution for high-precision grinding of small and medium-sized workpieces. It is suitable for machine tool industry, automotive engineering, tool and mold industry, aerospace industry, pneumatics/hydraulics, electronics/electrical engineering, medical technology watch industry and order production industry.

Comprehensive Features

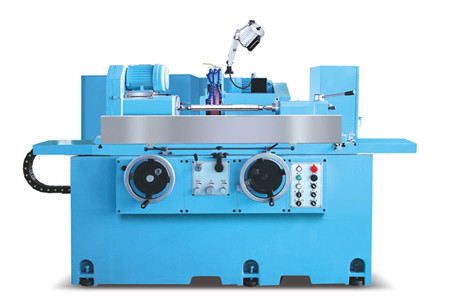

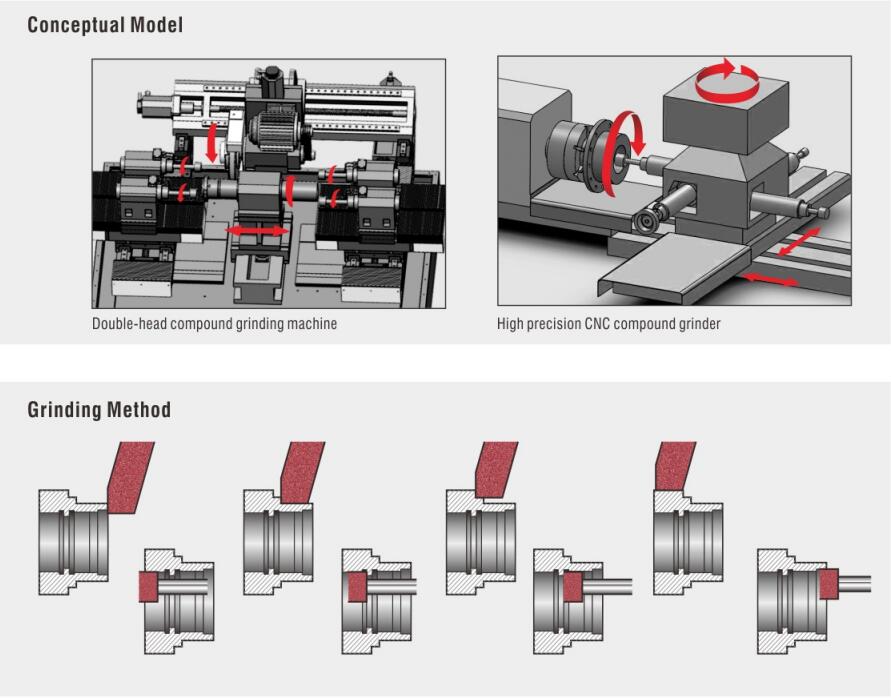

It can grind outside-diameter and internal part with one time clamping. Provides a complex solution for high-precision grinding of small and medium-sized workpieces.

Machine tool industry, automotive engineering, tool and mold industry, aerospace industry, pneumatic / hydraulic, electronic /

Modular design, you can choose different grinding wheel spindle combination to fully meet the processing all the requirements.

The control system interface makes the operation and programming system very simple and easy to learn. The programming software directly programs the workpiece grinding and grinding wheel on the machine control system, it can also be programmed on an external computer.

It can be equipped with automatic load and unload system to meet the needs of industrialized mass production.

Advantages:

Continuous Innovation

High-tech enterprises, with a number of mature technical teams, annual research and development funds of 2 million, annual research and development of more than 12 new products, 20 national patent technology, continuous innovation.

6S Workshop Standard

36000 ㎡ workshop, 6S workshop standard, workshop through the ISO9001 quality system certification, with complete production equipment, products leave the factory after raw material inspection, process inspection, finished product inspection, products in line with GB and CE standard certification.

Self-built the Factory

Self-built the factory, through the whole industry chain, perfect casting factory, sheet metal factory, CNC machining center, cutting center, processing plant, accessories, the whole process of independent design and development, further reduce the cost, guarantee quality and improve the cost performance.

Our Parnter