Technical Data

| Items | Machine Model:CL-170 |

| X/Y/Z axis travel | 1700×1700×1100mm |

| Distance from horizontal milling head center to working table | 130~1230mm |

| Rotary table speed | 53rpm |

| Working table size | φ1700mm |

| Max table load | Milling 8000kg |

| Swing milling head (B axis) | Standard |

| Swing range (0=Vertical/180=Level) | -15°~ +180° |

| B axis rated speed | 60rpm |

| Distance from vertical spindle nose to table | 236~1336mm |

| Electric spindle Max. speed | 10000rpm |

| Power(S1-100%/40%DC) | 48/71kW |

| Torque(S1-100%/40%DC) | 300/452Nm |

| Spindle taper | 1:10 Taper |

| Tool interface | HSK100A |

| Tool magazine capacity | 40T |

| Max. tool diameter/length/weight | φ135mm/300mm/12kg |

| Tool changing time (Tool to Tool) | 4s |

| Drilling (Normalizing medium carbon steel) | φ50mm |

| Tapping (Normalizing medium carbon steel) | M40 |

| Rapid traverse | 40m/min |

| X/Y/Z positioning accuracy | 0.012mm |

| X/Y/Z repeat positioning accuracy | 0.01mm |

Description

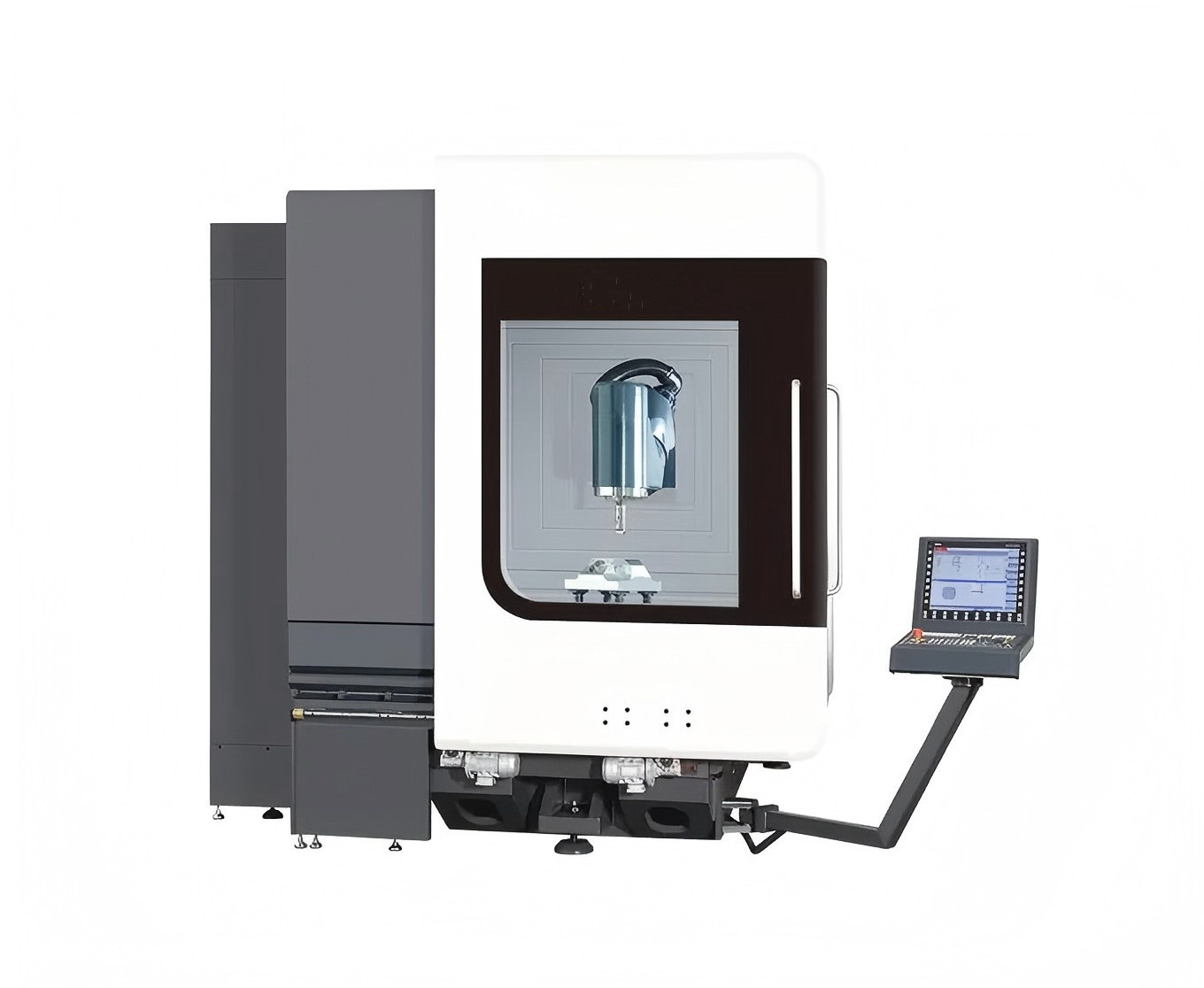

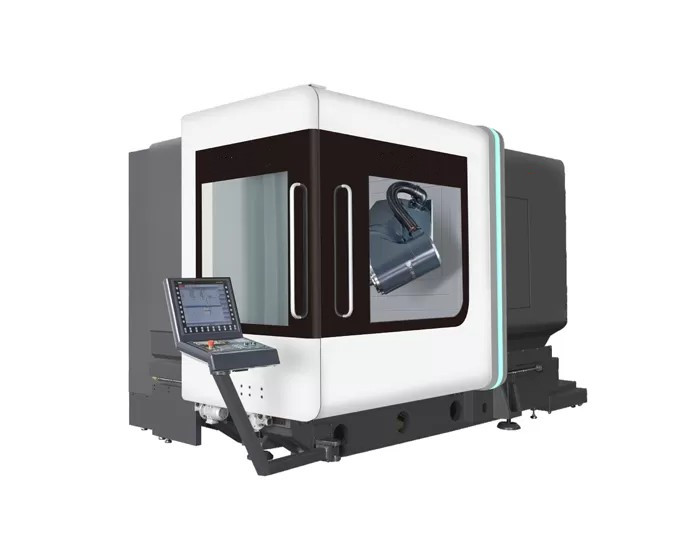

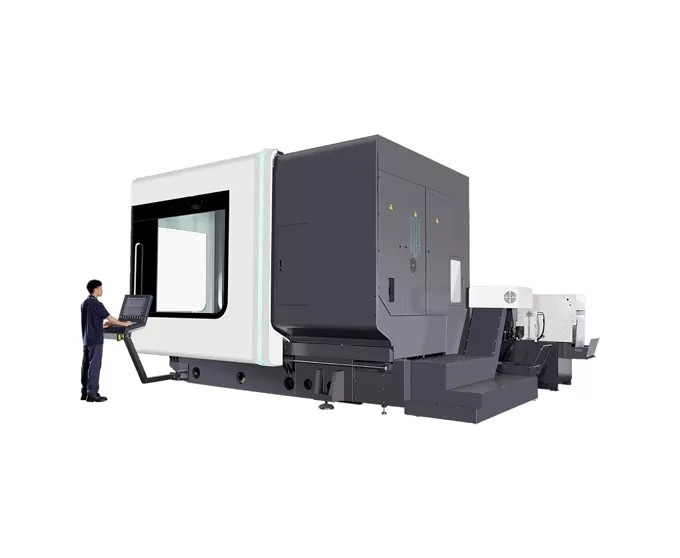

The advanced and highly stable 5-axis machine mechanism, with a simple man-machine operation mode, focuses on improving accuracy, performance and efficiency by 30% each, achieving the highest machining performance and part accuracy under high dynamic conditions. From the hardto-cut materials in the aviation industry to the highest surface quality requirements in the mold manufacturing industry, five-axis simultaneous milling-turning compound machining center provides the best conditions. Five-axis linkage turning and milling compound machining center can realize multi-form use: vertical and horizontal conversion, milling and turning, one-time clamping, multi-process and multi-angle processing and forming.

Character

Optimal Mechanical Casting Design

- The bed is made of a new mineral casting structure, while moving parts use Meehanite-grade high-quality cast iron.

- Tempered and naturally aged to eliminate internal stresses.

- Materials with natural frequency to eliminate vibration-induced processing stresses.

- The large-area, high-rigidity column design effectively improves rigidity and static/dynamic precision.

- Three-axis hollow cooling ballscrew drive.

Powerful 5-Axis Milling Head

SIGNIFICANTLY IMPROVED AND IMPROVED INTERFERENCE PROFILE AND RIGIDITY

The B-axis with direct drive of DD motor improves rigidity through larger YRT bearing, which can realize high-torque cutting under the linkage state.

Turning and Milling Table

- Independently designed and manufactured.

- Internal DD motor with zero backlash, direct drive design.

- High acceleration and deceleration response characteristics.

- Larger YRT bearings for improved rigidity.

- High rated drive torque with positioning and clamping device for the worktable.

- Supports both milling and turning operations, reducing workpiece handling and improving product precision.

Automatic Tool Change System

- Tool selection and change are controlled by a servo motor for more stable and accurate operation.

- With Siemens ONE’s tool management feature, tool management is more efficient.

Applications

Advantages

Continuous Innovation

High-tech enterprises, with a number of mature technical teams, annual research and development funds of 2 million, annual research and development of more than 12 new products, 20 national patent technology, continuous innovation.

6S Workshop Standard

36000 ㎡ workshop, 6S workshop standard, workshop through the ISO9001 quality system certification, with complete production equipment, products leave the factory after raw material inspection, process inspection, finished product inspection, products in line with GB and CE standard certification.

Self-built the Factory

Self-built the factory, through the whole industry chain, perfect casting factory, sheet metal factory, CNC machining center, cutting center, processing plant, accessories, the whole process of independent design and development, further reduce the cost, guarantee quality and improve the cost performance.

Our partners