Technical Data

| Items | Unit | G5316 | G5320 | G5325 | G5330 | G5335 |

| Table width | mm | 1250 | 1600 | 2000 | 2500 | 3000 |

| Table length | m | 2.0/2.5/3.5/4 | 2.5/3.5/4.5/6/8 | 3.5/4.5/6/8/10/12/14/15/16 | 8/10/12/13/14/15/16 | 8/10/12/13/14/15/16 |

| Max. grinding height | mm | 950 | 950 | 950 | 950 | 950 |

| Max.wheel center to table | mm | 1250 | 1250 | 1250 | 1250 | 1250 |

| Column distance | mm | 1600 | 2000 | 2500 | 3000 | 3500 |

| Horizontal wheel head motor | kw | 22 | 22 | 22 | 30 | 30 |

| Horizontal wheel size | mm | φ600*120*203 | φ600*120*203 | φ600*120*203 | φ600*120*305 | φ600*120*305 |

| Horizontal spindle speed | mm | 1050 | 1050 | 1050 | 1050 | 1050 |

| Vertical head motor | mm | 11 | 11 | 11 | 15 | 15 |

| Vertical wheel size | mm | φ400*75*127 | φ400*75*127 | φ400*75*127 | φ400*75*127 | φ400*75*127 |

| Vertical spindle speed | mm | 800-2500 | 800-2500 | 800-2500 | 800-2500 | 800-2500 |

| Vertical head rotation | ° | ±90 | ±90 | ±90 | ±90 | ±90 |

Product Introduction

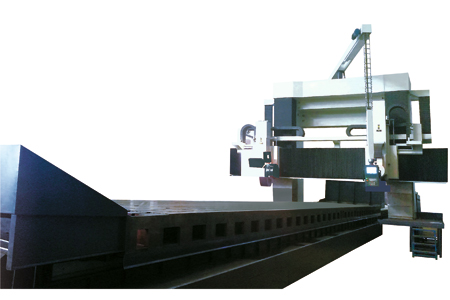

G53 Series Double Column Gantry guide grinder Product Introduction :

This series of machine tools adopts a gantry layout, and consists of a closed high-rigidity frame structure composed of double columns, beams and bed. It is a program-controlled (NC) fixed-beam gantry rail grinder integrating advanced technologies such as machinery, electricity, and hydraulics. Grinding

Product Features

Hydro-static bearing has the advantages of high motion accuracy, no wear, long life, small starting power, high bearing capacity and good vibration resistance at high speed

Longitudinal moves hydraulically with variable speed

CNC rotary table is used to drive the vertical head,the min.division is 0.01 degree.

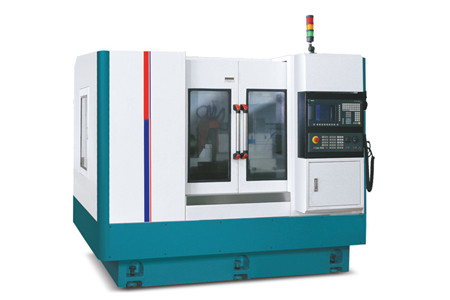

MKW series means the machine can be configured with the CNC system to expand to 2 axis CNC machine.

Application

The machine is a fixed beam type gantry guide grinder, can grind medium and large work-piece plane and various machine guide..

Advantages:

Continuous Innovation

High-tech enterprises, with a number of mature technical teams, annual research and development funds of 2 million, annual research and development of more than 12 new products, 20 national patent technology, continuous innovation.

6S Workshop Standard

36000 ㎡ workshop, 6S workshop standard, workshop through the ISO9001 quality system certification, with complete production equipment, products leave the factory after raw material inspection, process inspection, finished product inspection, products in line with GB and CE standard certification.

Self-built the Factory

Self-built the factory, through the whole industry chain, perfect casting factory, sheet metal factory, CNC machining center, cutting center, processing plant, accessories, the whole process of independent design and development, further reduce the cost, guarantee quality and improve the cost performance.

Our Parnter