Description

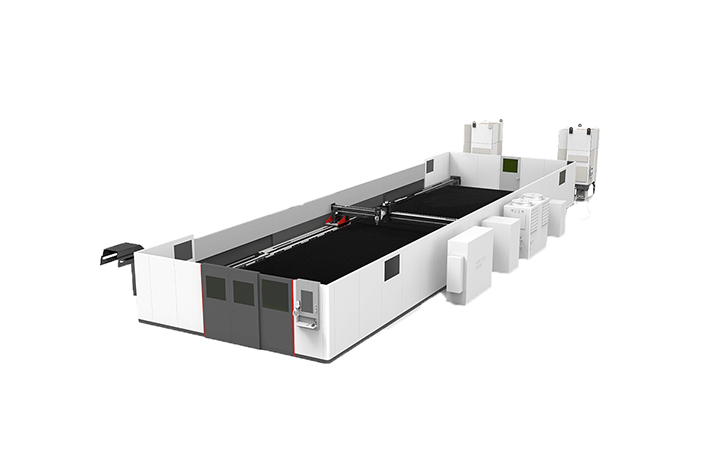

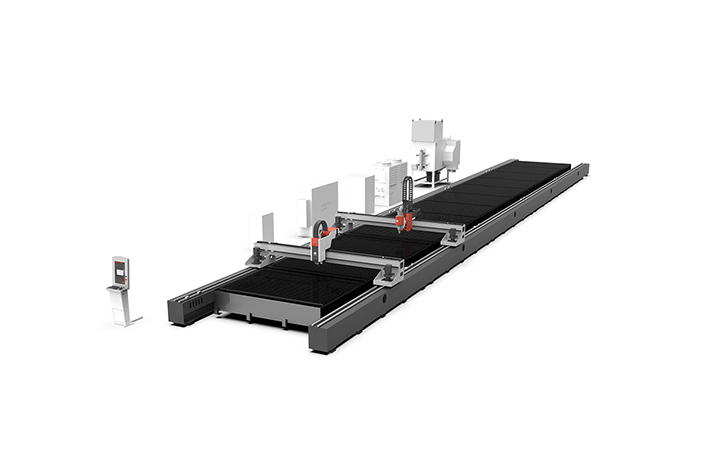

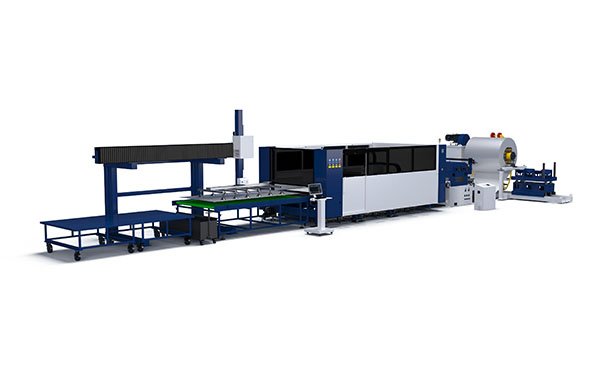

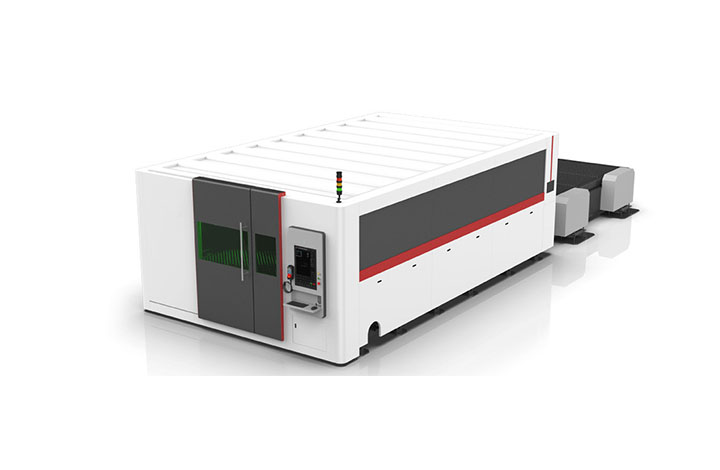

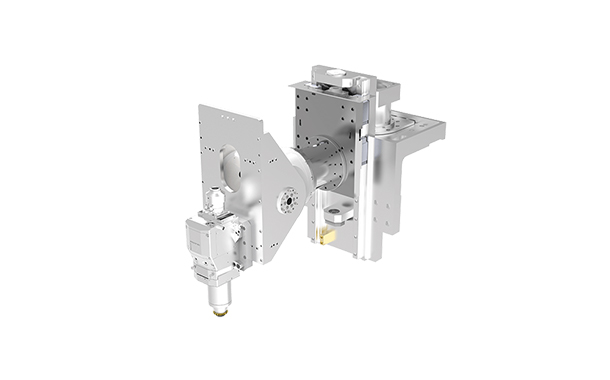

LUMA series bevel laser cutting product have the characteristics of ultra-high power, ultra-large-format (processing format can be customized) high-speed, high-precision, high-stability, and can be used for bevel cutting. This product has good openness and is easy to access the production line and production management system. It is widely used in construction machinery, ships and automobile manufacturing, bridge steel towers and other industries to solve the needs of one-time cutting and bevel cutting of super large plates and workpieces.

Technical Data

| MODEL | LUMA8301 | LUMA1301 | LUMA1303 | LUMA2303 |

| Laser Power | 6000-60000 W | |||

| Control System | SIMENS 840D SL,FARLEY | |||

| Vertical Cutting | Sheet metal:2D cutting and marking | |||

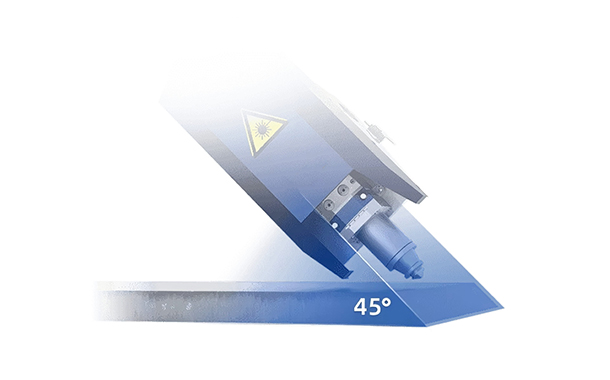

| Bevel Cutting | CS SS AL:V/Y/X/K bevel cutting within±45 degrees | |||

| Processing Capability | ||||

| Cutting Thickness:CS(O2) | Vertically cut MAX:60mm | Vertically cut MAX:60mm Bevel cutting MAX:30mm | ||

| Cutting Thickness:SS(N2) | Vertically cut MAX:60mm | Vertically cut MAX:60mm Bevel cutting MAX:25mm | ||

| Cutting Thickness:AL(N2) | Verticaly cut MAX:60mm | Vertically cut MAX:60mm Bevel cutting MAX:20mm | ||

| Processing Format And Working Range | ||||

| Processing Width | 8000*3000mm | 12000*3500mm | 18000*3000mm | 25000*3500mm |

| K-bevel Processing Width | NA | 17000*2500mm | 24000*3000mm | |

| Route of X-axis | 8100mm | 12100mm | 18100mm | 25100mm |

| Route of Y-axis | 3050mm | 3550mm | 3050mm | 3550mm |

| Route Z- | 150mm | 150mm | 300mm | 300mm |

| Accuracy | ||||

| Positioning accuracy of Xaxis | 0.1mm/10m (≤10m),0.2mm/full length | |||

| Positioning accuracy of Y axis | 0.05mm | |||

| Repeated Positioning accuracy of X axis | 0.05mm/10m(≤10m),0.1mm/full length | |||

| Positioning accuracy of Xaxis | 0.03mm | |||

| Velocity | ||||

| Max Acceleration | 1G | |||

| X/Y Axis Max Positioning Speed | 60m/min | |||

| X/Y Axis Max Positioning Con-speed | 84m/min | |||

Character

Lighweight beam, high efficiency work

With a maximum acceleration of 1G and a maximum speed of 80m/min in a single axis, the machine can achieve higher acceleration and speed.

Smooth and flat cutting surface,

Achieving any shape of bevel cutting at will

Reduce the process, allowing for a maximum 45-degree range of different shapes and bevel angles at one time. Reduce material waste and operating costs.

Energy saving and consumption reduction,

offering greater economic and environmental benefits.

Box beams are designed in a modular,segmented format to minimize material usage

Lightweight bed allows for easy installation and significant time savings

Integrated air extraction, more space-efficient setup and highly effective dust removal

0-45°bevel cutting, including V bevels, X bevels, Y bevels etc.

Cut samples

Application