Technical Data

| Items | Unit | Machine Model:T-VMC1285W | ||

| Travel | Table travel (X axis) | mm | 1200 | |

| Saddle travel (Y axis) | mm | 850 | ||

| Headstock travel (Z axis) | mm | 700 | ||

| Distance from spindle nose to table surface | mm | 80-780 | ||

| Distance from spindle center to column guide surface | mm | 921 | ||

| Worktable | Table size | mm | 1300×850 | |

| Max. load (even load-bearing) | kg | 1000 | ||

| T-slot (number of slots – slot width * spacing) | mm | 7-18×125 | ||

| Spindle | Motor power (rated/short time) | kW | 11/15 | |

| Motor torque (rated/short time) | N.m | 52.5/118 | ||

| Speed range | r/min | 50~12000 (Directly coupled) | ||

| Spindle diameter | mm | φ150 | ||

| Spindle taper | / | BT40 | ||

| Rivet specifications | / | P40T-I(MAS403) | ||

| Speed | Cutting feed speed range | mm/min | 1-10000 | |

| X/Y/Z axis rapid traverse speed | m/min | 24/24/16 | ||

| Accuracy | Positioning accuracy (X/Y/Z) | mm | 0.01 GB/T18400.4(Full travel) | |

| Repeatability (X/Y/Z) | mm | 0.007 GB/T18400.4(Full travel) | ||

| Tool magazine | Tool capacity | pcs | 24 | |

| Max. tool weight | kg | 7 | ||

| Max. tool length | mm | 250 | ||

| Max. tool diameter (full /adjacent empty) | mm | Φ75/Φ150 | ||

| Others | CNC system | / | FANUC 0I-MF | |

| Air source | Flow | L/min | ≥280(ANR) | |

| Air pressure | MPa | 0.6~0.8 | ||

| Equipment capacity | KVA | 40 | ||

| Coolant tank capacity | L | 350 | ||

| Machine size | mm | 3000×4080×3200 (Corresponding to X*Y*Z axis) | ||

| Weight (approx.) | Kg | 9200 | ||

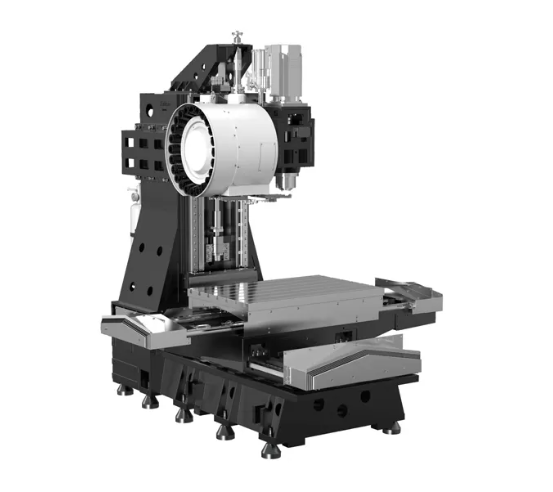

Description

The workpiece can automatically and continuously perform multiple machining operations including milling, drilling, boring, reaming, counterboring, spot facing and tapping in a single setup. Featuring long Y-axis stroke design, this system is particularly suitable for processing square or circular workpieces, and has been widely applied in 26-inch new energy vehicle wheel hub manufacturing adopting casting/forging processes and semi-solid die forging technology.

Machine Structure and Design

Designed specifically for machining automobile wheel hubs up to 26 inches, with a wide stroke, fast processing speed, high rigidity, and precision.

Fixed column cross-slide structure, stable base, and large-span A-frame columns ensure no vibration or deformation during high-speed cutting.

Optimized Z-Axis

The Z-axis features nitrogen balancing and a six-block design, ensuring smooth high-speed movement and making it ideal for high-gloss surface machining.

Spindle

The machine features a high-speed spindle unit from Taikan, equipped with a BT40-12000 rpm direct connection head. The spindle front uses a labyrinth design with an air curtain protection, preventing cutting fluids from entering the spindle bearings.

Tool Magazine

The machine is equipped with a 24-pocket arm-type tool magazine from Taikan, known for its reliable quality and stable performance.

Applications

Advantages

Continuous Innovation

High-tech enterprises, with a number of mature technical teams, annual research and development funds of 2 million, annual research and development of more than 12 new products, 20 national patent technology, continuous innovation.

6S Workshop Standard

36000 ㎡ workshop, 6S workshop standard, workshop through the ISO9001 quality system certification, with complete production equipment, products leave the factory after raw material inspection, process inspection, finished product inspection, products in line with GB and CE standard certification.

Self-built the Factory

Self-built the factory, through the whole industry chain, perfect casting factory, sheet metal factory, CNC machining center, cutting center, processing plant, accessories, the whole process of independent design and development, further reduce the cost, guarantee quality and improve the cost performance.

Our partners