Technical Data

| Item | Unit | Machine Model:EC-400E |

| orkbench | Table size (mm) | 400*400 |

| Distance from table to spindle nose (mm) | 110~260 | |

| Maximum load-bearing weight (Kg) | 100 | |

| journey | X-direction travel (mm) | 400 |

| Travel in Y direction (mm) | 400 | |

| Z travel (mm) | 150 | |

| Spindle | Spindle power (Kw) | 4 |

| Spindle maximum speed (rpm) | 40 000 | |

| Spindle diameter (mm) | φ80 | |

| Spindle tool change method | Pneumatic tool changer | |

| Shank form | ISO 20 | |

| Feed rate | Maximum dry run feed speed (m/min) | 15 |

| Maximum cutting feed rate (m/min) | 8 | |

| Machine tool accuracy | Positioning accuracy: X/Y/Z (mm) | 0.005 |

| Repeated positioning accuracy: X/Y/Z (mm) | 0.004 | |

| Tool magazine | Tool magazine capacity | 10T |

| Tool magazine form | Semi-umbrella servo tool magazine | |

| power source | Air pressure (Mpa) | ≥0.6 |

| Electricity demand (Kw) | 8.5 | |

| Other parameters | Dimensions (front and rear *left and right * up and down mm) | 1550*1450*2082 |

| Weight (Approx. weight: Kg) | 1700 | |

| Whether to configure network transmission and monitoring functions | Have | |

| Whether to configure the tool setter | Have |

Description

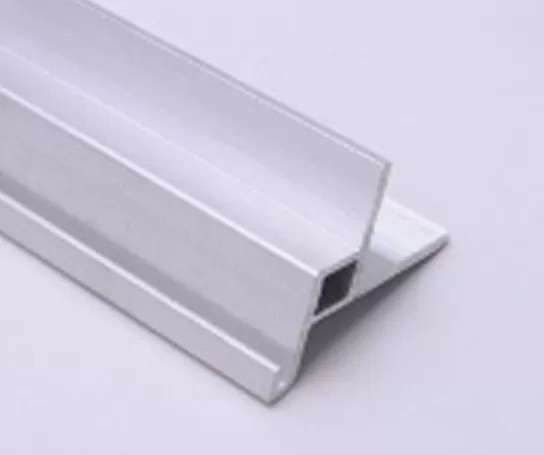

It is ideal for drilling and fine shaping of non-metal materials such as mobile phone glass and composite decorative parts.

- CNC System

Equipped with the high-performance CNC system for reliable control and precision.

- Cast Iron Bed and Beam

The machine’s cast iron bed and beam provide high rigidity, ensuring stable machining performance.

- High-Precision Electric Spindle

Standard configuration includes a high-precision electric spindle for superior accuracy in machining tasks.

- 10-Tool Servo Tool Magazine

Comes with a 10-tool servo-driven tool magazine to enhance machining efficiency.

Applications

Advantages

Continuous Innovation

High-tech enterprises, with a number of mature technical teams, annual research and development funds of 2 million, annual research and development of more than 12 new products, 20 national patent technology, continuous innovation.

6S Workshop Standard

36000 ㎡ workshop, 6S workshop standard, workshop through the ISO9001 quality system certification, with complete production equipment, products leave the factory after raw material inspection, process inspection, finished product inspection, products in line with GB and CE standard certification.

Self-built the Factory

Self-built the factory, through the whole industry chain, perfect casting factory, sheet metal factory, CNC machining center, cutting center, processing plant, accessories, the whole process of independent design and development, further reduce the cost, guarantee quality and improve the cost performance.

Our partners