Description

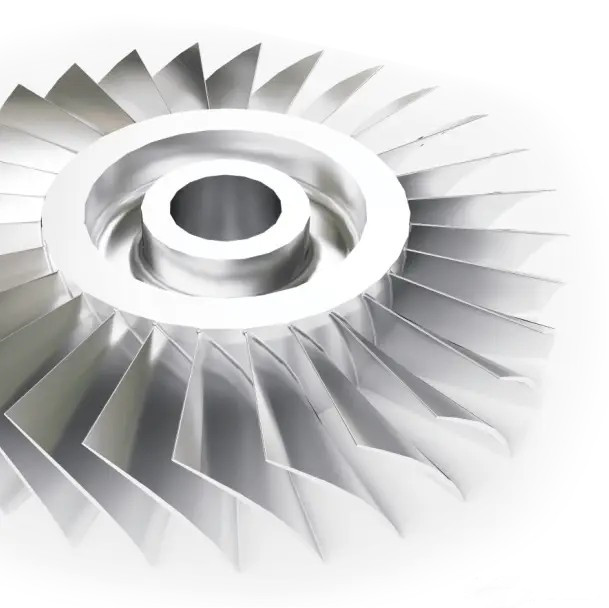

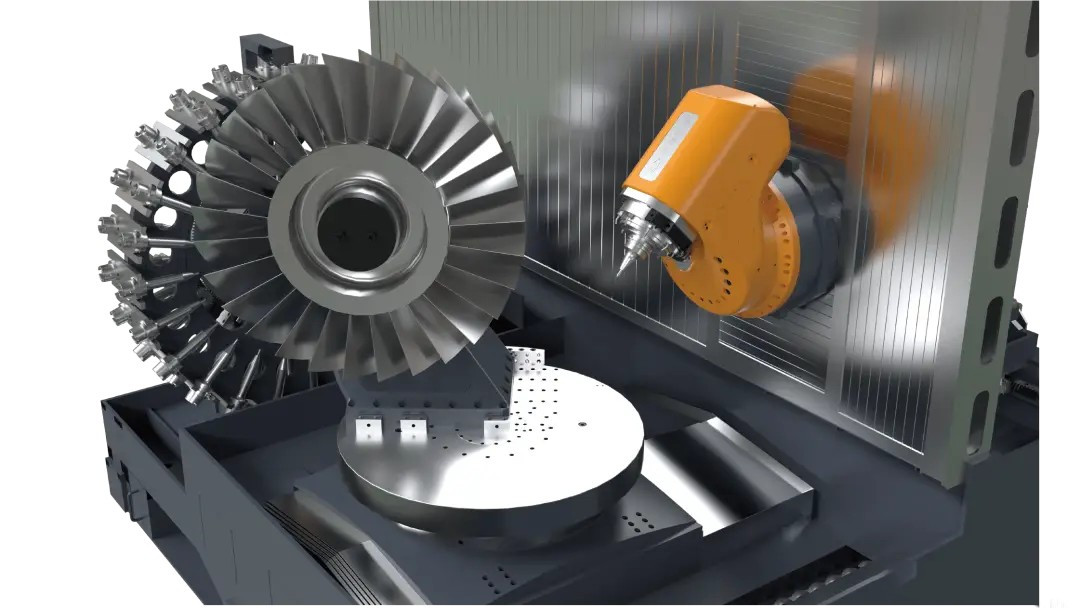

- CLGD1200 six-axis five-linkage blisk machining center is a special machine product developed for large-scale blisk processing, which should mainly meet the ultra-high requirements for the movement speed and acceleration range of each physical axis when the existing machine tool is performing the five-axis processing blisk action. It is a customized machine tool solution jointly created by Chenglong CNC and users to ensure that users maintain a key competitive advantage in machining.

- Blisk machining centers can be used to keep the tool and the 45 attachment head rotation centers as close as possible with longer tools, thus reducing the speed and acceleration requirements of RTCP actions on the linear axes. Blisk machining center has obvious advantages when machining large blisk disc, especially in the position that the rotation axis of the front trailing edge of the blade moves larger, the advantage is more obvious, and when using blisk machining center to process blisk, the movement speed and acceleration of each physical axis can be kept in a low range relative to the existing machine tool.

Character

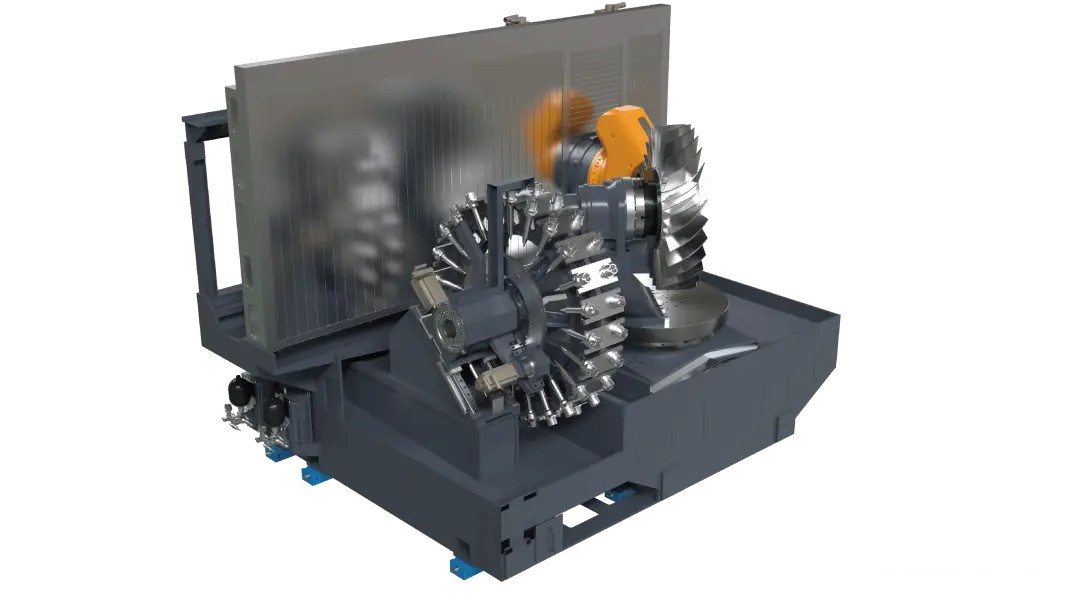

Optimum stability and optimum force transfer

The overall layout of the machine tool is the overall layout of the movement of the column of the mature flat bed, and the spiral chip removal with a large inclination angle is used on both sides of the horizontal bed, and the chip removal is smooth. The linear guide of the moving column is equipped with 6 slides, which gives the machine the highest stability and the best force transmission from the cutting spindle to the machine bed. The slide table moves left and right along the bed (X-axis), the column moves back and forth along the slide table (Z-axis), the swing head moves up and down along the column (Y-axis), the 45 single swing head A axis is installed on the saddle, the turntable B axis is installed on the slide table, and the workpiece axis C axis is vertically installed on the workpiece axis. The machining point is near the central axis of the swing head and the central axis of the turntable, and the force direction is near the workpiece axis, the machine tool mechanism has good stress conditions, and the working area of the machining point is small, which reduces the requirements for X/V/Z three-axis speed and acceleration.

High-precision and high-speed milling machining

The 45° swing head A axis, the turntable B axis, the workpiece axis C axis and the motor spindle direct drive technology are directly driven by the torque motor, and the XY/Z three-linear axis adopts direct drive technology, and the workpiece axis does not participate in the linkage, and the remaining five axes realize the five-axis linkage. High-resolution and high-precision position feedback technology, full closed-loop, thermal deformation compensation and other technologies realize the high-precision and high-speed milling of the whole machine. It can process complex space surfaces to improve the performance and processing efficiency of the whole machine.

High-precision and high-speed milling machining

- The 45° swing head A axis, the turntable B axis, the workpiece axis C axis and the motor spindle direct drive technology are directly driven by the torque motor, and the XY/Z three-linear axis adopts direct drive technology, and the workpiece axis does not participate in the linkage, and the remaining five axes realize the five-axis linkage. High-resolution and high-precision position feedback technology, full closed-loop, thermal deformation compensation and other technologies realize the high-precision and high-speed milling of the whole machine. It can process complex space surfaces to improve the performance and processing efficiency of the whole machine.

- The high-torque turntable and workpiece shaft developed by the machine tool are designed with a high-rigidity structure. The turntable is controlled in a closed loop with an absolute encoder to achieve high positioning accuracy and repeatability. The workpiece shaft is equipped with a zero-point positioning quick-change workbench, the clamping method adopts hydraulic expansion sleeve enveloping locking, and the absolute encoder is used for closed-loop control, which can realize the high positioning accuracy and repeated positioning accuracy of the quick replacement workbench.

Double-row disc tool changer with numerical control system

The machine tool changer is equipped with 48 double-row disc changers as standard, which are fast and smooth, and the disc tool changer is servo-driven by linear and rotary axes, and the linear axes are equipped with grating scales for closed-loop precise positioning. The base of the disc tool magazine is fixed on the machine tool base, the tool spindle is closer to the tool change point of the tool magazine, and the tool spindle and the linear axis and the rotary axis of the tool magazine can pick up the tool by itself, and the manipulator is not required to transmit twice, which greatly improves the tool change time

Double-row disc tool changer with numerical control system

The machine adopts a domestic bus-type high-end CNC system, which can realize the linkage of X, Y, Z, A, B five coordinates at the same time, and can use the method of linear interpolation and arc interpolation to process contours and three-dimensional surfaces.

Application

CLGD1200 6-axis 5-linkage blisk machining center is mainly used in the aerospace industry for the processing of large-scale blisk products. Its working performance has a five-axis milling function, which realizes the five-axis milling of complex parts. It can be used for milling, boring, drilling, reaming, countersinking and other processes, especially suitable for processing blisk parts and parts with multi-profile features. The machine tool has high speed and high torque, and the workpiece shaft adds zero point positioning system and worktable quick change system, which can effectively shorten the production and processing cycle.

This type of machine tool plays a pivotal role and is necessary in the aerospace field. With the continuous progress of science and technology and the development of the aerospace field, the products of the six-axis five-linkage blisk machining center are expected to help China’s aerospace manufacturing field achieve more breakthroughs and innovations in the future.

Broad application prospects