Technical Data

| Items | Unit | Machine Models | ||||||||

| G1420 | G1432B | G1450 | G1463 | |||||||

| General capacity | ||||||||||

| Max.length ground(O.D) | mm | 500,750 | 1000,1500,2000,3000 | 1500,2000,3000,4000 | 2000,3000,4000,5000 | |||||

| Center height | mm | 125 | 180 | 270 | 370 | |||||

| Dia.Ground(O.D) | mm | 8~200 | 8~320 | 25-500 | 30~630 | |||||

| Dia.Ground(I.D) | mm | 30-80 | 30-100 | 30-200 | 30~250 | |||||

| Max.length ground(LD) | mm | 125 | 125 | 320 | 320 | |||||

| Max.weight of work piece | Kg | 50 | 150 | 1000 | 3000 | |||||

| Workhead | ||||||||||

| Swiveling angle | 。 | +90° | +90° | +90° | +90° | |||||

| Center taper(MT) | (MT) | 3 | 4 | 6 | Metnc 80#V | |||||

| Spindle speed /Stepless | r/min | 50HZ:60~460 | 50HZ-26-260 | 50HZ:20~224 | 50HZ:14~140 | |||||

| Wheelhead | ||||||||||

| Max.dimension of wheel(ODxWxID) | mm | 400x40x203 | 500x50x203 | 500x75x305 | 600x75x305 | |||||

| Wheel peripheral velocity | m/s | 35 | 35 | 35 | 35 | |||||

| Hand feed per.rev | mm | 1 | rough:2fine:0.5 | rough:4 fine:0.5 | rough:4 fine:0.5 | |||||

| Hand feed per.gra | mm | 0.00125 | rough:0.01 fine:0.0025 | rough:0.02 fine:0.0025 | rough:0.02 fine:0.0025 | |||||

| Intemal grinding device | ||||||||||

| Spindle speed | r/min | 10000 | 10000 | 10000 | 10000 | |||||

| mm | max 50x25x13 | max50×25×13 | max175x32x32 | max175x32x32 | ||||||

| Dimension of wheel | min 17x20x6 | min17x20x6 | min30x25x10 | min30x25x10 | ||||||

| Table | ||||||||||

| Max.swiveling angle of table | Clockwise | 。 | 5°(500)3°(750) | 3°(1000,1500)2°(20003000) | 3°(1500)2°(2000,3000)1(4000) | 2°2000)1°3000,40005000) | ||||

| Anticlockwise | 。 | 9° | 7°(1000)6°(1500)5°(2000)3°(3000) | 6°(1500)5°(2000)3°(3000)2°(4000) | 4°(2000)3°(3000)2°(4000)1.5°(5000) | |||||

| Longitudinal speed range of table | m/min | 0.1~4 | 0.1~4 | 0.1~3 | 0.1~2.5 | |||||

| Tailstock | ||||||||||

| Center taper(MT) | (MT) | 3 | 4 | 6 | Metric 80# | |||||

| Quill ravel | mm | 25 | 30 | 70 | 70 | |||||

| Motor | ||||||||||

| Wheelhead motor power | KW | 3 | 55(1000,1500752000,3000) | 57.5 | 7/11 | |||||

| Internal grinding | KW | The same Motor with wheelhead | 1.1 | 1.5 | 1.5 | |||||

| Workhead motor power | KW | 0.25/0.37 | 1.5 | 4 | 15 | |||||

| Machining accuracy | ||||||||||

| Roundness | μm | 2 | 3(1000,1500)5(2000,3000) | 3(1500)5(2000,3000,4000 | 5 | |||||

| Cylindricity | μm | 5 | 8(1000,1500)102000,3000) | 8(1500)10(2000,3000)15(4000) | 10(2000,3000)15(4000,5000) | |||||

| Roughness | μm | Ra0.2 | Ra02(100,1500 ) Ra0.32(2000,3000) | Ra0.32 | Ra0.32 | |||||

| Machine | ||||||||||

| Gross weight | T | 2.4(500)2.9(750) | 4.6(1000),5.1(1500)5.7(2000).7.1(3000) | 10(1500),11(2000)13(3000),17(4000) | 18(2000),22(3000)23(4000),26(5000) | |||||

| packing dimension | cm | 192x145x205(500) | 326x190x205(1000) | 543x225x210(1500) | 695x242x226(2000) | |||||

| 426x190x205(1500) | 583x225x210(2000) | 890x242x226(3000) | ||||||||

| 213x145x205(750) | 530x190x205(2000) | 796x225x210(3000) | 1100x242x226(3000) | |||||||

| 730x190x205(3000) | 996×225×210(4000) | 1270x242x226(5000) | ||||||||

| Standard accessories | Optional accessories | |||||||||

| Coolant Tank | Balancing shaft | Wheel balancing stand | Close steady rest | |||||||

| External wheel Dresser | Working light | Magnetic separator | End face wheel dresser | |||||||

| Wheel Flange and loading Tools | Open Steady Rest | Magnetic separator and paper filter | Radius wheel dresser | |||||||

| Standard Gninding Wheel | Center | Center Gninding Device | ||||||||

| Balancing shaft | Internal Grinding Attachment (Only M14 Series) | |||||||||

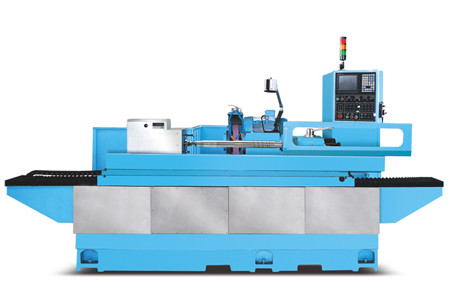

Product Introduction

G1420, G1432B, G1450, G1463 universal cylindrical grinders use electric and hydraulic interlocking mechanisms with various moving parts to ensure safe and reliable operation. It is suitable for grinding IT6-IT5 precision inner and outer cylindrical or conical rotating workpieces. It is suitable for single-piece small batch and batch production workshops.

Product Features :

- The horizontal feed of wheelhead is driven by hydraulic pressure to realize micro automatic periodic feed and fast advance and regress.Also can do manually rough fine feeding.

- G1350, G1450, G1363 series table and wheelhead guide rail adopt static guide rail, low speed motion is stable.

- G1350, G1450,G1363 series wheelhead with high rigid spindle, high rotary precision, good rigidity. The workhead adopts frequency converter to realize stepless speed regulation.

- Universal workhead can be adjusted at any Angle within 90 degrees counterclockwise to adapt to chuck grinding internal and external conical workpiece.

In terms of diameters, the grindable cylindrical diameters range from 8 mm to 320 mm, which can meet the grinding needs of workpieces from finer to larger diameters. For internal bores, the grindable diameters range from 30 mm to 100 mm. In terms of length, the maximum length of grindable cylinders varies according to the model, with common specifications of 1000 mm, 1500 mm, 2000 mm, 3000 mm and other specifications, which can be adapted to the processing of workpieces of different lengths. Among them, the maximum length of grindable bore is up to 125 mm. The grinder can also process workpieces with a maximum weight of 150 kg and can handle parts within a certain weight range.

In addition, the grinding wheel holder is angle adjustable in the horizontal plane (±30°), which greatly expands the machining range and makes it possible to grind not only general external cylindrical surfaces and internal bores, but also short conical surfaces and other workpieces with angular requirements. Both shaft parts and cylindrical workpieces with conical features can be processed on this grinder. This wide range of processing makes G1432 cylindrical grinder highly adaptable in the field of machining, and it can be used in the manufacture of parts in a variety of industries, such as the processing of automobile parts, mechanical transmission components, precision instrument parts, etc. It can meet the grinding needs of different customers for different types and sizes of workpieces, and provide a strong guarantee for the production of high-quality precision parts.

1. Automobile manufacturing industry:

– Processing of automobile parts: It can be used to grind crankshafts, camshafts, transmission shafts and other shaft parts of automobile engines to ensure the dimensional accuracy and surface quality of these key components and improve the performance and reliability of automobile engines. For example, the journal surface of crankshaft requires high finish and precision, and G1432 cylindrical grinder can meet this requirement.

– Automobile brake system parts processing: The grinder is also used for the outer circle and inner hole processing of automobile brake discs and drums to ensure the precision and stability of the braking system and make the automobile more safe and reliable when braking.

2. Mechanical processing industry:

– General mechanical parts processing: it can grind various shafts and sets of parts in general machinery, such as gear shafts, silk rods, sleeves and so on. These parts play an important role in transmission, connection and other important functions in machinery and equipment, and have higher requirements for precision, G1432 cylindrical grinder can meet its processing needs.

– Mold Manufacturing: In the process of mold manufacturing, it is often necessary to process some cylindrical mold parts with high precision requirements, the grinder can be used for the external and internal grinding of the mold to ensure the dimensional accuracy and surface quality of the mold, thus improving the service life of the mold and the molding quality of the product.

3. Aerospace industry:

– Aircraft parts processing: some key parts on the aircraft, such as blades of aircraft engines, shaft parts, landing gear parts, etc., require high machining accuracy and surface quality. East China CNC G1432 cylindrical grinding machine can be used for the precision grinding of these parts to ensure the safe flight of the airplane.

– Aerospace equipment parts processing: some high-precision parts in aerospace equipment, such as transmission shafts of satellites, axis systems of gyroscopes, etc., also need to be processed with high-precision grinding machines, which can meet the strict requirements of aerospace equipment on the precision of parts.

4. Electronic equipment manufacturing industry:

– Electronic equipment parts processing: in electronic equipment manufacturing, there are many small shafts and sets of parts, such as the drive shafts of printers, copiers, toner cartridges, bushings, etc., which require high-precision machining equipment. the G1432 cylindrical grinder can meet the machining requirements of these parts and ensure the normal operation of electronic equipment.

– Semiconductor equipment parts processing: some key parts in semiconductor equipment, such as the wafer carrier shaft, the moving parts of the photolithography machine, etc., require very high machining accuracy and surface quality. The grinder can be used for precision grinding of these parts to support the manufacturing of semiconductor equipment.

5. Medical device industry:

– Medical device parts processing: Some parts in medical devices, such as the shaft of artificial joints and handles of surgical instruments, require high-precision machining equipment. East China CNC G1432 cylindrical grinder can be used for grinding and processing of these parts to ensure the quality and safety of medical devices.

– Medical equipment maintenance: In the maintenance process of medical equipment, it is often necessary to repair some worn shafts and sets of parts, the grinder can be used for the repair and processing of these parts to extend the service life of medical equipment.

Advantages

Continuous Innovation

High-tech enterprises, with a number of mature technical teams, annual research and development funds of 2 million, annual research and development of more than 12 new products, 20 national patent technology, continuous innovation.

6S Workshop Standard

36000 ㎡ workshop, 6S workshop standard, workshop through the ISO9001 quality system certification, with complete production equipment, products leave the factory after raw material inspection, process inspection, finished product inspection, products in line with GB and CE standard certification.

Self-built the Factory

Self-built the factory, through the whole industry chain, perfect casting factory, sheet metal factory, CNC machining center, cutting center, processing plant, accessories, the whole process of independent design and development, further reduce the cost, guarantee quality and improve the cost performance.

Our parnters