Technical Data

| ltems | Unit | Value |

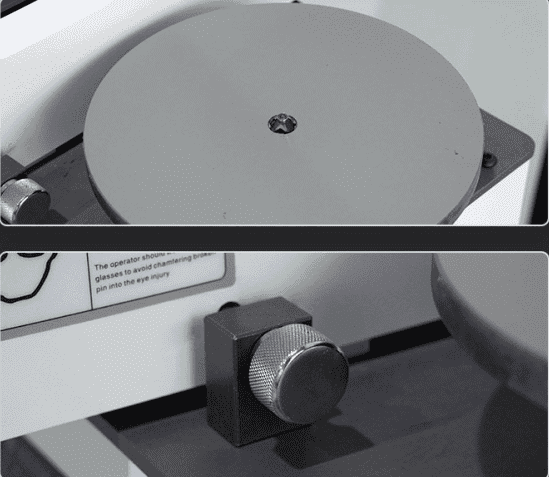

| Guide Rail | / | V-groove slide/Disc |

| Chamfering Type | / | Straight/curved edge |

| Input Voltage | V/Hz | 380/50 |

| Rated Power | W | 750 |

| Rated Speed | rpm | 10000 |

| Chamfering Angle | ℃ | 45℃ |

| / | Straight/curved edge | |

| Chamfering Depth | mm | Linear part: C0-C6(Al); C0-C5(steel) |

| mm | Curved part: R2, R3/C0-3 | |

| Blade Model | / | Linear part: SPHW120FN-4.4 |

| / | Curved part: DCMT070204 | |

| Slide Rail Travel | mm | 200 |

| Packing Dimensions | 600x550x550 | |

| Net Weight | KG | 68 |

Description

Compund Chamfering Machine CM900DG has a multi-functional design, integrating chamfering straight angles, arcs, and irregular curves on a single machine, which can replace CNC machining centers. This machine can chamfer and deburr various materials, such as iron, aluminum, copper, carbon steel, stainless steel, aluminum alloy, powder metallurgy materials, plastic, nylon, etc.

Adjustable Arc and Linear Trimming

The chamfering depth is adjustable between 0-6mm.

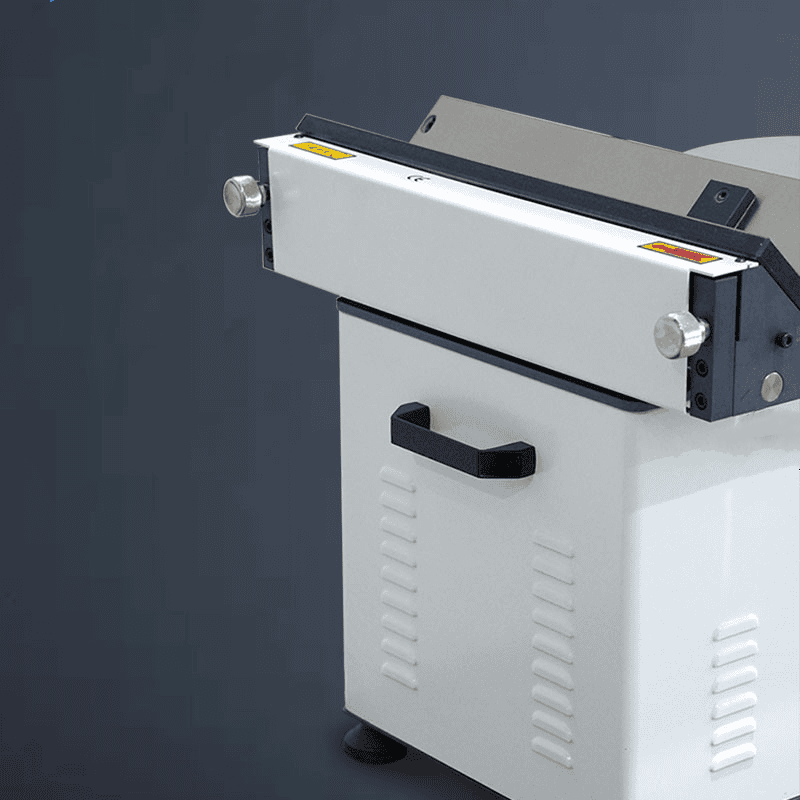

Sliding rail design

Sliding chamfers do not damage the surface of the workpiece, making work easier.

Multi-functional design

Integrating chamfering straight angles, arcs, and irregular curves on a single machine, which can replace CNC machining center

Efficient and Time-Saving

High precision, high speed, low noise, and high surface finish of the processed part.

Applications

Advantages

Continuous Innovation

High-tech enterprises, with a number of mature technical teams, annual research and development funds of 2 million, annual research and development of more than 12 new products, 20 national patent technology, continuous innovation.

6S Workshop Standard

36000 ㎡ workshop, 6S workshop standard, workshop through the ISO9001 quality system certification, with complete production equipment, products leave the factory after raw material inspection, process inspection, finished product inspection, products in line with GB and CE standard certification.

Self-built the Factory

Self-built the factory, through the whole industry chain, perfect casting factory, sheet metal factory, CNC machining center, cutting center, processing plant, accessories, the whole process of independent design and development, further reduce the cost, guarantee quality and improve the cost performance.

Our partners