Technical Data

| Items | Unit | Machine Models | Remarks | |||||

| VMC-V6 | VMC-V16 | VMC-V18 | VMC-V20 | |||||

| Travel | Table travel (X axis) | mm | 600 | 1600 | 1800 | 2000 | ||

| Saddle travel (Y axis) | mm | 390 | 650 | 650 | 650 | |||

| Headstock travel (Z axis) | mm | 450 | 590 | 590 | 590 | |||

| Distance from spindle nose to table surface | mm | 190~640 | 100~690 | 100~690 | 100~690 | |||

| Distance from spindle center to column guide surface | mm | 455 | 707 | 707 | 707 | |||

| Worktable | Table size | mm | 700*400 | 1700*650 | 1700*650 | 2000*650 | ||

| Max. load (even load-bearing) | kg | 250 | 800 | 800 | 800 | |||

| T-slot (number of slots – slot width * spacing) | mm | 3-18*125 | 5-18*125 | 5-18*125 | 5-18*125 | |||

| Spindle | Motor power (rated/short time) | kW | 3.7/5.5 | 7.5/11 | 7.5/11 | 7.5/11 | ||

| Motor torque (rated/short time) | N.m | 23.6/35 | 35.8/95.5 | 35.8/95.5 | 35.8/95.5 | |||

| Speed range | r/min | 20~12000 (Directly coupled) | 20~12000 (Directly coupled) | 20~12000 (Directly coupled) | 20~12000 (Directly coupled) | |||

| Spindle diameter | mm | φ120 | φ150 | φ150 | φ150 | |||

| Spindle taper | / | BT40 | BT40 | BT40 | BT40 | |||

| Rivet specifications | / | P40T-I(MAS403) | P40T-I(MAS403) | P40T-I(MAS403) | P40T-I(MAS403) | |||

| Speed | Cutting feed speed range | mm/min | 1-10000 | 1-15000 | 1-15000 | 1-15000 | ||

| X/Y/Z axis rapid traverse speed | m/min | 48/48/48 | 30/36/36 | 30/36/36 | 27/36/36 | |||

| Accuracy | Positioning accuracy (X/Y/Z) | mm | 0.006 | 0.015 | 0.015 | 0.015 | GB/T18400.4 (Full travel) | |

| Repeatability (X/Y/Z) | mm | 0.004 | 0.008 | 0.008 | 0.008 | GB/T18400.4 (Full travel) | ||

| Tool magazine | Tool capacity | pcs | 24 | 24 | 24 | 24 | ||

| Max. tool weight | kg | 7 | 7 | 7 | 7 | |||

| Max. tool length | mm | 250 | 250 | 250 | 250 | |||

| Max. tool diameter (full /adjacent empty) | mm | Φ75/Φ150 | Φ75/Φ150 | Φ75/Φ150 | Φ75/Φ150 | |||

| Others | Z-axis counterweight | |||||||

| CNC system | / | Mitsubishi M80VB | Mitsubishi M80VB | Mitsubishi M80VB | Mitsubishi M80VB | |||

| Air source | Flow | L/min | ≥280(ANR) | ≥280(ANR) | ≥280(ANR) | ≥280(ANR) | ||

| Air pressure | MPa | 0.6~0.8 | 0.6~0.8 | 0.6~0.8 | 0.6~0.8 | |||

| Equipment capacity | KVA | 15 | 25 | 25 | 25 | |||

| Coolant tank capacity | L | 145 | 400 | 400 | 400 | |||

| Machine size | mm | 2100×2580×2670 | 4000*3900(including steps)*2950 | 4000*3900(including steps)*2950 | 4000*3900(including steps)*2950 | Corresponding to X*Y*Z axis | ||

| Weight (approx.) | Kg | 3500 | 7850 | 8160 | 8450 | |||

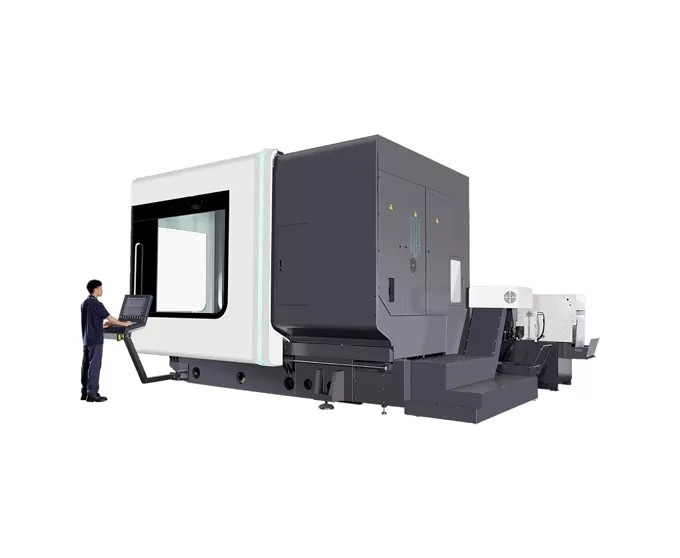

Description

The machine tool is suitable for the multi-variety, small-batch processing of complex parts such as medium and small-sized box-shaped components, plates, disks, valves, housings, and molds. It is widely used in industries such as precision parts, 5G products, hardware, automotive parts, and medical devices.

Character

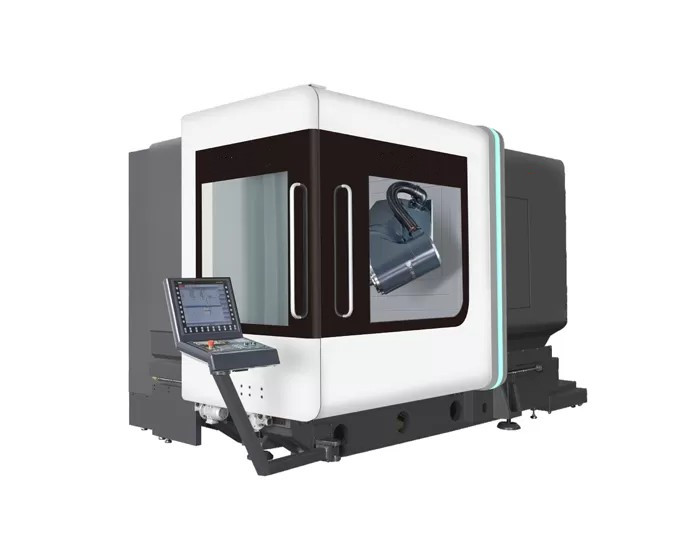

High Stability Base

The base structure, designed through digital analysis and special design, features an oversized span with six-point support, significantly enhancing the machine’s rigidity and vibration resistance, ensuring stability throughout the machining process. The main large components are cast from high-strength cast iron materials using high-quality resin sand molding, providing excellent rigidity and precision stability for the machine.

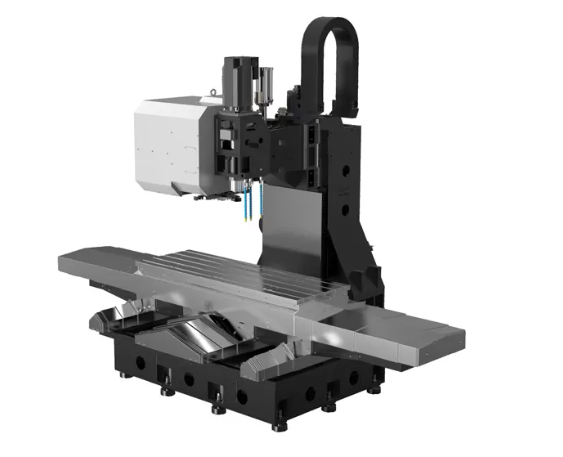

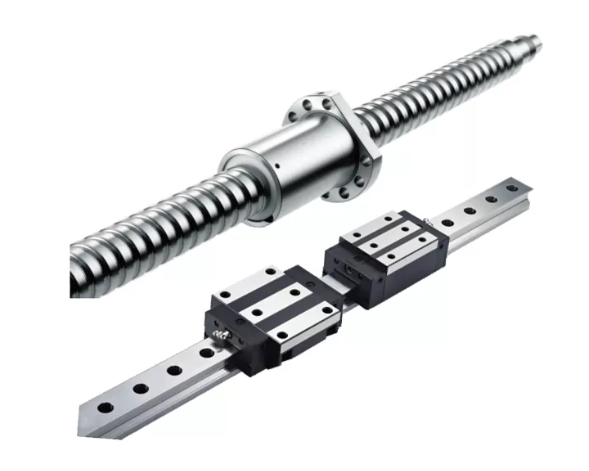

High-Precision Feed Axes

All three axes are equipped with ball linear guides, offering high rigidity, low friction, and strong load-bearing capacity.

The Z-axis uses a brake-type servo motor combined with a counterbalance-free design, improving drive performance and achieving optimal surface precision during 3D machining.

Full stroke motion accuracy is laser-calibrated and compensated, ensuring high precision and stable calibration results.

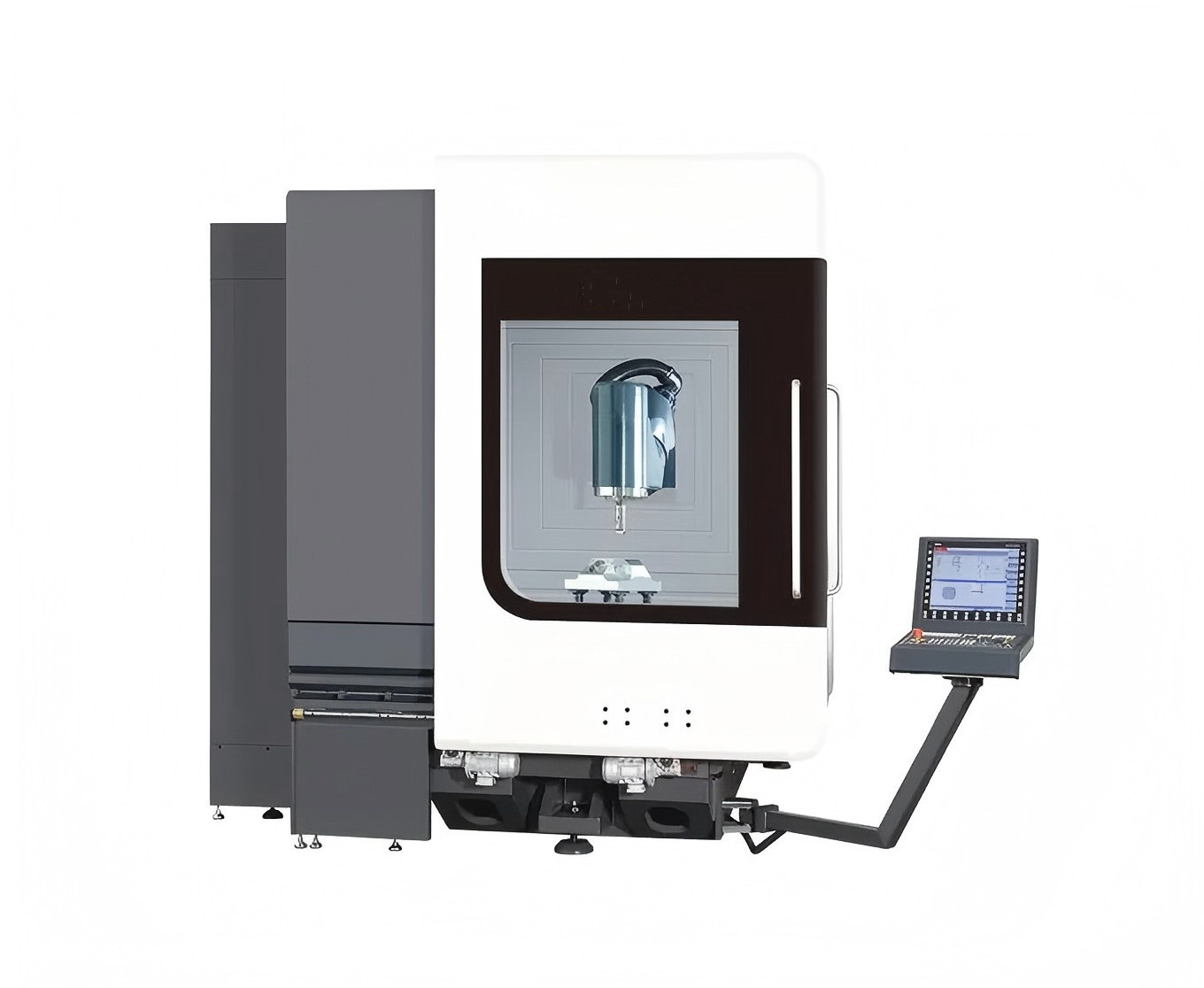

High-Speed Spindle Unit

The spindle uses a BT40-12000r/min direct-drive spindle head and is equipped with an automatic constant-temperature circulating oil cooling system, effectively reducing temperature rise and thermal deformation, while maintaining high machining precision.

Samples