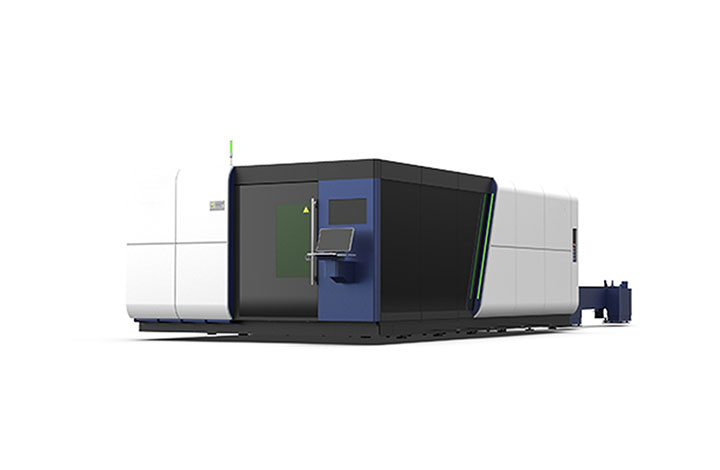

Description

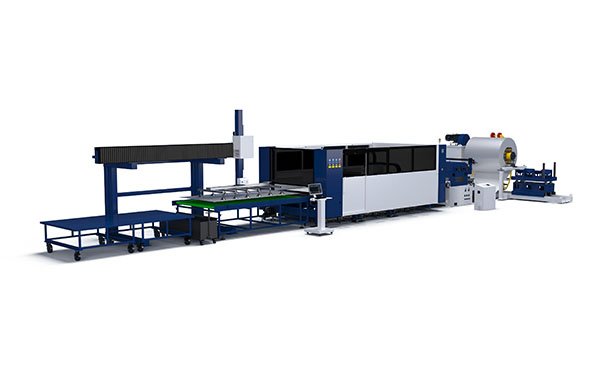

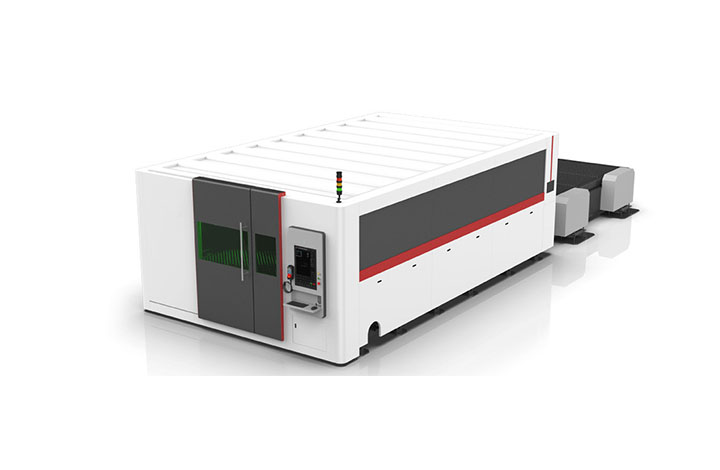

CLGD series fiber laser cutting machine is designed to provide an ultimate efficient ,reliable and smart sheet metal cutting solution, up to 60kW laser cutting capacity, 300m/min linkage dynamic performance, all new reducer, brand new strong machine bed, which greatly improve your comprehensive production efficiency and achieve a further new manufacturing efficiency with our automation solution.Peak dynamics and powerful performance,engineered to accelerate your high-speed growth.

Technical Data

| Model | CLGD4020 |

| Power | 6kW-60kW |

| Processing format (L*W) | 4064mm*2040mm |

| X/Y-axis positioning accuracy | ±0.01mm/m |

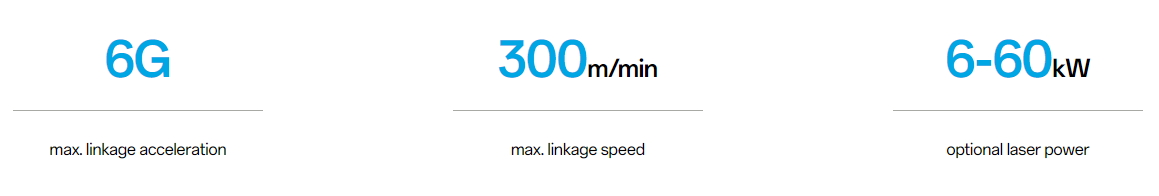

| X/Y-axis repositioning accuracy | 300m/min |

| Max. Linkage Acceleration | 6G |

Character

Ultimate dynamics and efficiency

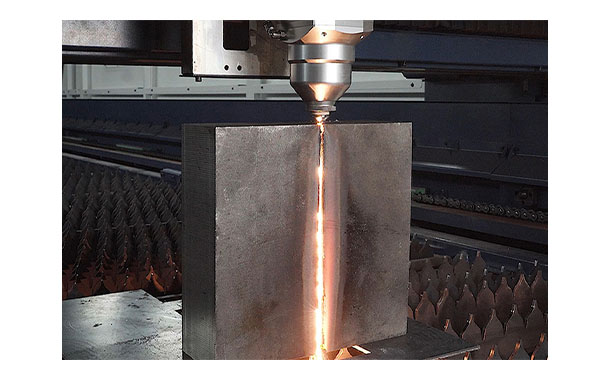

Advanced thick sheet fiber cutting

100mm CS 0.5m/min

The GLCD series offers a selection of laser cutting heads ranging from 6 to 60 kW. Enhanced laser power allows for rapid cutting of thick sheet metal, optimizing speed and efficiency in demanding applications.

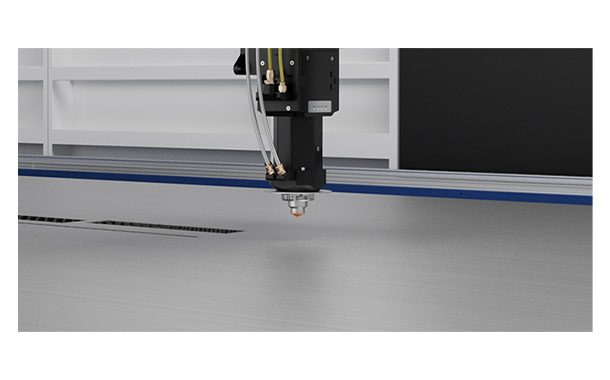

Intelligent visual edge detection

Visual edge detection achieves a 50% improvement in efficiency over traditional capacitive methods.

Intelligent edge patrol: advanced edge inspection capabilities extend to plates with irregular shapes, ensuring thorough quality control.

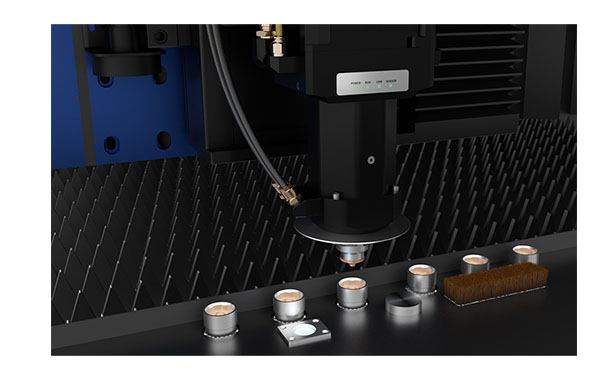

Optimal component maintenance

Maintaining the nozzle and lens in peak condition is crucial for reliable operations and superior part quality.

- Smart nozzle cleaning: effectively removes rust and slag to enhance performance.

- Automatic nozzle replacement: streamlines the cutting process by automatically changing nozzles as required by the task.

- Nozzle life detection: monitors nozzle wear and predicts lifespan based on current surface condition, providing actionable insights to operators

Visual residual material management

- Capture and analyze: automatically photographs leftover plates, enhancing material use through intelligent analysis.

- Seamless integration: instantly generates new, usable plate layouts upon import for streamlined operations.

- Resource maximization: strategically arranges cuts on remaining plates, significantly reducing waste and boosting operational efficiency.

Ultra-stable lathe bed design

Engineered for precision and high-accuracy cutting, this robust structure supports heavy sheet metal and high-power lasers, delivering superior cutting quality and performance.

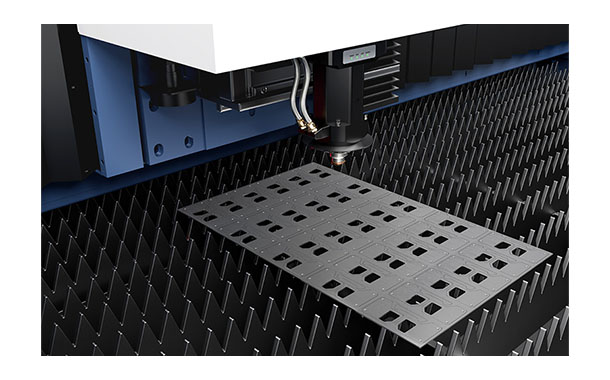

High-precision motion system

Engineered for speed and accuracy, this system consistently positions sheet metal optimally for cutting, delivering unparalleled quality in finished parts.

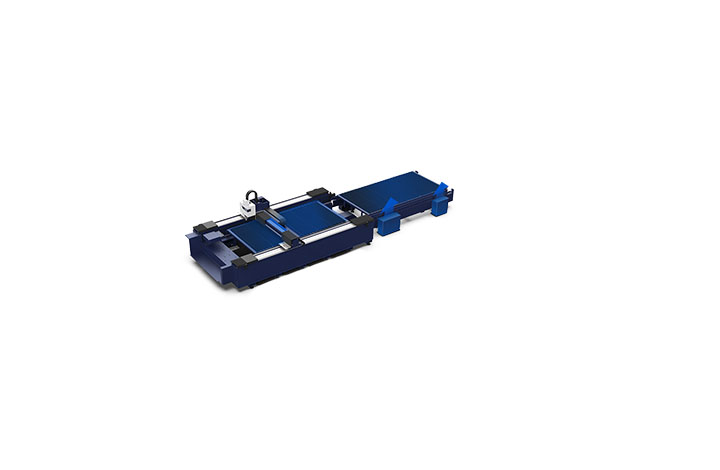

Lift your productivity:hydraulic lifting exchange system

Our advanced hydraulic lifting exchange system features a renowned german-brand hydraulic station,ensuring stability and reliability throughout the process.

The single-table exchange design brings the worktable closer to the exhaust port, enhancing ventilation efficiency for cleaner operations.

This system eliminates the need for a high and low worktable differentiation, allowing the Z-axis cutting head to maintain a consistent position without excessive downward movement. This feature ensures the rigidity and stability of the Z-axis components, especially during high-speed cutting, resulting in precise and reliable performance.

Experience seamless transitions and enhanced cutting efficiency with our hydraulic lifting exchange system, designed to optimize your workflow and ensure superior cutting quality.

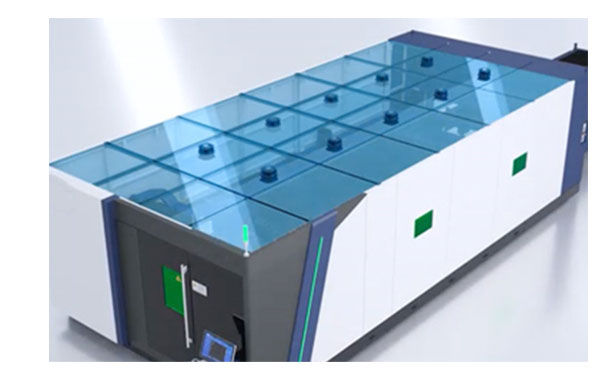

Standard-equipped roof

A standard-equipped roof that effectively contains dust, debris, and airborne particles during machine operations. This containment enhances air quality within the facility and minimizes the spread of particulates, protecting other equipment and products from contamination.

8-zone dust blowing system

The CLGD series offers a selection of laser cutting heads ranging from 6 to 60 kw. Enhanced laser power allows for rapid cutting of thick sheet metal, optimizing speed and efficiency in demanding applications.

Human impact safety protection

The CLGD series equipped with human impact safety protection, the machine will automatically stop if a beam detects any human contact, ensuring a safe working environment.

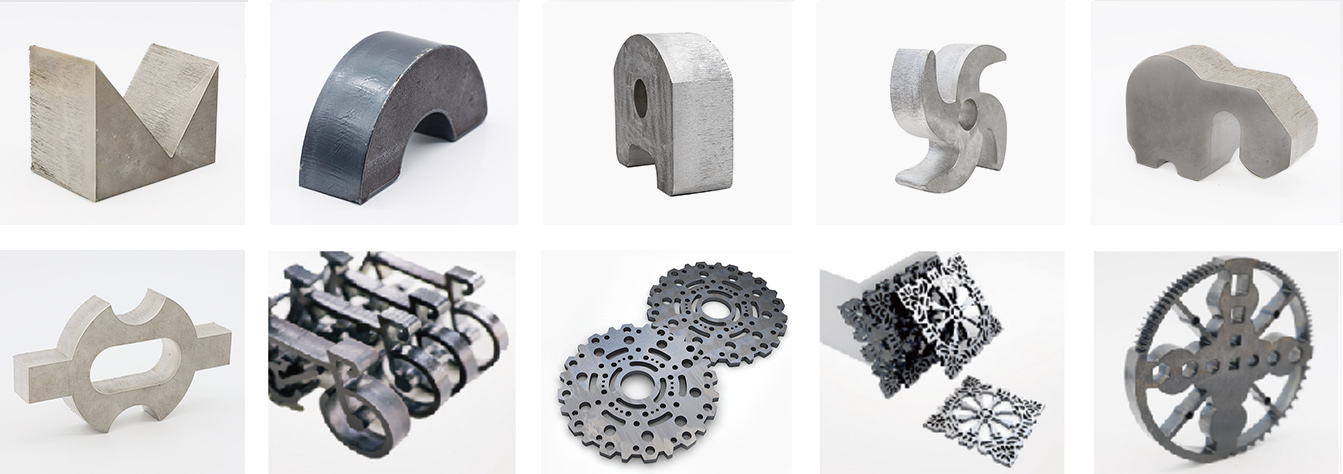

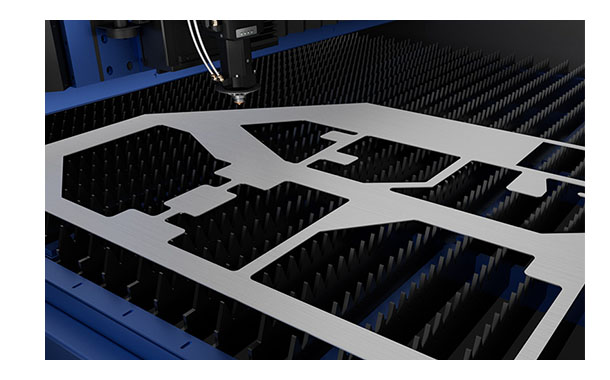

Cut samples