Technical Data

| Name | Unit | Machine Models | |||

| HP-VMC855 | HP-VMC1055 | ||||

| Travel | Table travel(X-axis) | mm | 850 | 1050 | |

| Saddle travel(Y-axis) | mm | 500 | 550 | ||

| Spindle box travel(Z-axis) | mm | 500 | 550 | ||

| Distance from spindle nose to table surface | mm | 150-650 | 120-670 | ||

| Distance spindle center to column guide surface | mm | / | 650 | ||

| Table | Table size | mm | 1100*450 | 1200*500 | |

| Table loading | kg | 600 | 800 | ||

| T-SLOT(QTY-Width*Space) | mm | 3-18*125 | 5-18*100 | ||

| Spindle | Motor power (S1/S6) | kW | 11/18.5 | 11/18.5 | |

| Motor torque (S1/S6) (rated/short-time) | N.m | 52.5/118 | 52.5/118 | ||

| Rotary speed | r/min | 50~12000(direct) | 50~12000(direct) | ||

| Spindle diameter | mm | Ф150 | Ф150 | ||

| Spindle tapper | / | BBT40 | BBT40 | ||

| Drive | Motor power X/Y/Z | kW | 3.0/3.0/3.0 | 3.0/3.0/3.0 | |

| Speed | X/Y/Z axis rapid speed | m/min | 48/48/48 | 48/48/48 | |

| Accuracy | Position accuracy(X/Y/Z) | mm | 0.006/0.006/0.006 | 0.006/0.006/0.006 | |

| Repeatability(X/Y/Z) | mm | 0.004/0.004/0.004 | 0.004/0.004/0.004 | ||

| Tool magazine | Tool capacity | T | 30 | 30 | |

| Max. weight | kg | 8 | 8 | ||

| Max. length | mm | 350 | 350 | ||

| Max. allowable torque | Nm | ≤10.19 | ≤10.19 | ||

| Max. diameter(full/adjacent) | mm | Ф80/Ф150 | Ф80/Ф150 | ||

| Others | CNC system | / | FANUC 0i MF PLUS | FANUC 0i MF PLUS | |

| Gas source | Flow | L/min | ≥280(ANR) | ≥280(ANR) | |

| Air pressure | MPa | 0.6-0.8 | 0.6-0.8 | ||

| Equipment capacity | KVA | 25 | 25 | ||

| Machinery size | mm | 3028*2914*2935 | 3148*2926*2935 | ||

| Machine weight(approx.) | kg | 5600 | 6000 | ||

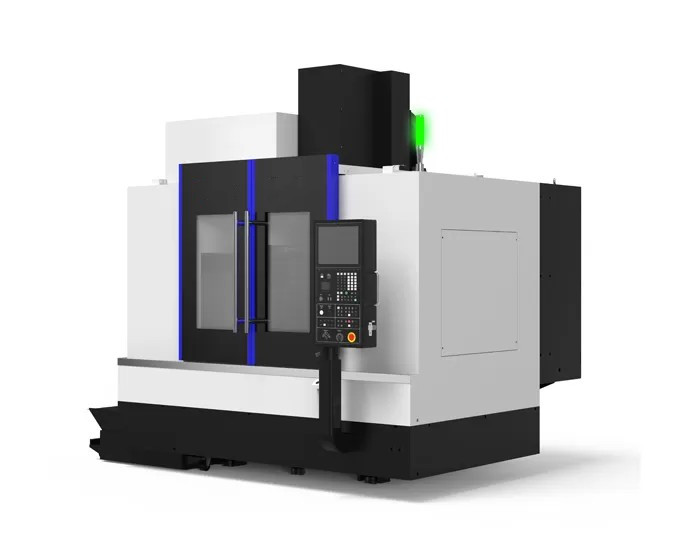

Description

- Full Travel Support Structure

The machine features a T-shaped bed, with the saddle moving left and right on the X-axis and the table moving forward and backward on the Y-axis. The full travel support of the table and saddle eliminates the lateral overhang of traditional C-type vertical machining centers, ensuring better dynamic performance and cutting stability.

- Hollow Cooling Ball Screw

The large-diameter precision ball screw features a hollow cooling system and pre-tension design to reduce thermal deformation, improve machining precision, and extend the screw’s service life.

- Precision High-Speed Spindle Unit

The spindle uses a BBT40-12000r/min direct-drive system with a cooling system to reduce thermal deformation, improve accuracy, and extend bearing life. The spindle front end has a labyrinth seal and air curtain to prevent coolant from entering the bearings, ensuring long-term stability.

- Fully Enclosed Tool Magazine

The fully enclosed tool magazine protects the tools from contamination, keeping them clean. The servo-driven ATC system improves tool change speed, accuracy, and stability, boosting machining efficiency.

Applications

Advantages

Continuous Innovation

High-tech enterprises, with a number of mature technical teams, annual research and development funds of 2 million, annual research and development of more than 12 new products, 20 national patent technology, continuous innovation.

6S Workshop Standard

36000 ㎡ workshop, 6S workshop standard, workshop through the ISO9001 quality system certification, with complete production equipment, products leave the factory after raw material inspection, process inspection, finished product inspection, products in line with GB and CE standard certification.

Self-built the Factory

Self-built the factory, through the whole industry chain, perfect casting factory, sheet metal factory, CNC machining center, cutting center, processing plant, accessories, the whole process of independent design and development, further reduce the cost, guarantee quality and improve the cost performance.

Our partners