Technical Data

| Items | Unit | Machine Models | ||||||

| H-VMC8 | H-VMC10 | H-VMC12 | H-VMC15 | H-VMC18 | ||||

| Travel | Table Travel (X-axis) | mm | 800 | 1000 | 1200 | 1500 | 1800 | |

| Saddle Travel (Y-axis) | mm | 500 | 600 | 700 | 800 | 900 | ||

| Headstock Travel (Z-axis) | mm | 500 | 600 | 600 | 700 | 680 | ||

| Spindle Nose to Table | mm | 130~630 | 180~780 | 150~750 | 170~870 | 160~840 | ||

| Spindle Center to Column | mm | 500 | 600 | 785 | 810 | 950 | ||

| Table | Table Size | mm | 1050×500 | 1300×600 | 1360×700 | 1700×800 | 2000×900 | |

| Table Loading Capacity | kg | 600 | 800 | 1000 | 1500 | 1600 | ||

| T-Slots (Qty-Width×Pitch) | mm | 5-18×90 | 5-18×120 | 5-18×152.5 | 5-22×135 | 5-22×165 | ||

| Spindle | Motor Power (Cont./30min) | kW | 7.5/11 | 7.5/11 | 11/15 | 15/18.5 | 18.5/22 | |

| Speed Range | rpm | 50~8000(Belt-driven) | 50~8000(Belt-driven) | 50~8000(Belt-driven) | 50~8000(Belt-driven) | 50~8000(Belt-driven) | ||

| Spindle Diameter | mm | φ150 | φ150 | φ155 | φ155 | φ190 | ||

| Tool Holder Type | – | BT40 | BT40 | BT50 | BT50 | BT50 | ||

| Pull Stud Type | – | P40T-I(MAS403) | P40T-I(MAS403) | P50T-I(MAS403) | P50T-I(MAS403) | P50T-I(MAS403) | ||

| Speed | Feed Rate Range | mm/min | 1-10000 | 1-10000 | 1-10000 | 1-10000 | 1-10000 | |

| Rapid Traverse Speed(X/Y/Z) | m/min | 16/16/16 | 16/16/16 | 12/12/12 | 12/12/12 | 12/12/12 | ||

| Accuracy | Positioning Accuracy(X/Y/Z) | mm | 0.008 | 0.008 | 0.015 | 0.02 | 0.024 | |

| Repeatability(X/Y/Z) | mm | 0.005 | 0.005 | 0.008 | 0.01 | 0.012 | ||

| Other | CNC System | – | Mitsubishi M80VA | Mitsubishi M80VA | Mitsubishi M80VA | Mitsubishi M80VA | Mitsubishi M80VA | |

| Air Supply | Flow | L/min | ≥280(ANR) | ≥280(ANR) | ≥280(ANR) | ≥280(ANR) | ≥280(ANR) | |

| Pressure | MPa | 0.6-0.8 | 0.6-0.8 | 0.6-0.8 | 0.6-0.8 | 0.6-0.8 | ||

| Power Requirement | kVA | 25 | 25 | 30 | 35 | 45 | ||

| Coolant Tank Capacity | L | 200 | 350 | 350 | 350 | 400 | ||

| Machine Dimensions | mm | 2710×2320×2740 (X/Y/Z axis directions) | 3380×2610×2850 (X/Y/Z axis directions) | 3650×3020×2900 (X/Y/Z axis directions) | 4370×3200×3500 (X/Y/Z axis directions) | 4850×3500×3500 (X/Y/Z axis directions) | ||

| Machine Weight(approx.) | kg | 4950 | 6900 | 9400 | 11300 | 14750 | ||

Description

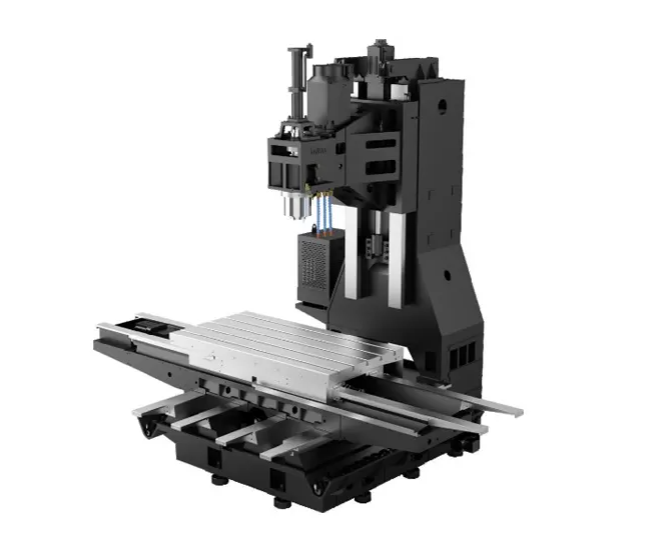

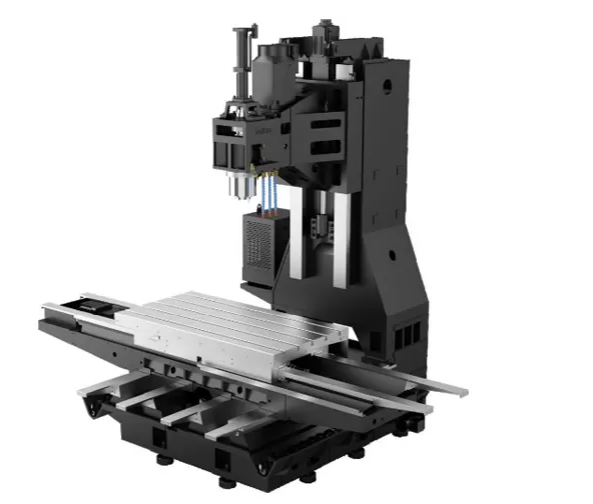

Machine Structure

Fixed column, cross-type sliding table: This design provides solid support and is suitable for high-speed cutting.

Large, stable base, high-rigidity, wide-span A-shaped column: Reduces vibration and deformation, ensuring high rigidity.

High-quality resin sand molding, high-strength cast iron: Ensures the machine’s rigidity and stability, reduces deformation, and maintains long-term precision.

Z-axis Counterweight

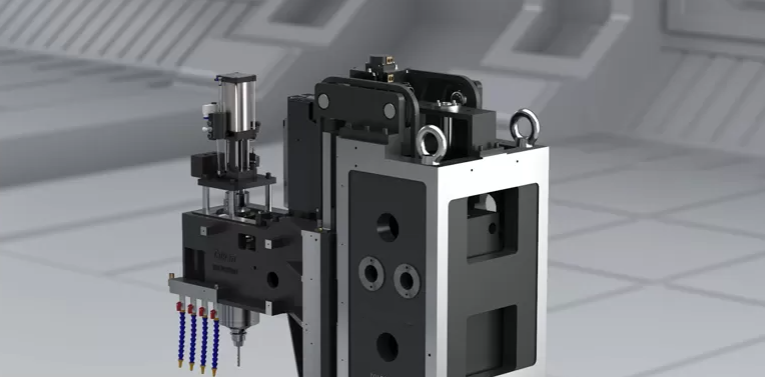

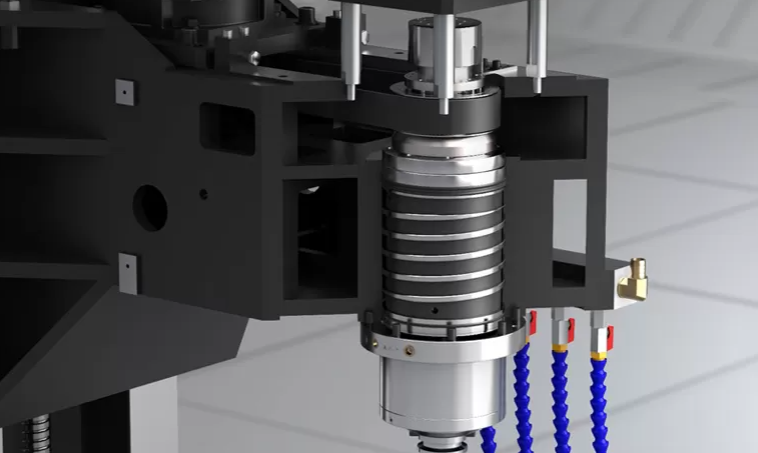

Spindle

High-speed spindle (BT40-12000r/min): Equipped with a direct connection head, the spindle front features a labyrinth design with an air curtain protection to prevent coolant from entering the spindle bearings.

Three-Axis Box Guideway

Applications

Advantages

Continuous Innovation

High-tech enterprises, with a number of mature technical teams, annual research and development funds of 2 million, annual research and development of more than 12 new products, 20 national patent technology, continuous innovation.

6S Workshop Standard

36000 ㎡ workshop, 6S workshop standard, workshop through the ISO9001 quality system certification, with complete production equipment, products leave the factory after raw material inspection, process inspection, finished product inspection, products in line with GB and CE standard certification.

Self-built the Factory

Self-built the factory, through the whole industry chain, perfect casting factory, sheet metal factory, CNC machining center, cutting center, processing plant, accessories, the whole process of independent design and development, further reduce the cost, guarantee quality and improve the cost performance.

Our partners