Technical Data

| Name | Unit | Machine Model : HMC-63 | Remark | ||

| Travel | X/Y/Z | mm | 1050/800/1000 | ||

| Distance from spindle end face to table center | mm | 150-1150 | |||

| Distance from the spindle to table surface | mm | 120-920 | |||

| Max. workpiece size | mm | φ1000×1000 | |||

| Table | Size | mm | 630*630 | ||

| Max. load | kg | 1200 | |||

| Center hole size | mm | φ80H7 | |||

| Screw holes | mm | M16(125×125) | |||

| Min. setting unit | ° | 0.001 | |||

| Spindle | Power (S1/S6 15%) | kW | 28/42 | ||

| Torque (S1/S6 15%) | Nm | 334/630 | |||

| Speed | r/min | 10000 | |||

| Taper | – | BT50 | |||

| Speed | X, Y, Z axis rapid traverse | m/min | 48/48/48 | ||

| Accuracy | Positioning accuracy (X/Y/Z) | mm | X/Y/Z: 0.01 (no grating), 0.006 (with grating) B: 8” (with grating) | VDI3441 | |

| Repeatability (X/Y/Z) | mm | X/Y/Z: 0.006 (no grating), 0.004 (with grating) B: 6” (with grating) | VDI3441 | ||

| Tool magazine | Capacity | T | 60 | ||

| Tool length | mm | 500 | |||

| Tool diameter | mm | 105/210 | |||

| Tool weight | kg | 20 | |||

| other | System | – | Siemens 828D | ||

| Air source | Flow | L/min | 500 (ANR) | ||

| Pressure | MPa | 0.6~0.8 | |||

| Total electrical capacity | KVA | 75 | |||

| Size (L*W*H) | mm | 6575×4870×3300 | |||

| Total Weight | kg | 21500 | |||

Description

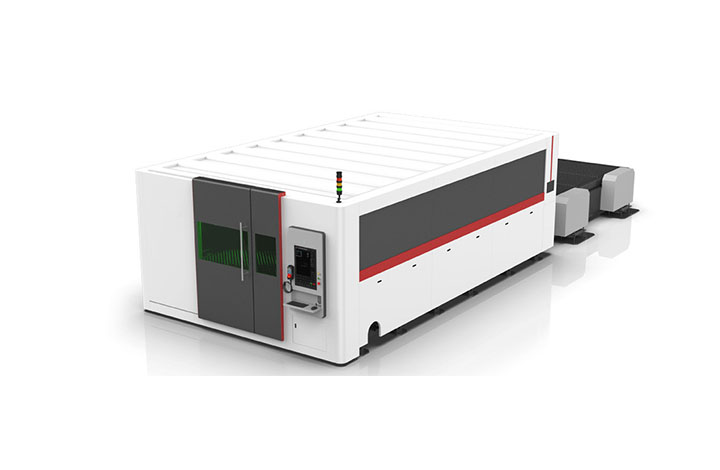

High speed High precision High efficiency

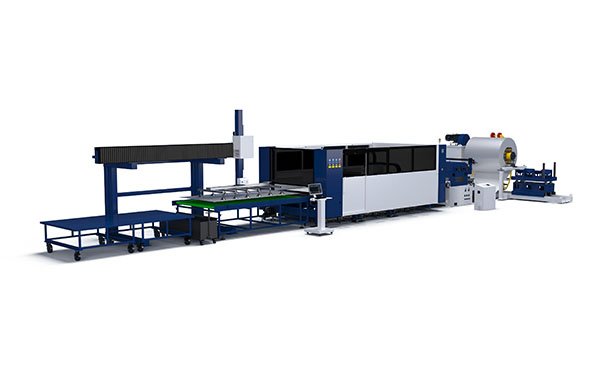

It is mainly used for part processing in industries such as construction machinery, automotive, energy, information, and molds. It is suitable for the machining of box-type and shell-type parts, especially ideal for processing complex and irregular-shaped parts.

High-Rigidity Structure

- Integrated Bed: Optimized design of internal ribs using FEM analysis, providing excellent stability.

- Lightweight Column: Double-layer wall structure design for the column, with multi-point radial rib arrangement and large-span cross-section layout at the bottom, offering light weight and high rigidity.

- High Dynamic Feed Axes: Three-axis linear guideways with a stepped layout for the X-axis, paired with the lightweight, high-rigidity column, ensuring excellent dynamic performance.

- Cam-Type APC: Stable and fast pallet exchange system.

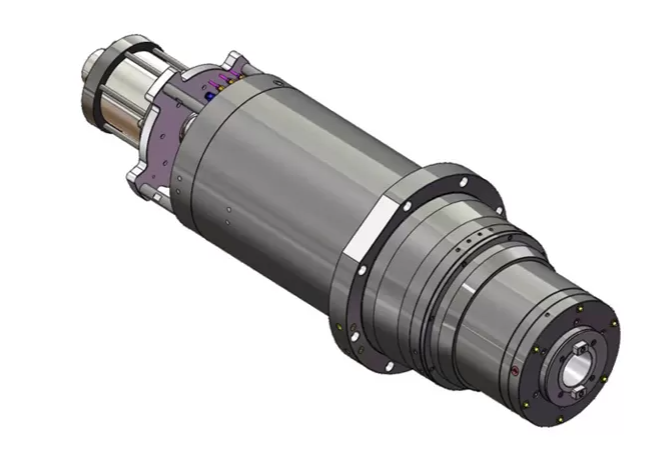

High-Torque Electric Spindle System

- Equipped with a high-power BT50 electric spindle, featuring automatic dual-winding switching, capable of meeting different requirements for high speed and high torque. The spindle offers high speed, high precision, and low noise performance.

- The standard temperature-controlled cooling system effectively reduces the spindle temperature, preventing thermal deformation and maintaining stable machining accuracy during extended operations.

- Additionally, various spindle options are available to handle different operating conditions, ensuring efficient and stable performance in diverse production environments.

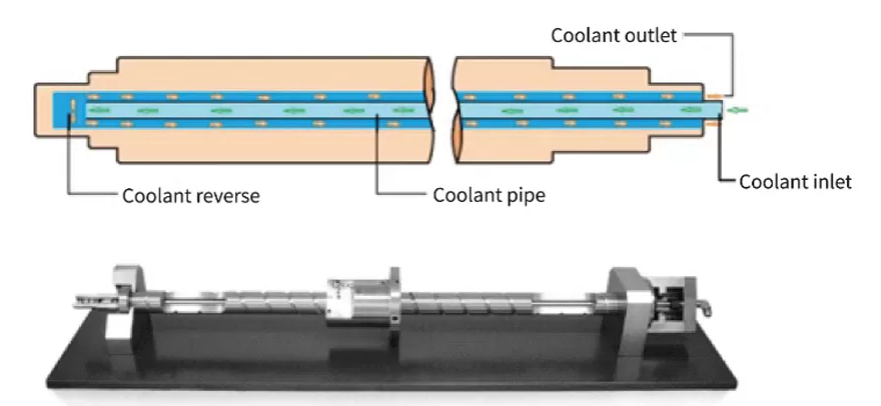

Accuracy and Stability

The three-axis ball screws feature a hollow cooling design, with a cooling unit circulating temperature-controlled coolant through the screw’s axis. This rapidly reduces the temperature rise of the ball screw during high-speed feed, maintaining a constant temperature and ensuring stable machining accuracy.

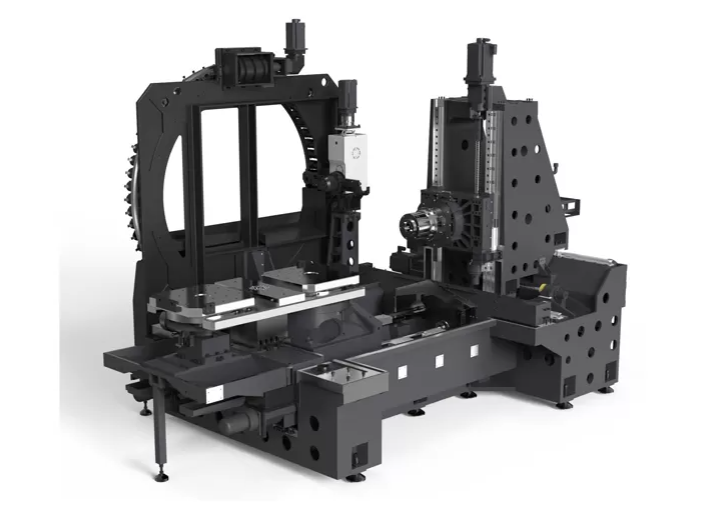

High-Precision Cam Rotary Table

- The system uses high-precision taper positioning pins combined with a hydraulic boost locking mechanism to ensure the worktable is firmly clamped, maintaining stability and vibration-free performance during machining.

- The cam-type CNC rotary table features a curved cam’s constant-speed drive surface and preloaded rolling contact transmission with needle bearings on the turret, offering high precision, high speed, zero backlash, and the ability to handle heavy loads.

- Additionally, a high-precision direct-drive rotary table is available as an option, equipped with a high-torque frameless direct-drive motor, large-diameter high-precision dedicated rotary table bearings, and a Renishaw circular grating for enhanced accuracy and stability.

Applications

Advantages

Continuous Innovation

High-tech enterprises, with a number of mature technical teams, annual research and development funds of 2 million, annual research and development of more than 12 new products, 20 national patent technology, continuous innovation.

6S Workshop Standard

36000 ㎡ workshop, 6S workshop standard, workshop through the ISO9001 quality system certification, with complete production equipment, products leave the factory after raw material inspection, process inspection, finished product inspection, products in line with GB and CE standard certification.

Self-built the Factory

Self-built the factory, through the whole industry chain, perfect casting factory, sheet metal factory, CNC machining center, cutting center, processing plant, accessories, the whole process of independent design and development, further reduce the cost, guarantee quality and improve the cost performance.

Our partners