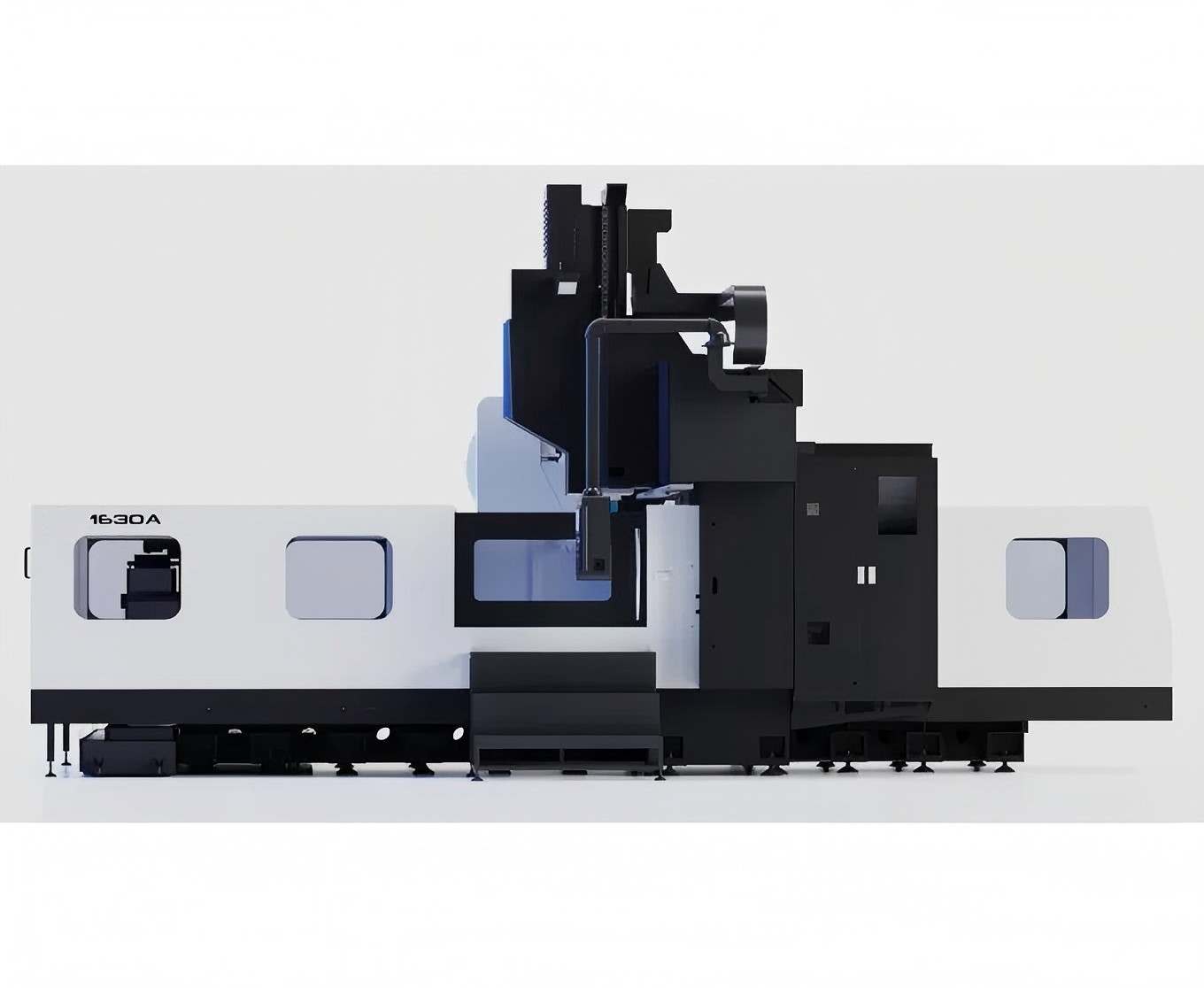

Technical Data

| Items | Unit | Machine Model: G-BU2030 | |||

| Travel | Table travel (X-axis) | mm | 3200 | ||

| Saddle travel (Y-axis) | mm | 2200 | |||

| Ram travel (Z-axis) | mm | 1000 | |||

| Spindle nose to table distance | mm | 100~1100 | |||

| Effective gantry width | mm | 3200 | |||

| Table | Table size | mm | 2000*3000 | ||

| Max. load | kg/m2 | 5000 | |||

| T-slot | mm | 28 | |||

| Spindle | Spindle power | KW | 30 | ||

| Max. speed | r/min | 18000 | |||

| Torque output | Nm | 72/85 | |||

| Ram section | mm | 420×420 | |||

| Spindle taper | HSK-A63 | ||||

| Speed | Feed rate range (Cutting) | mm/min | 20/20/20 | ||

| Rapid traverse speed (X/Y/Z-axis) | mm/min | 24000/24000/24000 | |||

| Accuracy | Positioning accuracy | With scale | mm | 0.020/0.015/0.01 | |

| Without scale | mm | 0.03/0.025/0.02 | |||

| Repeatability | With scale | mm | 0.013/0.011/0.009 | ||

| Without scale | mm | 0.018/0. 015/0.012 | |||

| Others | Z-axis counterweight | Hydraulic + nitrogen balance | |||

| CNC system | SIEMENS ONE | ||||

| Air supply | Flow | L/min | 500 | ||

| Pressure | MPa | 0.45~0.8 | |||

| Coolant tank capacity | L | 140 | |||

| Machine size(L×W×H) | mm | 8500×6600×5200 | |||

| Machine weight (approx.) | kg | 35000 | |||

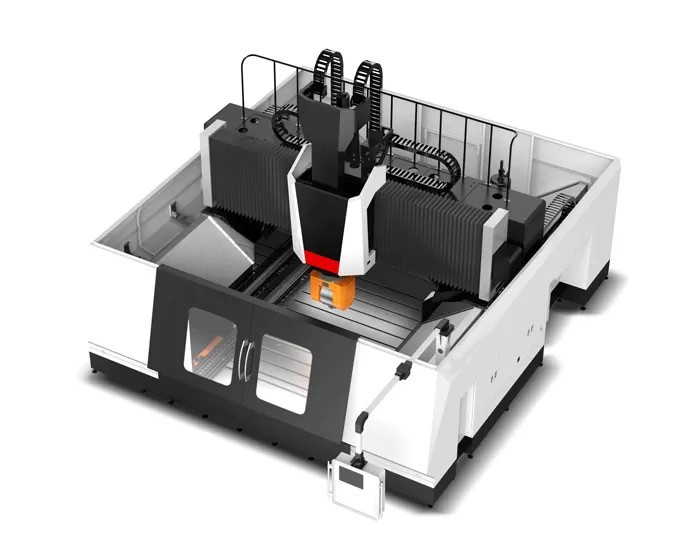

Description

Primarily used for machining complex parts, aluminum and its alloys, as well as difficult-to-machine materials. It is capable of high-precision and high-efficiency machining of complex spatial surfaces.

Characters

Machine Structure

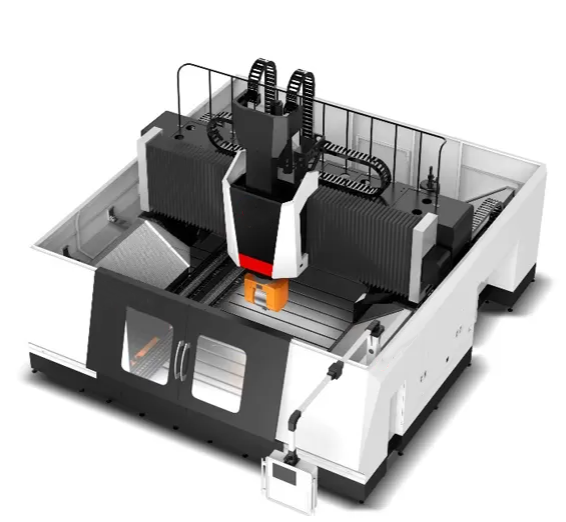

- The machine features an overhead gantry frame structure with a fixed worktable.

- Major components are made of high-strength cast iron.

Spindle Unit

- The spindle unit uses a Zhongke Ibeg T70.5 5-axis linked A/C double swivel milling head, which can achieve 5-axis linked machining of complex surfaces.

- With high-precision encoders and a hydraulic clamping system, the A and C axes can be clamped at any angle within their operating range (C axis ±360°, A axis ±110°).

- Standard 18000rpm motorized spindle, capable of high-precision, fast, and continuous cutting.

- Independent hydraulic pump station ensures safe and reliable tool clamping.

- Motorized and A/C axis drives are equipped with a temperature control cooling system.

Guideway

- All XYZ axes are equipped with heavy-duty roller linear guideways,

- The Y-axis crossbeam guideway uses a stepped arrangement with a wide guideway span to enhance load capacity.

- The Z-axis saddle guideway features 4 guideways installed at 90° with 12 linear blocks to support Z-axis guideways, providing strong spindle rigidity and good high-speed performance.

Ballscrews

XY axes use a large lead ball screw drive structure.

The Z axis uses a direct motor-ball screw drive.

Applications

Advantages

Continuous Innovation

High-tech enterprises, with a number of mature technical teams, annual research and development funds of 2 million, annual research and development of more than 12 new products, 20 national patent technology, continuous innovation.

6S Workshop Standard

36000 ㎡ workshop, 6S workshop standard, workshop through the ISO9001 quality system certification, with complete production equipment, products leave the factory after raw material inspection, process inspection, finished product inspection, products in line with GB and CE standard certification.

Self-built the Factory

Self-built the factory, through the whole industry chain, perfect casting factory, sheet metal factory, CNC machining center, cutting center, processing plant, accessories, the whole process of independent design and development, further reduce the cost, guarantee quality and improve the cost performance.

Our partners