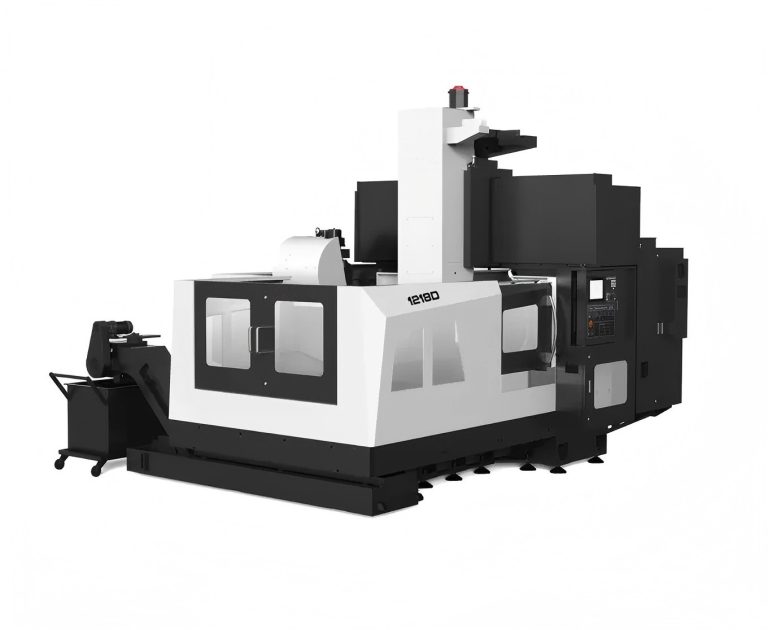

Technical Data

| Items | Unit | Machine Models | |||||||

| GMC-1218D | GMC-1220D | GMC-1225D | GMC-1230D | GMC-1630D | GMC-1220D(BT50) | ||||

| Travel | X-axis travel | mm | 1800 | 2100 | 2600 | 3150 | 3150 | 2100 | |

| Y-axis travel | mm | 1380 (+50 Tool change) | 1500 | 1800 | 1500 (+50 Tool change) | ||||

| Z-axis travel | mm | 700 | 700 | ||||||

| Distance from spindle end to table | mm | 150~850 | 195~895 | 100~800 | |||||

| Effective gantry width | mm | 1350 | 1560 | 1800 | 1560 | ||||

| Table | Table size (L×W) | mm | 1800*1250 | 2000*1250 | 2500*1250 | 3000*1250 | 3000*1600 | 2000*1250 | |

| Max. load | kg | 4000 | 4000 | 5000 | 6000 | 8000 | 4000 | ||

| T-slot (Width×Pitch×Qty) | mm | 22×160×7 | 22×160×7 | 22×160×9 | 22×160×7 | ||||

| Spindle | Drive type | / | Direct connection | Direct connection | |||||

| Max. spindle speed | r/min | 12000 | 8000(Opt.10000) | ||||||

| Spindle power (Rated/Peak) | kW | 11/15 | 15/18.5(Opt.11/15) | ||||||

| Torque output (Rated/Peak) | N.m | 52.5/95.5 | 143/236(Opt.52.5/95.5) | ||||||

| Spindle taper | / | BBT40/BT40 | BT50(Opt.BBT50) | ||||||

| ATC (Opt.) | Number of tools | T | 24 | Opt.24 | |||||

| Max. tool dia. (Full/Adjacent) | mm | Φ80/Φ150 | Opt.Φ110/Φ200 | ||||||

| Max. tool length | mm | 250 | Opt.350 | ||||||

| Max. tool weight | kg | 7 | Opt.18 | ||||||

| Speed | Feed rate range (Cutting) | m/min | 10 | 10 | |||||

| Rapid traverse speed (X/Y/Z-axis) | m/min | 20/16 | 16/16/12 | 16/16/12 | |||||

| Accuracy | Positioning accuracy | mm | 0.015/0.012/0.012 | 0.02/0.015/0.012 | 0.015/0.012/0.012 | ||||

| Repeatability | mm | 0.008/0.008/0.008 | 0.012/0.008/0.008 | 0.008/0.008/0.008 | |||||

| Others | Z-axis counterweight | / | Nitrogen balance | Nitrogen balance | |||||

| CNC system | / | FANUC 0i-MF PLUS (Opt. Mitsubishi M80, Siemens 828D) | Mitsubishi M80 | ||||||

| Air supply | Flow | L/min | 280(ANR) | 280(ANR) | |||||

| Pressure | MPa | 0.5~0.8 | 0.5~0.8 | ||||||

| Total electrical capacity | kVA | 40 | 40 | ||||||

| Coolant tank capacity | L | 400 | 400 | ||||||

| Machine size | Length | mm | 5000 | 5100 | 6300 | 7800 | 7800 | 5100 | |

| Width | mm | 4700 | 4900 | 5400 | 4800 | ||||

| Height | mm | 4400 | 4550 | 4550 | 4550 | ||||

| Machine Enclosure | – | Full perimeter sheet metal | Full perimeter sheet metal | ||||||

Description

The machine series is mainly used for high-speed and high-precision machining of parts in industries such as automotive components, molds, construction machinery, valves, rail transit, energy, agricultural machinery, and coal mining machinery.

Characters

Machine Structure

- Integrated Design: The machine features a gantry-type structure with an integrated column and crossbeam, enhancing overall rigidity.

- Z-Axis Balance System: Utilizes nitrogen pressure to counterbalance the weight of the spindle box and ram, reducing the load on the servo motor. This minimizes vibration and deformation, improving machining accuracy and stability. Additionally, it reduces mechanical wear, extending the machine’s service life.

3-Axis Motion System

- 3-Axis Guideway: Adopts a roller-type linear guide design, providing fast dynamic response and high precision, ensuring smooth operation without creeping.

- Drive System: The servo motor is directly coupled with a high-precision ball screw, combined with a fixed pre-tensioned structure at both ends, achieving high transmission accuracy and stability.

High-Speed Directly Coupled Spindle

- High-Speed Spindle: BT40 direct- coupled spindle with a maximum speed of 12,000 r/min, delivering excellent cutting efficiency and performance.

- Coolant Prevent: The spindle front end features a labyrinth seal structure and an air curtain protection system, effectively preventing coolant from entering the spindle bearings, extending service life.

- Thermal Control: Equipped with a central air-blow function and an automatic circulation cooling system, significantly reducing temperature rise and thermal deformation, ensuring high machining accuracy and stability.

ATC

24-Tool Disc magazine

Advantages

Continuous Innovation

High-tech enterprises, with a number of mature technical teams, annual research and development funds of 2 million, annual research and development of more than 12 new products, 20 national patent technology, continuous innovation.

6S Workshop Standard

36000 ㎡ workshop, 6S workshop standard, workshop through the ISO9001 quality system certification, with complete production equipment, products leave the factory after raw material inspection, process inspection, finished product inspection, products in line with GB and CE standard certification.

Self-built the Factory

Self-built the factory, through the whole industry chain, perfect casting factory, sheet metal factory, CNC machining center, cutting center, processing plant, accessories, the whole process of independent design and development, further reduce the cost, guarantee quality and improve the cost performance.

Our partners