Technical Data

| Items | MK1060 | MK200 | MK400 | MK500 | MK11250 |

| Plunge-feeding Grinding Diameter | 5-60mm | 5-100mm | 5-200mm | 5-200mm | 10-250mm |

| Max grinding length(Plunge-feeding) | 195mm | 190mm | 390mm | 490mm | 590mm |

| Through-feeding Grinding Diameter | 5-60mm | 5-100mm | 5-200mm | 5-200mm | 10-250mm |

| Grinding wheel Specification(mm) | 500*200(250)*305 | 500*200(250)*305 | 600*400*305 | 600*500*305 | 600*600*305 |

| Regulating wheel specification(mm) | 350*200*127 | 350*200(300)*203 | 350*400*203 | 350*500*203 | 350*600*203 |

| Grinding wheel speed | 1318r/min | 1100r/min | 1100r/min | 1100r/min | 1110r/min |

| Regulating wheel speed(stepless) | 10-200 r/min | 10-200r/min | 10-200r/min | 10-2001/min | 10-200r/min |

| Regulating wheel Swiveling angle(Vertical) | -1°- +5° | -2°~5° | -2°~5° | -2°~5° | -2°- +4° |

| Regulating wheel Swiveling angle(Horizontal) | 0°- +5° | -1°~ 3° | -1°~ 3° | -1°~ 3° | 0°- +3° |

| Grinding wheel frame min feed amount | 0.001mm | 0.001mm | 0.001mm | 0.001mm | 0.001mm |

| Regulating wheel frame min feed amount | 0.001mm | 0.001mm | 0.001mm | 0.001mm | 0.01mm |

| Grinding wheel dresser feed amount/division | 0.01mm | 0.001mm | 0.001mm | 0.001mm | 0.01mm |

| Regulating wheel dresser feed amount/division | 0.01mm | 0.01mm | 0.01mm | 0.01mm | 0.01mm |

| Height from centerline of gri.wheel & reg.wheel to workrest | 250mm | 200mm | 200mm | 200mm | 290mm |

| Grinding wheel motor (KW) | 15KW | 22kW | 30kW | 37kW | 45KW |

| Regulating wheel motor (KW) | 1.5KW | 3kW | 3kW | 3kW | 3KW |

| Power supply | 3N 380V 50HZ | 3N 50HZ 380V | 3N 50HZ 330V | 3N 50HZ 380V | 3N 50HZ 380V |

| Machine dimension in mm (L*W*H) | 2050*1680*1380 | 3200*1785*1800 | 3300*1780*1900 | 3400*2100*1800 | 3700*1850*1820 |

| Machine weight (Kg) | ≈3200Kg | ≈7500Kg | ≈9000Kg | ≈10000 Kg | ≈ 11000Kg |

| Roundness (mm) | 0.001mm | 0.001mm | 0.001mm | 0.001mm | 0.002mm |

| Cylindricity (mm) | 0.002 mm | 0.0018mm | 0.0018mm | 0.0018mm | 0.005mm |

| Roughness (μm) | Ra0.16μm | Ra0.16μm | Ra0.16μm | Ra0.16μm | Ra0.32μm |

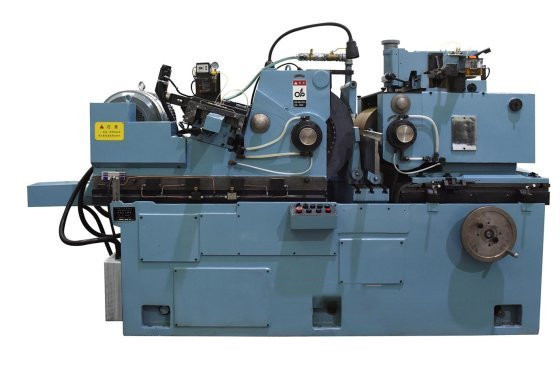

Product Introduction

Through grinding : It is mainly used for grinding cylindrical surfaces of various ring and shaft parts.

Plunge-feed : Hand-cut grinding is carried out on all kinds of stepped, tapered and cylindrical rotating surfaces.

Technical Advantages and Features :

1. High-precision grinding capability: CNC Centerless grinder adopts high-precision guide wheel spindle and grinding wheel spindle design, such as double-row cylindrical roller bearing structure and double support structure, to ensure high rotation accuracy.

2. Strong cutting force and high grinding wheel utilization rate: The grinding wheel width of the centerless grinder is large, such as 600mm wide grinding wheel, which makes the cutting force strong and the grinding wheel utilization rate high.

3. High-efficiency grinding: Due to the wide thickness of the grinding wheel, the grinding allowance of one pass can be increased during the grinding, reducing the number of repeated grindings, thereby improving productivity.

4. Stable bearing capacity: The grinding wheel and guide wheel adopt a double-support hydrodynamic bearing structure, which makes the grinding bearing capacity strong.

5. Automation-friendly layout: The machine tool has a double-sided mobile layout, the bracket is fixed on the bed, the guide wheel frame only makes adjustment movements, the workpiece position remains unchanged, and it is easy to equip various feeding devices, which is convenient for automation.

6. Sensitive movement and vibration resistance: The grinding frame adopts a plastic-coated guide rail structure, which is sensitive to movement, can achieve micro-feeding and has vibration resistance, and the guide rail is not easy to wear.

7. Fine feed control: The feed mechanism adopts a Japanese servo motor to drive a high-rigidity reducer, and drives the ball screw through a coupling to achieve feeding. The minimum feed amount can reach 0.001 mm.

8. Stepless speed regulation and anti-backward drag function: The guide wheel adopts an AC variable frequency stepless speed regulation device, which can not only achieve stepless speed regulation, but also has an anti-backward drag function.

9. Hydraulic drive dresser: The sand and guide wheel dressers are hydraulically driven for reciprocating and stepless speed regulation.

10. Human-machine dialogue operation interface: The operation adopts touch screen human-machine dialogue, with automatic cutting-in grinding program, and feed amount, speed and time are all adjustable.

11. Modular design: The machine tool is modularly designed with beautiful appearance, and users can configure and purchase according to their needs.

12. International quality management system: The ISO9001 international quality management system is adopted to ensure product quality.

13. Wide range of applications: The center-less grinder is suitable for a wide range of applications from tiny nozzle needles to high-precision pump pistons to heavy rail shafts.

Advantage

Continuous Innovation

High-tech enterprises, with a number of mature technical teams, annual research and development funds of 2 million, annual research and development of more than 12 new products, 20 national patent technology, continuous innovation.

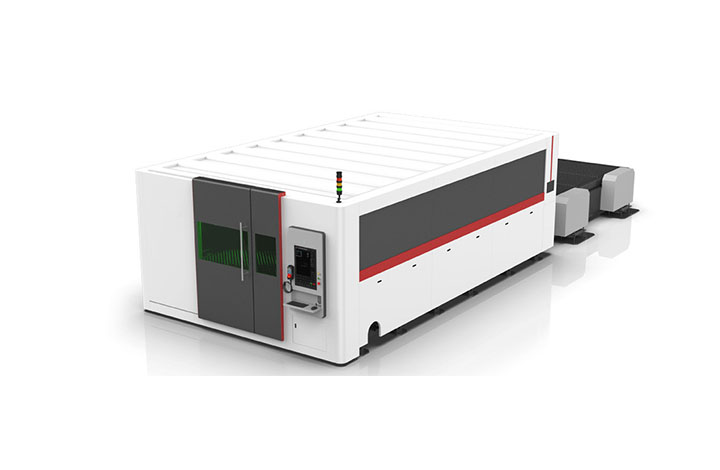

6S Workshop Standard

36000 ㎡ workshop, 6S workshop standard, workshop through the ISO9001 quality system certification, with complete production equipment, products leave the factory after raw material inspection, process inspection, finished product inspection, products in line with GB and CE standard certification.

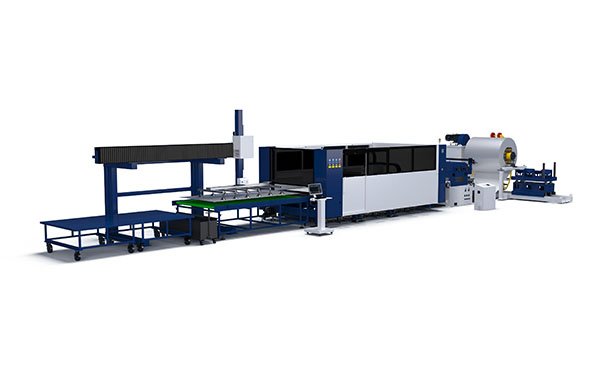

Self-built the Factory

Self-built the factory, through the whole industry chain, perfect casting factory, sheet metal factory, CNC machining center, cutting center, processing plant, accessories, the whole process of independent design and development, further reduce the cost, guarantee quality and improve the cost performance.

Our parnters