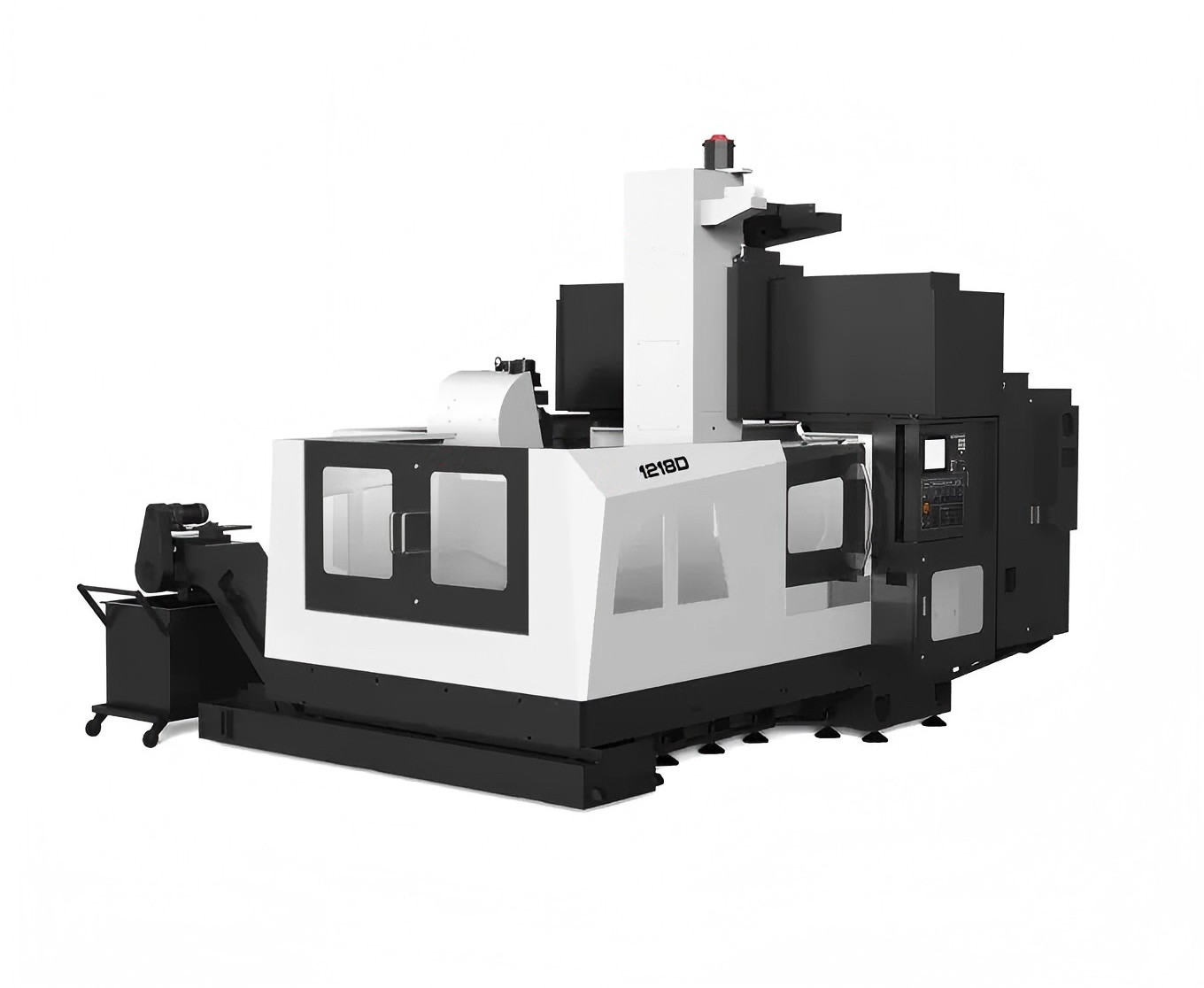

Technical Data

| Items | Unit | Machine Models | ||||

| GMC-1630A | GMC-1630B | GMC-1630C | ||||

| Travel | X-axis travel (Table longitudinal) | mm | 3200 | |||

| Y-axis travel (Crossbeam transverse) | mm | 1800 | ||||

| Z-axis travel (Ram vertical) | mm | 800 | ||||

| Distance from spindle end to table | mm | 100~900 | 70~870 | |||

| Effective gantry width | mm | 1800 | ||||

| Table | Table size (L×W) | mm | 3000×1600 | |||

| Max. load | kg | 8000 | ||||

| T-slot (Width×Pitch×Qty) | mm | 22×160×9 | ||||

| Spindle | Drive type | / | Belt driven | Gear driven | Motorized spindle | |

| Max. spindle speed | r/min | 6000 | 6000 | 15000 | ||

| Spindle power (Rated/Peak) | kW | 15/18.5 | 15/22 | |||

| Torque output (Rated/Peak) | N.m | 191/315 | 573/945 | 45.7/73.6 | ||

| Spindle taper | / | BT50 | BBT40 | |||

| ATC (Opt.) | Number of tools | T | 24 | |||

| Max. tool dia. (Full/Adjacent) | mm | Φ110/Φ200 | Φ80/Φ150 | |||

| Max. tool length | mm | 350 | 250 | |||

| Max. tool weight | kg | 18 | 8 | |||

| Speed | Feed rate range (Cutting) | m/min | 10 | |||

| Rapid traverse speed (X/Y/Z-axis) | m/min | 16/16/12 | ||||

| Accuracy | Positioning accuracy | mm | 0.02/0.015/0.012 | |||

| Repeatability | mm | 0.012/0.008/0.008 | ||||

| Others | Z-axis counterweight | / | Nitrogen balance | |||

| CNC system | / | FANUC 0i-MF PLUS (Opt. Mitsubishi M80, Siemens 828D) | ||||

| Air supply | Flow | L/min | 280 (ANR) | |||

| Pressure | MPa | 0.5~0.8 | ||||

| Total electrical capacity | kVA | 40 | ||||

| Coolant tank capacity | L | 400 | ||||

| Machine size | Length | mm | 7800 | |||

| Width | mm | 5400 | ||||

| Height | mm | 4550 | ||||

| Machine Enclosure | – | Full perimeter sheet metal | ||||

Continuous Innovation

High-tech enterprises, with a number of mature technical teams, annual research and development funds of 2 million, annual research and development of more than 12 new products, 20 national patent technology, continuous innovation.

6S Workshop Standard

36000 ㎡ workshop, 6S workshop standard, workshop through the ISO9001 quality system certification, with complete production equipment, products leave the factory after raw material inspection, process inspection, finished product inspection, products in line with GB and CE standard certification.

Self-built the Factory

Self-built the factory, through the whole industry chain, perfect casting factory, sheet metal factory, CNC machining center, cutting center, processing plant, accessories, the whole process of independent design and development, further reduce the cost, guarantee quality and improve the cost performance.

Our partners