Technical Data

| Items | Unit | Machine models | ||||||

| G1320 | G1332 | G1332A | G1350A | G1363 | G1380A | |||

| General capacity | ||||||||

| Max.length ground(O.D) | mm | 500,750 | 1000 ,1500 | 1500,2000,3000 | 1500,2000,3000,4000 | 2000,3000,4000,5000 | 3000,4000,5000 | |

| Center height | mm | 125 | 180 | 180 | 270 | 370 | 500 | |

| Dia.Ground(O.D) | mm | 8~200 | 8~320 | 8~320 | 25~500 | 30~630 | 50~800 | |

| Max.weight of work piece | Kg | 50 | 150 | 500 | 2000 | 3000 | 3000 | |

| Workhead | ||||||||

| Center taper(MT) | (MT) | 3 | 5 | 5 | 6 | 80# | 80# | |

| Spindle speed /Stepless | r/min | 50HZ:25~260 | 50HZ:26~190 | 50HZ:26~190 | 50HZ:10~100 | 50HZ:6~60 | 50HZ:5~50 | |

| Wheelhead | ||||||||

| Max.dimension of wheel(ODxWxID) | mm | 400x40x203 | 600x75x305 | 600x75x305 | 750x75x305 | 750×75×305 | 900x75x305 | |

| Wheel peripheral velocity | m/s | 35 | 35 | 35 | 35 | 35 | 35 | |

| Hand feed per.rev | mm | 1 | rough:2fine:0.5 | rough:2 fine:0.5 | rough:4 fine:0.5 | rough:4 fine:0.5 | rough:4 fine:0.5 | |

| Hand feed per.gra | mm | 0.00125 | rough:0.01 fine:0.0025 | rough:0.01 fine:0.0025 | rough:0.02 fine:0.0025 | rough:0.02 fine:0.0025 | rough:0.02 fine:0.0025 | |

| Table | ||||||||

| Max.swiveling angle of table | Clockwise | 。 | 5°(500)3°(750) | 3° | 3°(1500)2°(2000,3000) | 3°(1500) 2°(2000,3000)1°(4000) | 2°(2000) 1°(3000 4000 5000) | 1°(3000 4000 5000) |

| Anticlockwise | 。 | 9° | 7°(1000)6°(1500) | 6°(1500)5°(2000)3°(3000) | 6°(1500)5°(2000)3°(3000)2°(4000) | 4°(2000) 3°(3000)2°(4000)1.5°(5000) | 3°(3000)2°(4000)1.5°(5000) | |

| Longitudinal speed range of table | m/min | 0.1~4 | 0.1~4 | 0.1~4 | 0.1~3 | 0.1~2.5 | 0.1~2.5 | |

| Tailstock | ||||||||

| Center taper(MT) | (MT) | 3 | 4 | 5 | 6 | Metric 80# | Metric 80# | |

| Quill travel | mm | 25 | 30 | 30 | 70 | 70 | 70 | |

| Motor | ||||||||

Wheelhead motor power | kW | 3 | 11 | 11 | 15 | 22 | 22 | |

| Workhead motor power | kW | 0.25/0.37 | 1.5 | 2.2 | 7.5 | 15 | 15 | |

| Machining accuracy | ||||||||

| Roundness | μm | 2 | 3 | 3(1500)5(2000,3000) | 3(1500)5(2000,300,4000) | 5 | 5 | |

| Cylindricity | μm | 5 | 5 | 6°(1500)5°(2000)3°(3000) | 8(1500)10(2000,3000) 15(4000) | 10(2000,3000)15(4000 5000) | 10(3000)15(400,5000) | |

| Roughness | μm | Ra0.2 | Ra0.2 | Ra0.2(1500) Ra0.32(2000,3000) | Ra0.32 | Ra0.32 | Ra0.32 | |

| Machine | ||||||||

| Gross weight | t. | 2.4(500)2.9(750) | 4.6(1000)5.1(1500) | 5.1(1500)5.7(2000) 7.1(3000) | 11(1500)11(2000)13(3000) 17(4000) | 18(2000) 22(3000) 23(4000)25(5000) | 22(3000) 23(4000)26(5000) | |

| packing dimension | cm | 92x145x205500) | 326x190x205(1000) | 426x190x205(1500) | 543×225×210(1500) | 695x242x226(2000) | 890x260x230(3000) | |

| 530x190x205(2000) | 583×225×210(2000) | 890x242x226(3000) | 1100x260x230(4000) | |||||

| 213×145×205(750) | 426x190x205(1500) | 730x190x205(3000) | 796×225×210(3000) | 1100x242x226(4000) | 1270x260x230(5000) | |||

| 996x225x210(4000) | 1270x242x226(5000) | |||||||

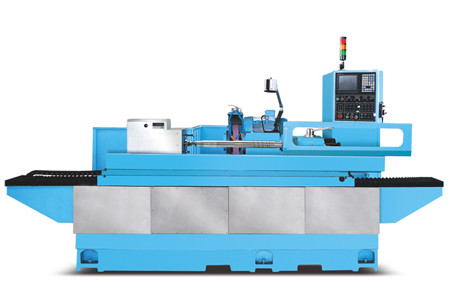

Product Introduction

G1320 G1332 G1332A G1350A G1363 G1380A cylindrical grinders use electrical and hydraulic interlocking mechanisms with various moving parts, which are safe and reliable to operate. It is suitable for grinding IT6-IT5 precision cylindrical or conical rotary workpieces. It is suitable for single-piece and batch production workshops.

Product Features :

- The horizontal feed of wheelhead is driven by hydraulic pressure to realize micro automatic periodic feed and fast advance and regress.Also can do manually rough fine feeding.

- G1350, G1450, G1363 series table and wheelhead guide rail adopt static guide rail, low speed motion is stable.

- G1350, G1450, G1363 series wheelhead with high rigid spindle, high rotary precision, good rigidity. The workhead adopts frequency converter to realize stepless speed regulation.

- Universal workhead can be adjusted at any Angle within 90 degrees counterclockwise to adapt to chuck grinding internal and external conical workpiece.

Advantages

Continuous Innovation

High-tech enterprises, with a number of mature technical teams, annual research and development funds of 2 million, annual research and development of more than 12 new products, 20 national patent technology, continuous innovation.

6S Workshop Standard

36000 ㎡ workshop, 6S workshop standard, workshop through the ISO9001 quality system certification, with complete production equipment, products leave the factory after raw material inspection, process inspection, finished product inspection, products in line with GB and CE standard certification.

Self-built the Factory

Self-built the factory, through the whole industry chain, perfect casting factory, sheet metal factory, CNC machining center, cutting center, processing plant, accessories, the whole process of independent design and development, further reduce the cost, guarantee quality and improve the cost performance.

Our parnters